Panel height:

8 . 60 mm

Roll edge thickness:

0,4 - 3 mm

Edge in stripes thickness:

12 mm

CNC type:

CNC

Description

Edgebander tempora F1000

FELDER – FORMAT4 F1000

The dawn of a new era of Format4 edgebanders

The new Format4 tempora F1000 sets new standards in the field of comprehensive edge processing and combines exceptional durability, precision and efficiency to ensure maximum performance.

Thanks to its length, stability and large dimensioned machine frame, this machine ensures exceptionally smooth running of all units and guarantees the highest level of adjustment precision and maximum service life - even and especially when working in multi-shift operation.

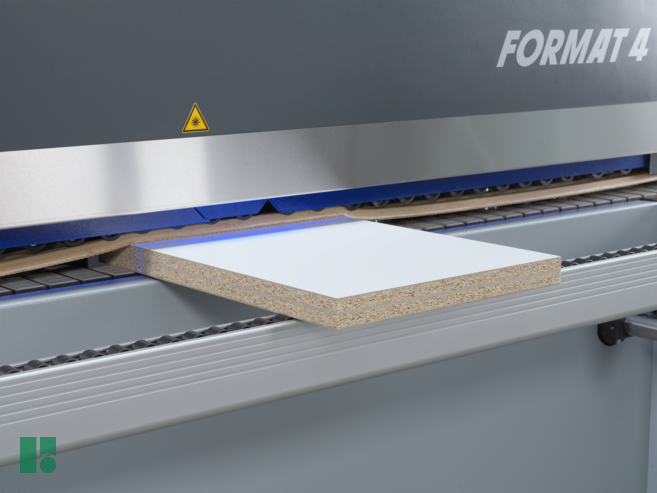

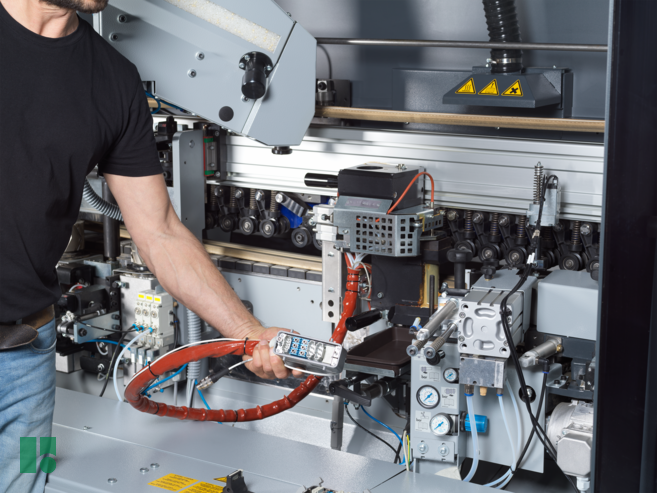

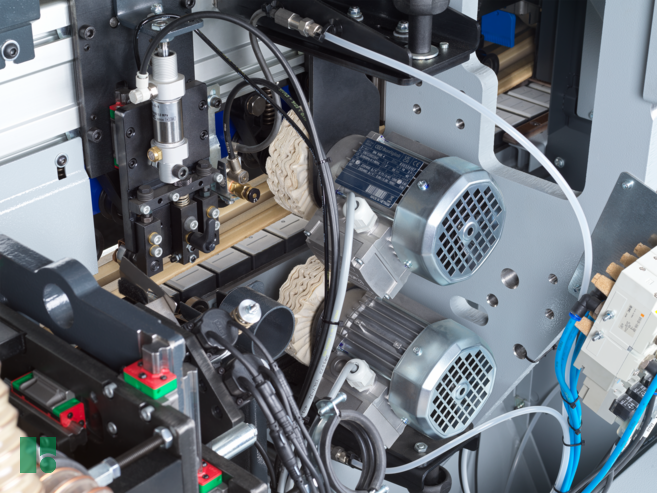

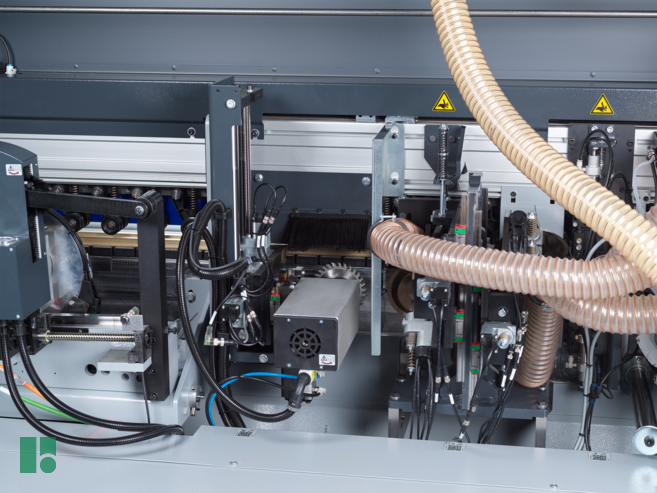

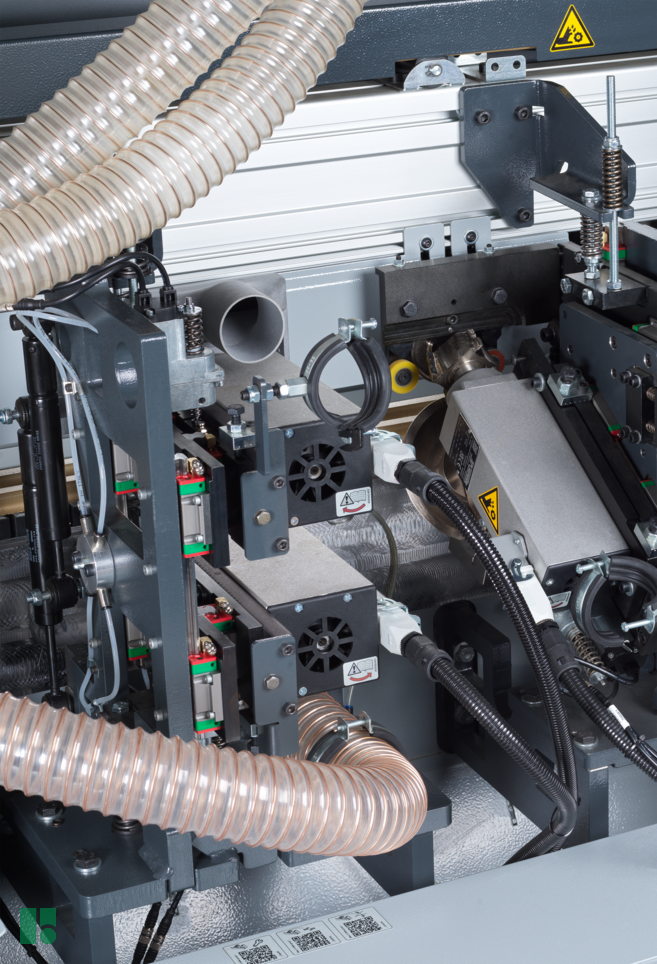

The F1000 is equipped with a belt feed drive on the upper pressure bar to ensure careful material handling of surface-sensitive materials. Compared to a pressure roller infeed, the belt feed drive provides uniform pressure distribution over the entire length of the workpiece, guaranteeing more precise machining results and minimizing cleaning effort by eliminating abrasion and dust.

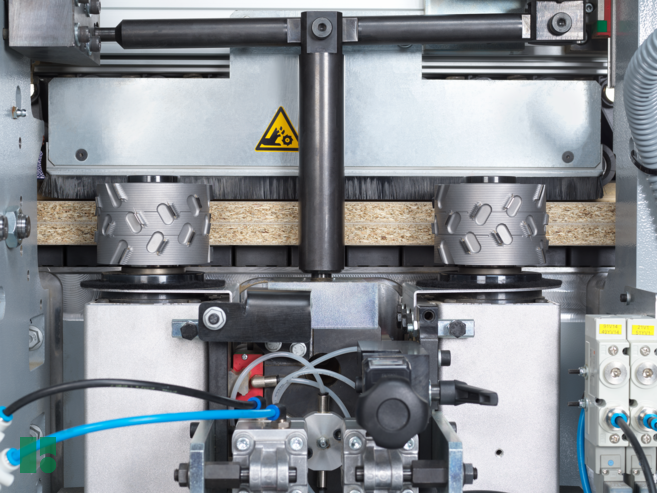

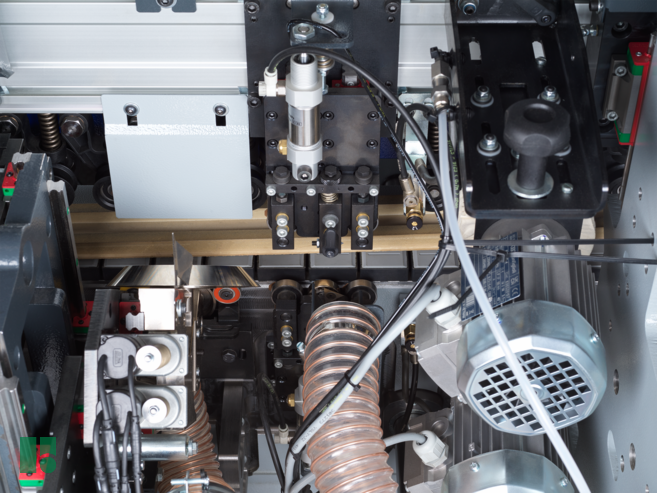

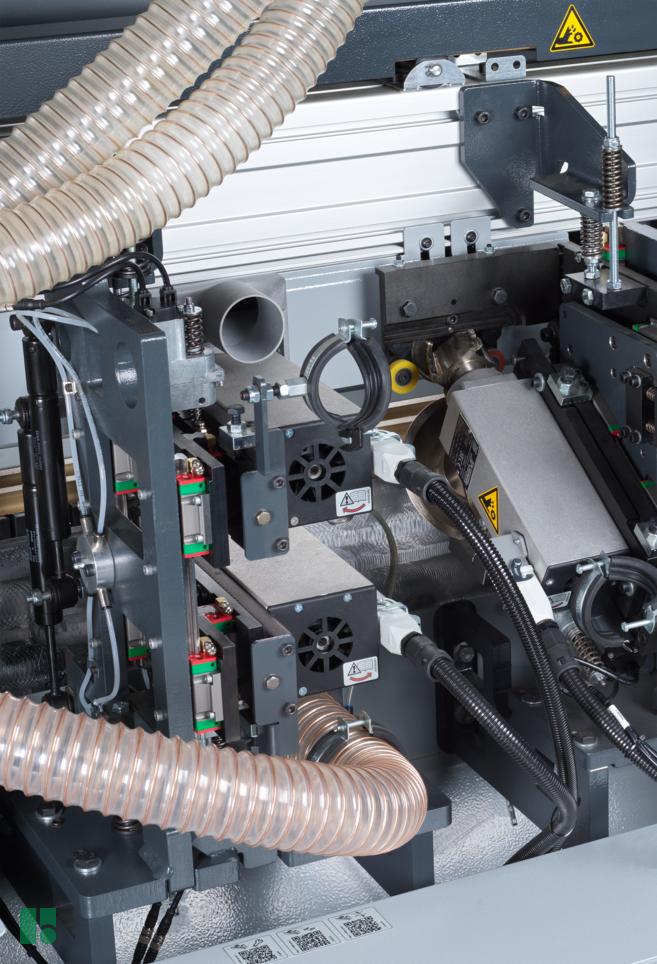

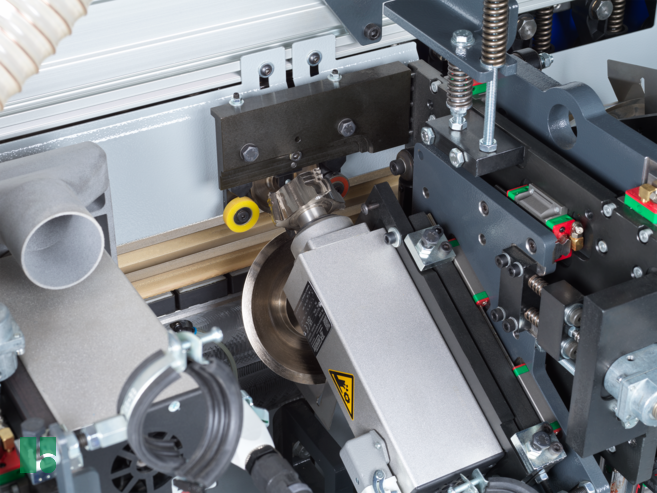

The edge jointing unit impresses with its powerful motors and automatic, centric adjustment to the workpiece height, which prevents one-sided wear and significantly extends the service life of the router. The top-mounted glue pot ensures faster heat-up and the integrated drain function makes cleaning much easier.

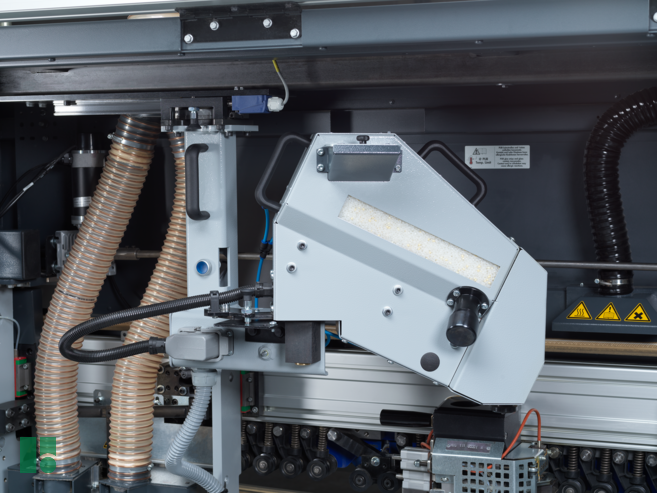

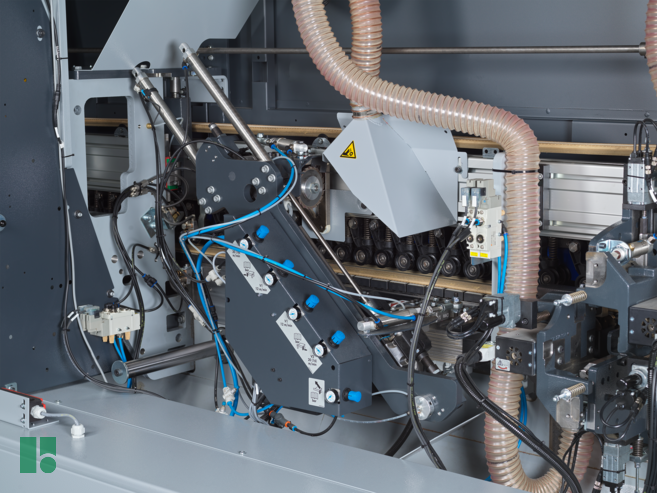

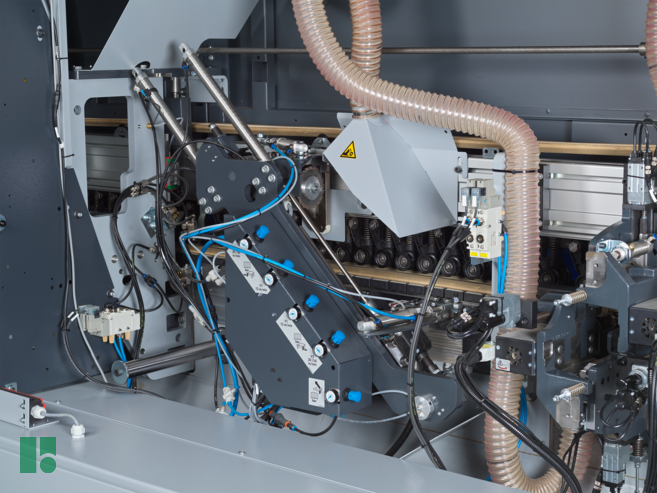

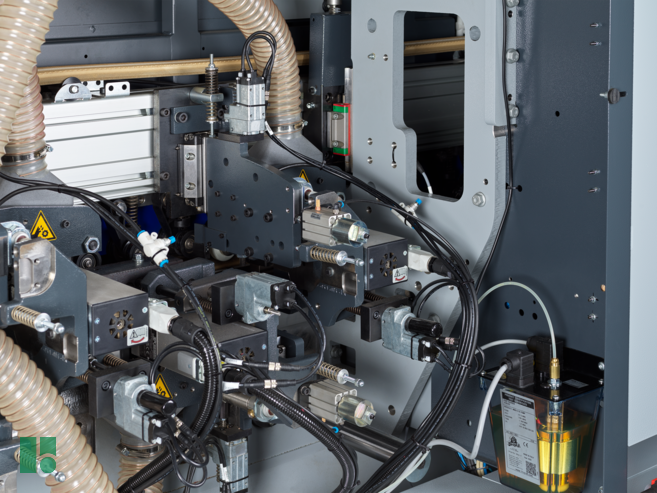

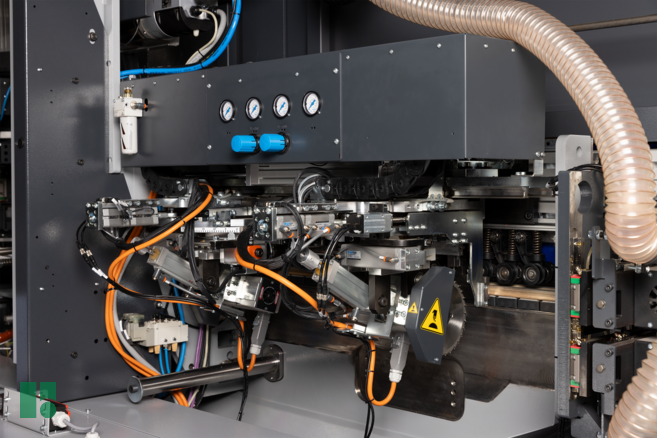

The all-new, completely redesigned corner rounding unit with CNC-controlled positioning axes delivers even more precise results, minimizes maintenance and increases efficiency. The patented multi-radius router cutters ensure a uniform edge radius even when processing thin edges.

The F1000 equipment packages Classic, Professional and Performance offer targeted customization to meet your individual operational requirements. Opt now for a Format4 machine – You will be impressed!

Classic:

Installation length 8000 mm

Edge thickness 0,4 - 12 mm

Workpiece height: 8 - 60 mm

Feed speed: 12 - 20 m/min

Top-mounted application-controlled glue pot

Automation e-motion

Corner rounding unit (CNC controlled)

Complete edge processing

Top pressure belt

Premilling unit "classic"

Multifunction trimming "classic"

Radius scraping unit "classic"

Professional:

Installation length 8000 mm

Edge thickness 0,4 - 12 mm

Workpiece height: 8 - 60 mm

Feed speed: 12 - 20 m/min

Top-mounted application-controlled glue pot

Automation e-motion

Corner rounding unit (CNC controlled)

Complete edge processing

Top pressure belt

End trimming unit 45°

Premilling unit "professional"

Multifunction trimming "professional"

Radius scraping unit "professional"

Performance:

Installation length 8000 mm

Edge thickness 0,4 - 12 mm

Workpiece height: 8 - 60 mm

Feed speed: 12 - 20 m/min

Top-mounted application-controlled glue pot

Automation e-motion

Corner rounding unit (CNC controlled)

Complete edge processing

Top pressure belt

Premilling unit "professional"

Multifunction trimming "professional"

Radius scraping unit "professional"

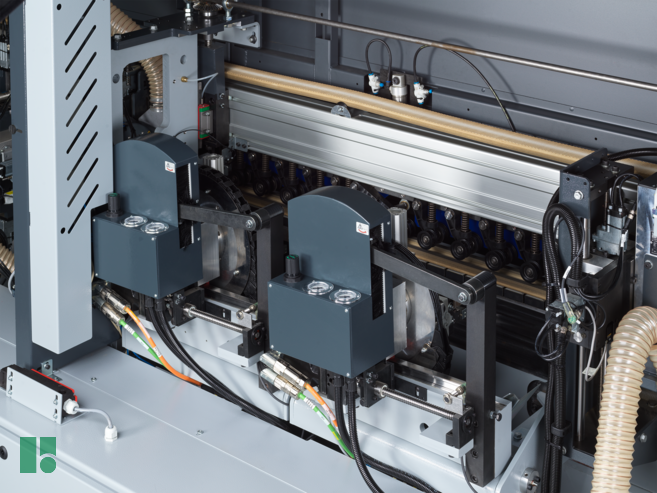

twin-motor linear end trimming unit

Technical details

Effective working

Panel height

8 . 60 mm

Details

Roll edge thickness

0,4 - 3 mm

Edge in stripes thickness

12 mm

Edge in stripes

check_circle

Towing type

Chain

Interchangeable glue tank

check_circle

Software/C.N.

CNC type

CNC

*Shown values may vary depending on the configuration of the machine.

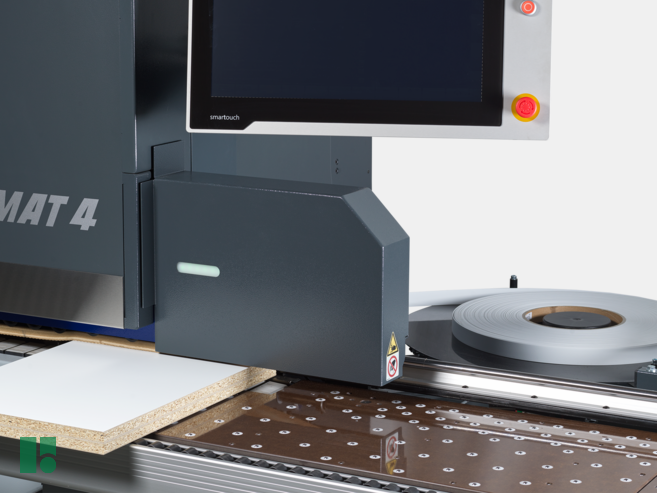

18" smartouch control system with e-motion

Unlimited memory for user-defined edge programs

Maintenance plan, linear meter counter

Simple, self-explanatory representation of all units and functions

Selection of the units and precise fine adjustment of the motorized positioning-controlled units (adjustment accuracy 1/100 mm (0.0003 in)) directly from the control panel

Glue temperature setting and automatic temperature reduction of the glue whilst in standby mode

Upper pressure bar incl. belt feed drive e-motion

Chain feed with 12 - 20 m/min or 12 - 25 m/min

Workpiece Feed and infeed Guide e-motion

Air cushion table for easy and gentle material handling

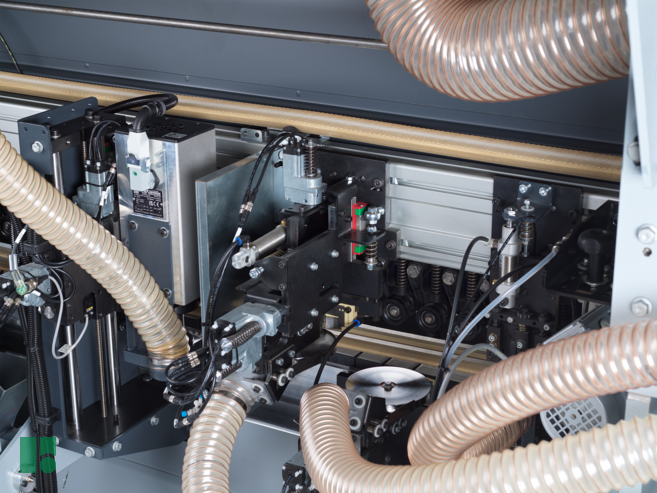

Centric Edge jointing unit

Top-mounted, controlled glue pot incl. cleaning function

Premelter EVA for adhesive granulate, capacity 3,5 kg

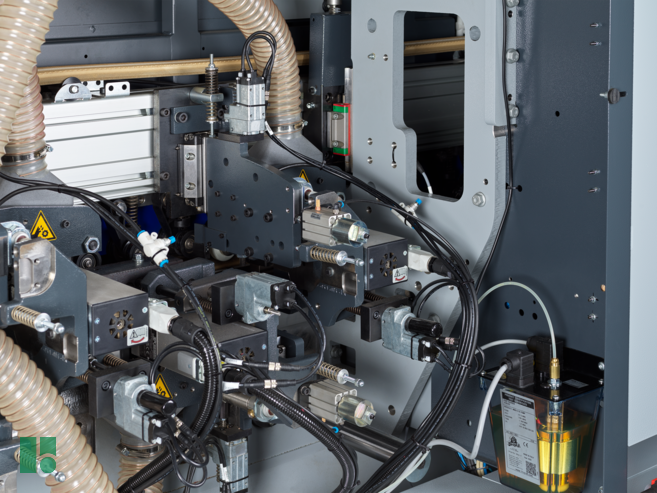

Application controlled pneumatic pressure unit e-motion with 4 pressure rollers

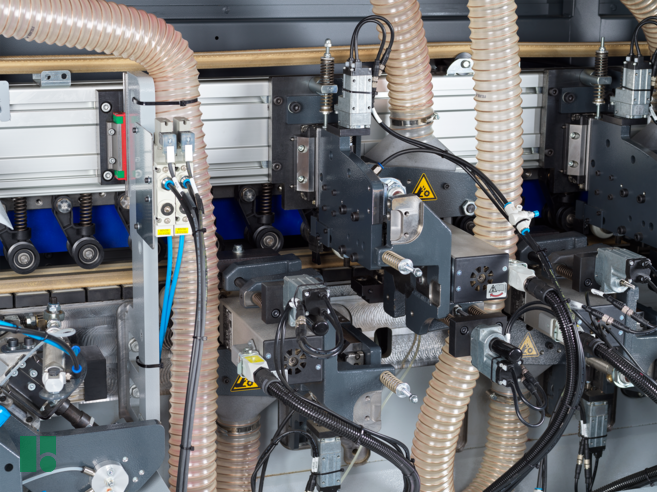

2-motor corner rounding unit

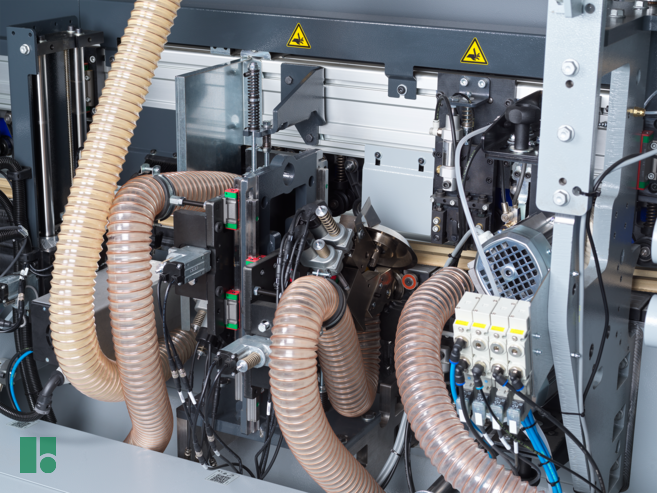

Glue scraping unit, pneumatically controlled

Buffing unit with 2 motors

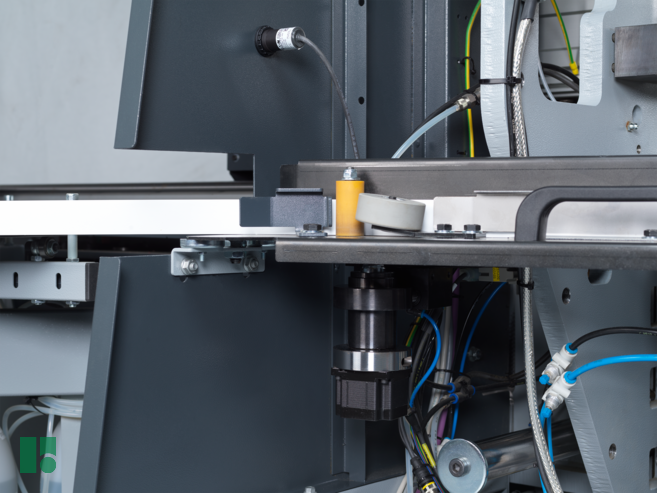

edgeControl: edge and workpiece measurement with bluetooth (option)

The values for edge and workpiece thickness, that are recorded to the hundredth of a millimeter with the wireless measuring unit, are transferred to the machine's smartouch operating unit via Bluetooth. The controller recognises the measured values and sorts them automatically according to workpiece or edge thickness. The operator then selects the desired setting values from the measurement data log that contains the five last measured values. Smartouch automatically calibrates all required units to the exact dimensions.

With edgeControl, production losses due to typing or measuring errors as well as tolerance deviations of the edge dimensions are eliminated.

Additional workpiece support for floor mounting incl. swivel arm (option)

Mitre fence for narrow parts (optional)

Magazine for strip material with a capacity of 144 mm (optional)

Automatic edge feeder incl. motorized clamp (option)

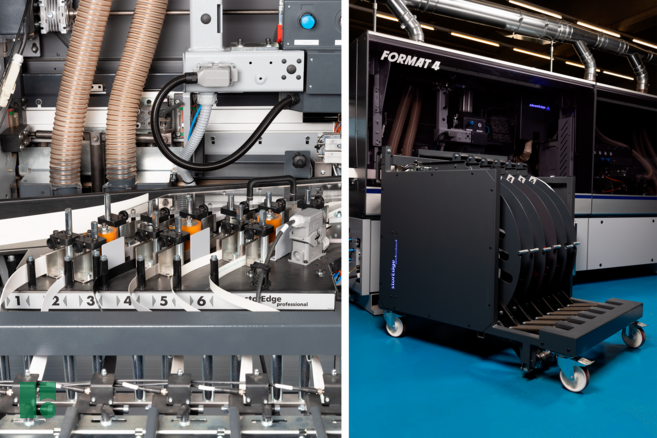

Edge magazine "storeEdge professional" for 6 coiled edge material rolls (option)

Premelter PUR 2 kg cartridges or granulate (option)

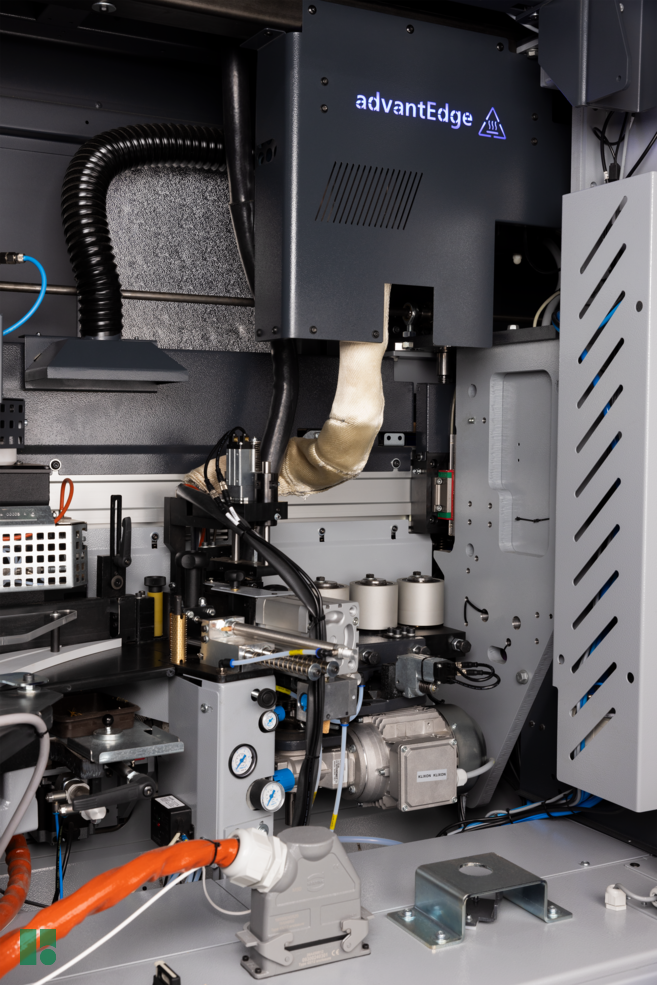

Format4 advanteEdge for a visual zero joint (option)

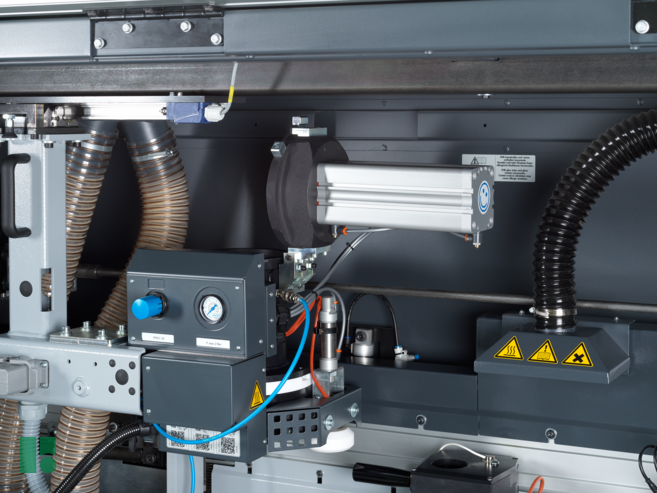

Grooving unit for horizontal or vertical processing (option)

Hot air blow dryer at the machine outfeed (option)

SET sprayng units (option)

Releasing agent spraying unit

Cleaning agent spraying unit

Antistatic agent spraying unit

Lubrication spraying unit

Variable feed speed in steps of 1 m/min for 12-20 m/min (option)

F1000 - Premilling unit "classic" for a 45° bevel and flush trimming (option)

F1000 - e-motion end trimming saw unit with45° traverse angle and 2 motors

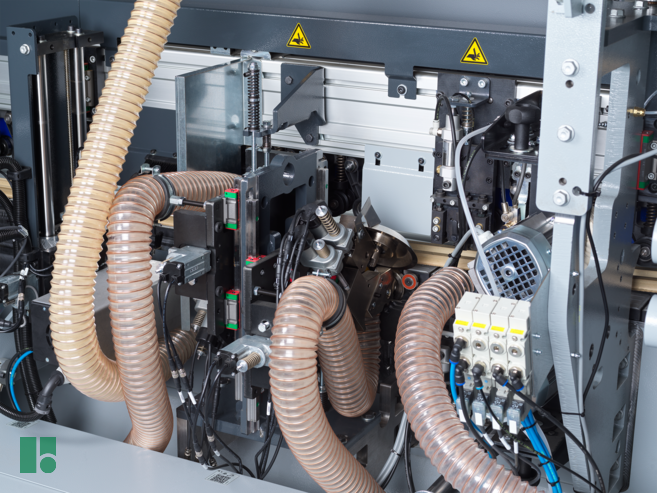

F1000 - Multifunction trimming unit e-motion "classic"

F1000 - Radius scraping unit "classic" e-motion

F1000 - SET nesting package F1000 performance (option)

Nesting function for the scraper unit pneumatically operation-controlled

Nesting function for the multifunction trimming unit "classic"

Nesting function for the radius scraping unit "classic"

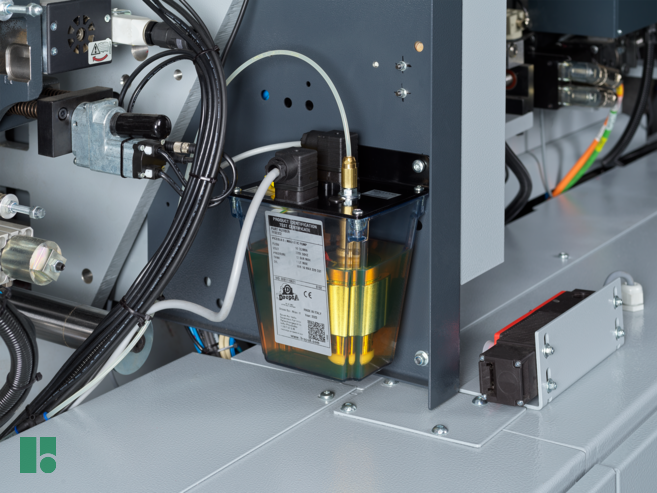

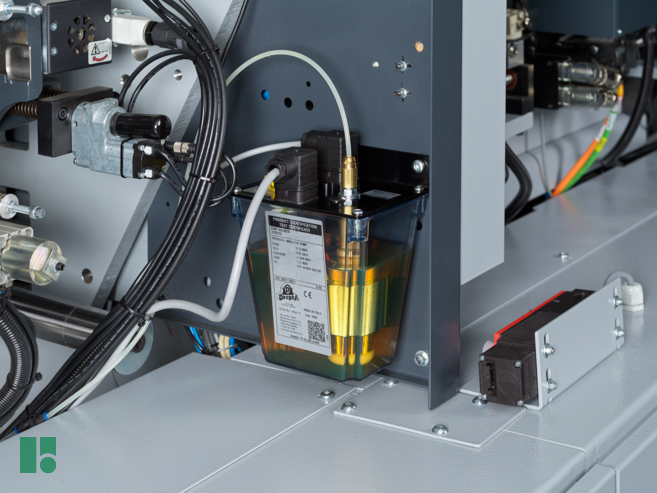

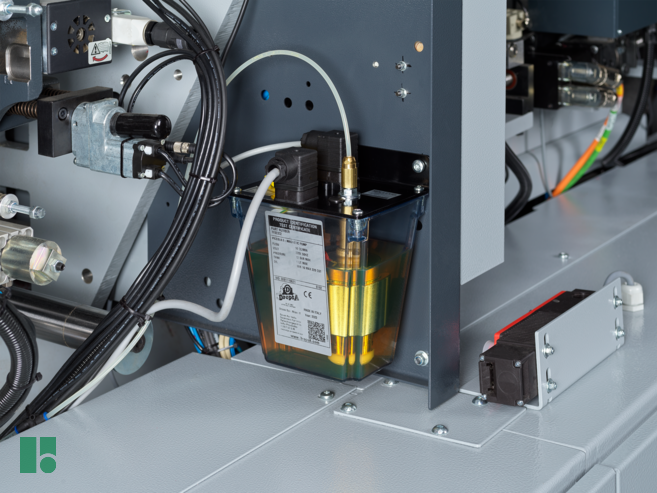

F1000 - Automatic central lubrication of the units (option)

Automatic central lubrication ensures accurate and controlled lubrication of the guiding systems of the units. The lubricant is automatically applied following a preset time interval, ensuring a constant supply and trouble-free operation of the units.

F1000 - PROFESSIONAL - e-motion end trimming saw unit with45° traverse angle and 2 motors

F1000 - PROFESSIONAL - Premilling unit "professional"

F1000 - PROFESSIONAL - Multifunction trimming unit "professional" e-motion

F1000 - PROFESSIONAL - Multiradius scraper unit "professional" e-motion

F1000 - PROFESSIONAL - SET nesting package F1000 professional (option)

Nesting function for the scraper unit pneumatically operation-controlled

Nesting function for the premilling unit "professional"

Nesting function for the multifunction trimming unit "professional"

Nesting function for the multiradius scraper unit "professional"

F1000 - PROFESSIONAL - Automatic central lubrication of the units (option)

F1000 - PERFORMANCE - Twin-motor linear end trimming unite-motion

F1000 - PERFORMANCE - Premilling unit "professional"

F1000 - PERFORMANCE - Multifunction trimming unit "professional" e-motion

F1000 - PERFORMANCE - Multiradius scraper unit "professional" e-motion

F1000 - PERFORMANCE - Automatic central lubrication of the units

SET nesting package F1000 performance (option)

Nesting function for the scraper unit pneumatically operation-controlled

Nesting function for the premilling unit "professional"

Nesting function for the multifunction trimming unit "professional"

Nesting function for the multiradius scraper unit "professional"

F1000 - PERFORMANCE - Variable feed speed in steps of 1 m/min for 12-25 m/min (option)

Related machineries

FELDER - FORMAT4 tempora F800 60.12 e-motion

Edgebander

Edgebander

FELDER - FORMAT4 tempora F800 60.12 e-motion

Edgebander

Saving you time is our motivation

Time, the most important resource in a modern workshop was one of the main focuses whilst developing the new tempora machine concept. Processing edges needs to be as quick, easy and efficient as possible. To achieve this, the tempora model combines the key characteristics of speed, productivity, flexibility and user comfort in a convincing com...

FELDER G 330

Edgebander

With the G 330 Edgebander, Felder offers you a perfect, professional solution for small workshops with smaller investment options.

The Felder G 330 meets the challenge of the increasing quality demands in the “compact class”. Precise edge gluing without the need for further manual finishing, is the most convincing element of the most recent Felder development. The G 330 se...

FELDER G 363 - G363R

Edgebander

Performance, flexibility and user comfort all in one!

Compact design, reliable, high-quality mechanical engineering - perfect machining results.

The new Felder edgebanders G 363, G 363R and G 383 with robust chain conveyors and application-controlled premilling unit in the standard version impress with their performance, flexibility and ease of use at the bes...

FELDER - FORMAT4 tempora 60.06 L glueBox

Edgebander

Edgebander tempora F600 60.06L glueBox

FELDER - FORMAT4 tempora 60.06 L glueBox

Edgebander

Format4 tempora F600 with glueBox: PUR-edge banding without glue pot.

Revolutionarily simple, clean and economically highly profitable.

Edgebanding needs to be as quick, easy and efficient as possible. To achieve this, the Format4 tempora models combine the core competences of speed, productivity, flexibility and ease of use in a convincing overall...

Request infos

FELDER – FORMAT4 F1000