—

FELDER - FORMAT4

profit H22 XYLMAC

Machining center for windows and doors

Code: 583

restore Production year: 2009 error_outline Status: Discreet

domain Availability: Incoming check_circle EC legislation: Compliant

Controlled axes number:

4

Arms number:

6

Description

Machining center for windows and doors

FELDER – FORMAT4 profit H22 XYLMAC

The base of the H22 profit machining center is made up of high-thickness, electrically welded tubular sections.

X-axis guide system:

The X-axis arm is driven by a rack with inclined and curved teeth.

Y-axis guide system:

The Y axis is positioned with a ground ball screw.

Z axis sliding system:

The Z axis is positioned via a smooth ball screw.

Automatic centralized lubrication.

Mobile control terminal for flexible machine control.

Remote control for remote control of the axes.

Remote assistance package via Internet.

Laser alignment for processing of arched frames (for windows and doors).

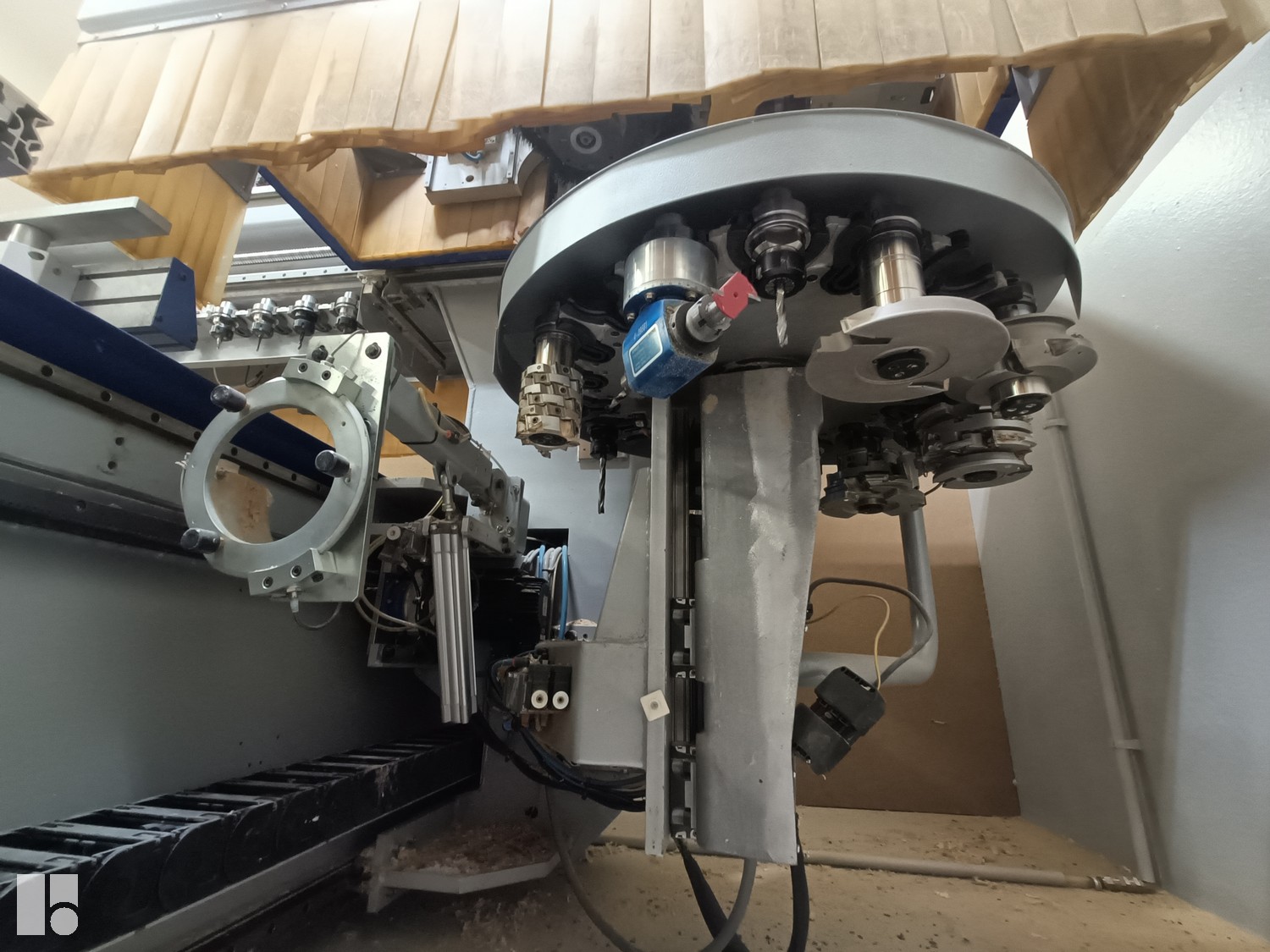

Interpolating C axis for electrospindle 0°–360°.

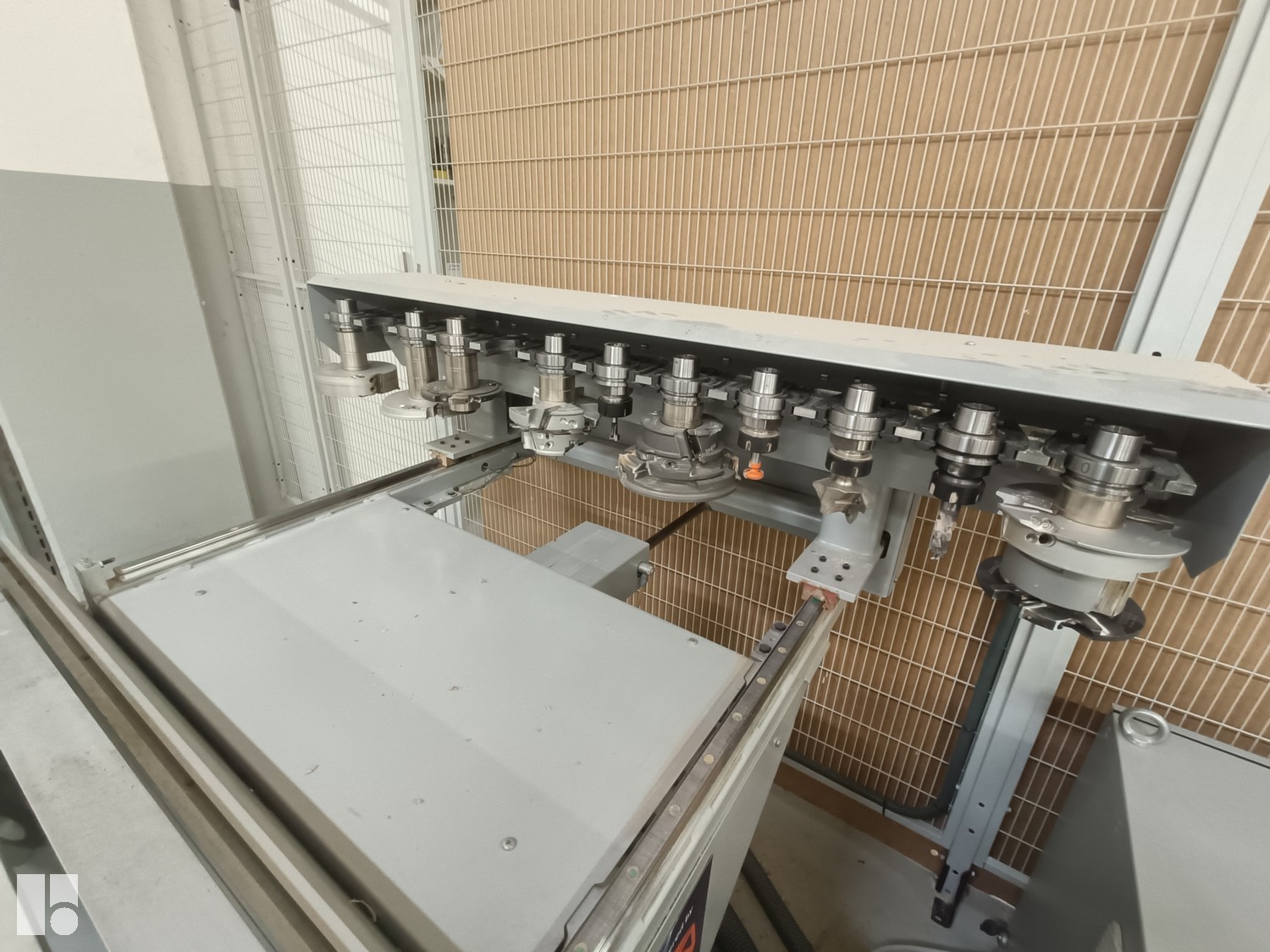

Revolver tool changer with 18 positions mounted on the beam for HSK F63.

Direct horizontal motor with one output, 4.5 kW.

Chip guard device

Technical details

Effective working

Effective X

3060 mm

Eeffective Y

1210 mm

Effective Z

100 mm

Details

Heads number

1

Controlled axes number

4

Main motor power

12 kW

Mils connection drive motor

HSK 63F

Horizontal motors (Optional)

check_circle

Tools warehouse positions number

8+12+18+2

Arms number

6

Suction quantity

12

Grips number (Optional)

8

Security

Sapety mats

Vacuum pump

1 x 90 mc3

Software/C.N.

Software

WOOD FLASH

Generals

Sizes*

6000x4500x2350 mm

Weight*

3600 kg

Total kW*

21

*Shown values may vary depending on the configuration of the machine.

Related machineries

FELDER - FORMAT4 PROFIT H08 16.31

CNC / Pantographs

Nesting CNC Machining Centre

FELDER - FORMAT4 PROFIT H08 16.31

CNC / Pantographs

CNC-NESTING – EFFICIENCY THROUGH AUTOMATION

Especially developed for universal application, this profitable CNC all-rounder convinces with top precision and impressive productivity when processing various different materials.

The profit H08 16.31 offers maximum flexibility and efficiency and already convinces in the basic equipment with 11 tool positions. For perf...

FELDER - FORMAT4 profit H350 16.30

CNC / Pantographs

Work center for windows and doors

FELDER - FORMAT4 profit H350 16.30

CNC / Pantographs

CNC machining center with a gantry structure (toolless) and digital drives (two-sided drive).

The machine base of the Profit H350 16.30 is made of thick-walled, electro-welded shaped tubes.

Steel ribs inside the base ensure high stability.

Machine composition:

Optical machine status indicator

Blue LED lighting strip, integrated into the front mount ...

MARZANI MULTICENTER 300 2F

CNC / Pantographs

Work center for windows and doors

MARZANI MULTICENTER 300 2F

CNC / Pantographs

Machine provided with a steel skeleton with sliding guides on tracks and ball sliding blocks.

Axes movement by means of ball screws controlled by C.C. motors and decimal resolution Encoder.

Machine tasks controlled by a personal computer with Windows 10

Linear and circular interpolation on each milling axis.

Machine made of:

Horizontal milling tool with kW 3,3 high-f...

Request infos

FELDER – FORMAT4 profit H22 XYLMAC