—

FELDER - c-tech

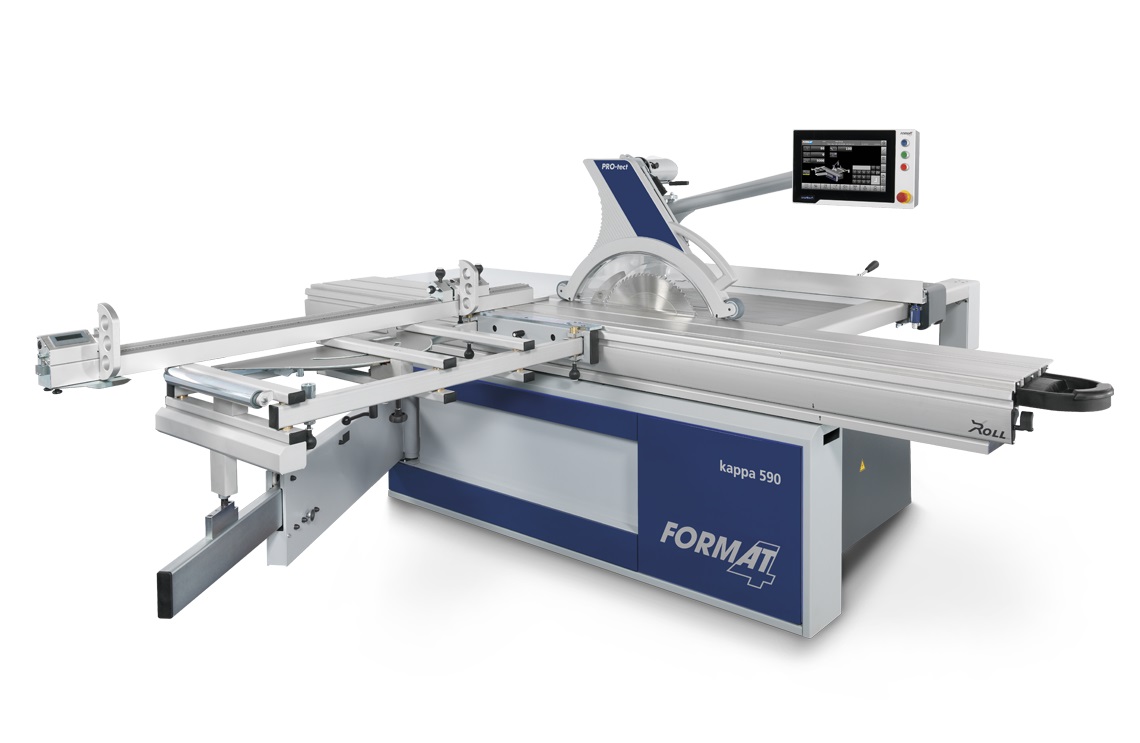

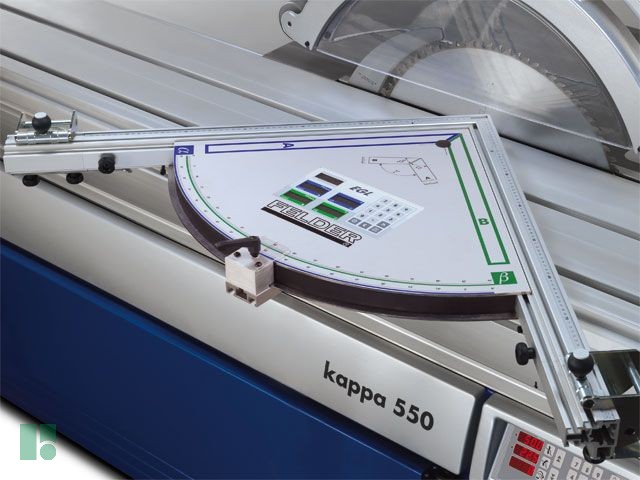

kappa 590 x-motion

c-tech Sliding Table Panel Saw, for composite aluminium panel maker (Alucobond®, dibond® etc), fibrocement, plasterboard, soundproof ingering panels, high-pressure plastic laminate (HPL), aluminum honeycomb (Alucore®, Larcore®, Plascore®) and Corian®

Wagon length:

3200 mm

Parallel guidance cut wedth:

1250 mm

Blade diameter:

550 mm

Automatic parallel guidance

Description

c-tech Sliding Table Panel Saw, for composite aluminium panel maker (Alucobond®, dibond® etc), fibrocement, plasterboard, soundproof ingering panels, high-pressure plastic laminate (HPL), aluminum honeycomb (Alucore®, Larcore®, Plascore®) and Corian®

FELDER – c-tech kappa 590 x-motion

The ingenious panel saw with double pivoting for angle cuts in all positions

With innovative details, the new kappa 590 becomes the new benchmark for Premium Sliding Table Panel Saws. The new twin-pivot unit has a total swivel range of 92° and achieves a cutting height up to 202 mm for saw blades with a diameter of 550 mm. This saves valuable working time and simplifies the cutting of internal mitre and simple compound cuts.

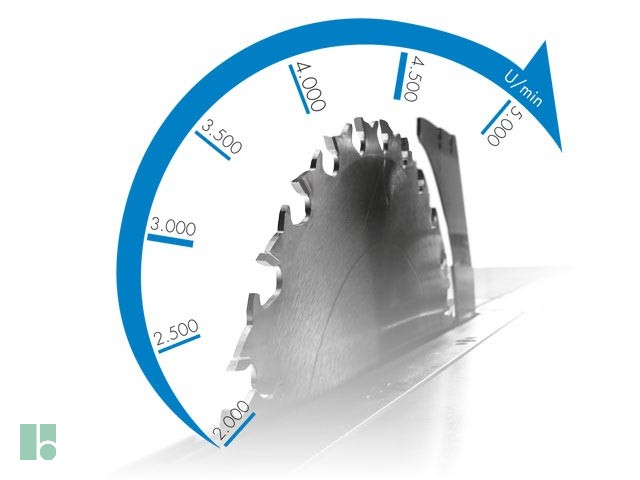

The highly efficient synchronous motor with continuously adjustable speed control from 2,000 to 5,000 rpm guarantees constant high performance and best power transmission with state-of-the-art Poly-V-belt technology.

All axes of the machine can be controlled ergonomically and intuitively by the central operating unit with 15 "touch screen. The in-house software with graphical user interface, a multitude of programs, a USB interface and the prepared network connection make work easier and guarantee efficiency and productivity.

Of course, the new Premium Sliding Table Panel Saw also has all the proven Format-4 virtues and quality features. With these Format-4 system solutions, different outrigger versions and individual control variants, the kappa 590 sliding table panel saw makes perfection the norm!

Saw blade tilt +/-46°

Complex angle cuts as easy as possible – intuitive machine control with 15" touch screen

Highly efficient synchronous motor with continuously adjustable rotating speed

Preparation for automatic cutting optimization and network connection

3-axis scoring unit control with park position (optional)

Positioning control of the rip fence

Unlimited tool storage positions

Complete cutting sequences programmable

Possibility of importing cutting sequences

Additional functions: rabbets, grooving, notches, angle cuts, oblique cuts and false mitres

... FORMAT-4 Premium machines for premium requirements

- Constant high performance in continuous industrial operation

- Customer-specific optimized production solutions

- Solid design with premium components

- Wide range of configuration packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- CE + GS dust certified

- Tailor made financing solutions

Technical details

Effective working

Wagon length

3200 mm

Parallel guidance cut wedth

1250 mm

Details

Blade diameter

550 mm

Electric blade regulator (Optional)

check_circle

Electric scoring (Optional)

Automatic

Automatic parallel guidance

check_circle

Adjustable rotation speed

check_circle

Generals

Sizes*

3300x3940x1300 mm

Weight*

1200 kg

Total kW*

12

*Shown values may vary depending on the configuration of the machine.

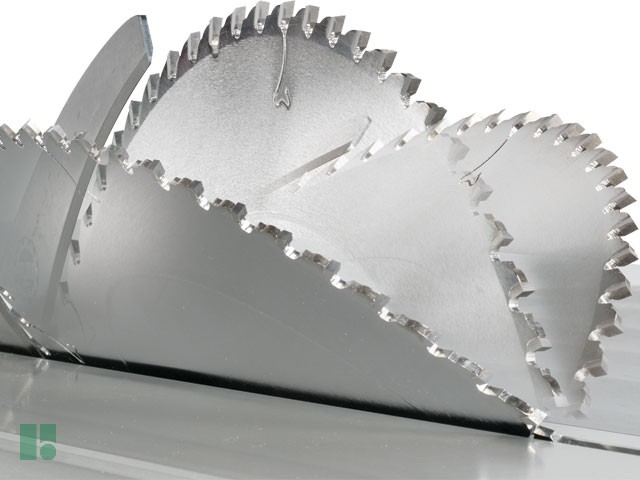

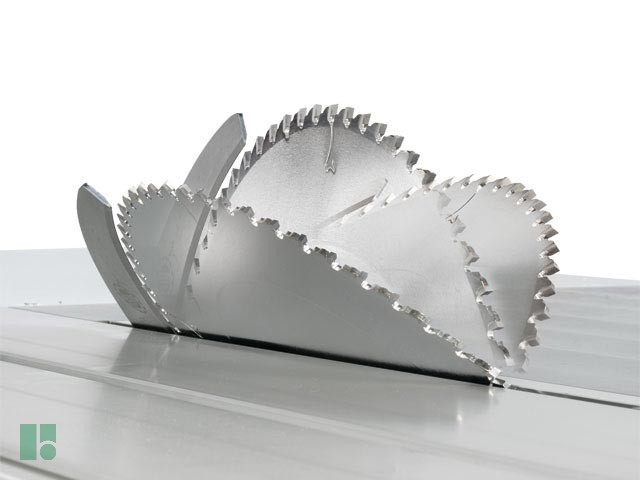

The new TOP circular saw unit 590

- Saw blade double pivoting +/-46°

- 3-axis “Control” scoring unit

- Scoring unit park position

- Sensational: saw blade change without tools

- Big cutting height: 202,0/140,8/118,7 mm (90°/+45°/-45°) – (optional at x-motion)

- Spraying unit for processing non-ferrous metals and plastics

- Tilt segment "Easy-Glide" for circular saw unit

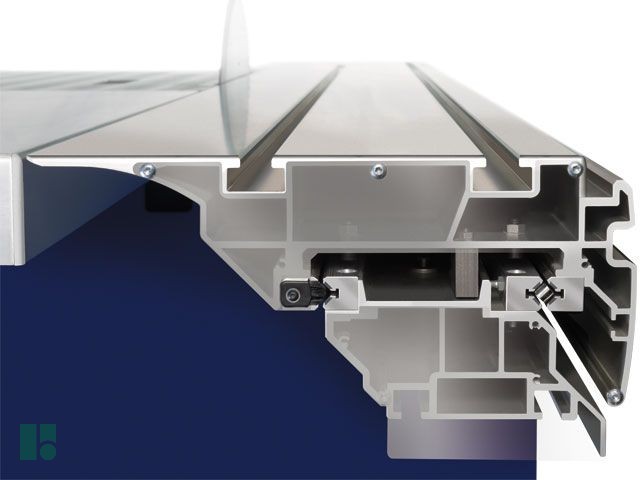

Synchronous motor with continuously adjustable speed control

"Easy-Glide" - 6 year guarantee!

- High precision double-sided trunnion support system

- High load-bearing capacity and operating life

- Play-free tilt

- Unaffected by dust

- Completely maintenance free

- No lubrication required

- 6 year guarantee

Big cutting height

Double pivoting of the circular saw blade +/- 46°

- Mitre cuts of frame parts with continuously overhead visible side

- Complex compound cuts

- Grooves in a miter

- and many more

"Easy-Lock" tool free saw blade change (Optional)

3-axis "Control" scoring unit (Optional)

Scoring unit park position

Safety made visible - Scoring unit operation display (Optional)

Simple, safe e quick - "Quick-Lock" saw blade clamping (Optional)

Intuitive "smartouch" control with 15" touch screen

Functions and cutting programs: rabbets, grooves, notches, angle cuts, oblique cuts plus, false mitres, compound cut plus, concealed V-neck, hip and valley rafters.

Standard fantastici

Electronic digital display can be read from every position

- Brightly illuminated red LED display facilitates the reading of values

- No batteries are required as it is directly connected to the machine’s power supply

- Recognises automatically whether the fence is in the vertical or horizontal position

- Measurement compensation of the saw blade tooth width

Rip fence with position control

- Optional with the x-motion

- Standard on the e-motion model

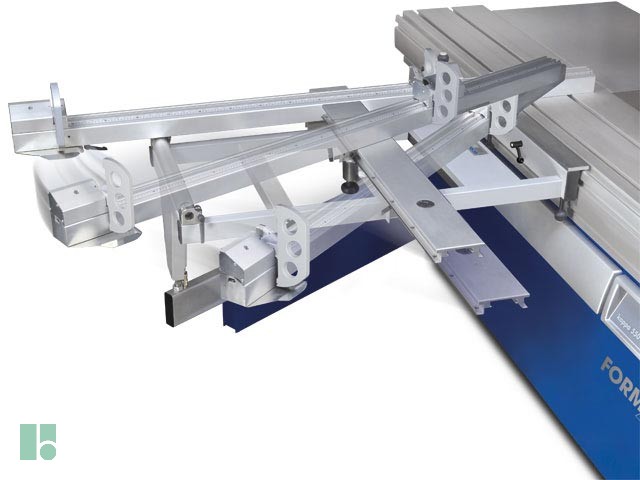

"X-Roll" sliding table, 10 year guarantee

Remote "ON" switch on Format sliding table (Optional)

Fix in every position - Multiple position locking of the sliding table

"X-Roll" outrigger table

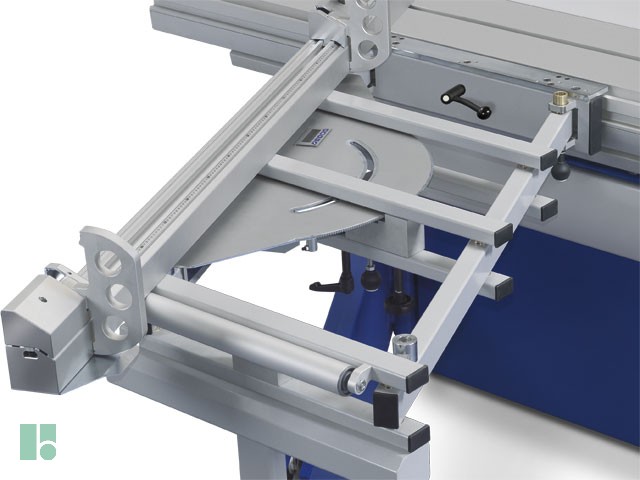

"Digi-compensation plus" - digital angle/length compensation (Optional)

Parallelogram outrigger table

Digital accuracy (Optional)

Telescopic crosscut fence

Even more flexible - Ergonomic locking lever at the crosscut fence

Parking the outrigger

Quick customizable overhead saw guard

Remote lock release

Overhead saw guard with sub-table extraction system

Pneumatic workpiece holder (Optional)

- Easy clamping of workpieces with maximum flexibility, can be used on all panel saws and spindle moulders that have a sliding table

- Easy set up due to magnetic fittings

- Safety cylinder ensures maximum working safety

- Pressure bar function is possible with every sliding table length

- Locking height 95 mm

- Clamping force approx. 300 kg

Always at hand e clearly visible - front tool compartment with LED (Optional)

Spraying equipment for the processing of non-ferrous metals and plastics (Optional)

Can now be retrofitted: Full surface support on the outrigger table

The crosscut fence

Rip fence for “X-Roll” sliding tables (Optional)

The electronic double mitre gauge (Optional)

Transport and mounting unit for outrigger table (Optional)

Related machineries

FIMAL CONCEPT 350-2.0

Circular saw blade c-tech

Electronic circular saw for ACM Composite Aluminum Panel Panel (Alucobond®, Dibond®), Fibrocement, Drywall, High Pressure Plastic Laminate (HPL), Aluminum Honeycomb (Alucore®, Larcore®, Plascore®) and Corian®

FIMAL CONCEPT 350-2.0

Circular saw blade c-tech

SPACE SAVING

The basic structure is machined with numerically controlled machine with only one positioning to ensure the planarity, squareness of all the measures. Concept it’s available in 3 versions, with different squaring lenghts: 2600 / 3200 / 3800 mm.

According the cutting lenght, Concept 350 takes 50% less space in comparison to a traditional circular saw.

Request infos

FELDER – c-tech kappa 590 x-motion