—

LARI e LARI

FR300 TA TB 3F

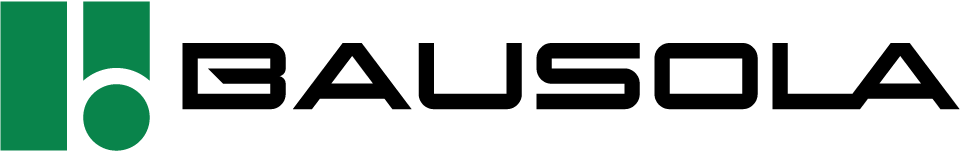

Numerically controlled machining center for processing wooden window and door frames, complete with anuba boring head and mortising head

Code: 1432

restore Production year: 2005 error_outline Status: Discreet

domain Availability: In stock check_circle EC legislation: Compliant

Controlled axes number:

3

Chisel mortising machine units

Arms number:

3

Description

Numerically controlled machining center for processing wooden window and door frames, complete with anuba boring head and mortising head

LARI e LARI FR300 TA TB 3F

Machining center for milling, anubing and plastering on wooden elements or plastic and composite materials.

Structure in stabilized steel tubing. Sliding on cemented and ground guides with recirculating ball slides.

Axis movements with racks and ball screws.

Linear, circular, helical, spline interpolation. Point programming.

N. 3 interpolated axes (X - Y - Z)

Worktop 4000 x 500 mm

Vertical electrospindle with HSK 63F connection complete with C axis

3.3 kW horizontal electrospindle with ER32 connection

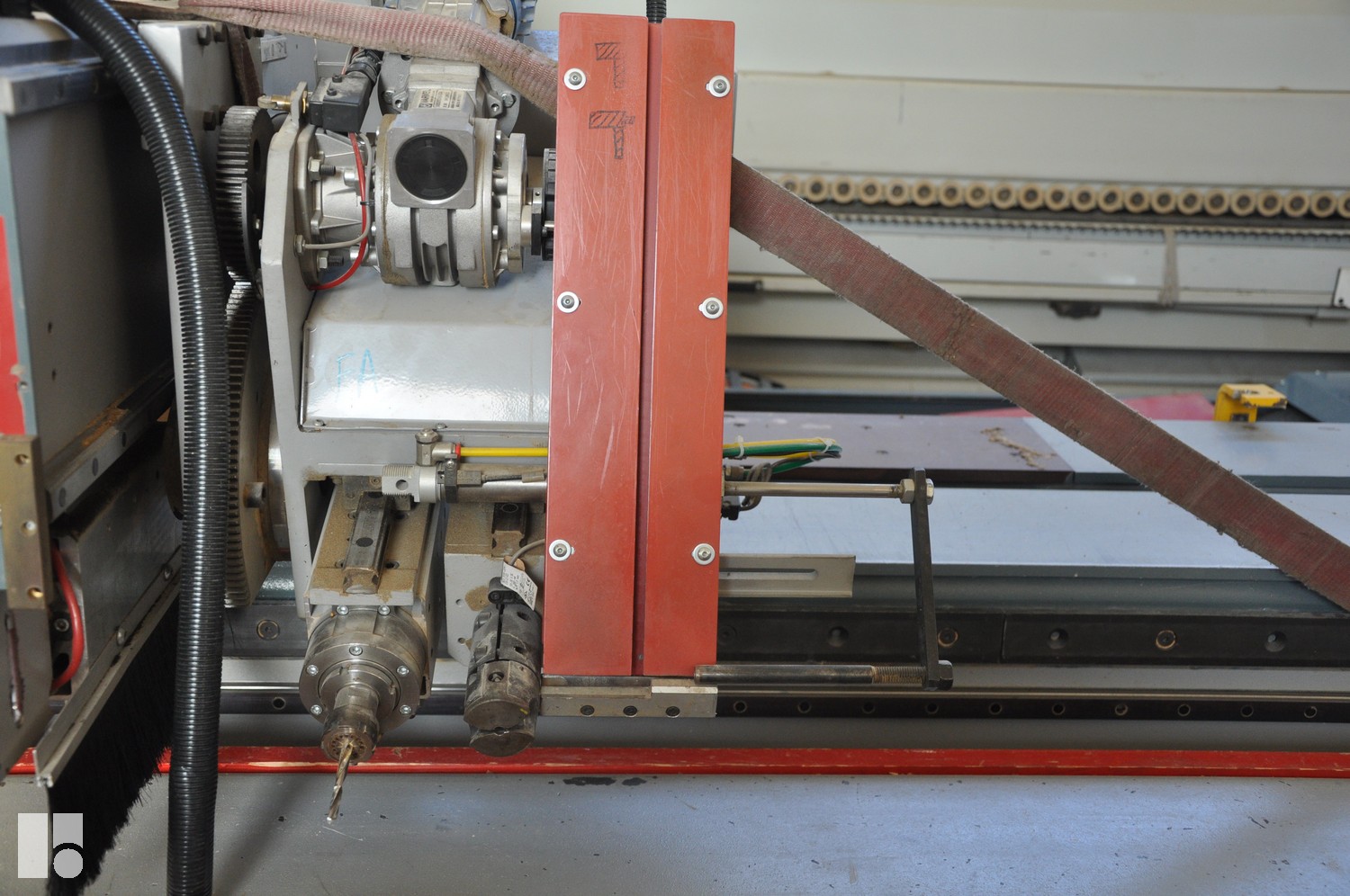

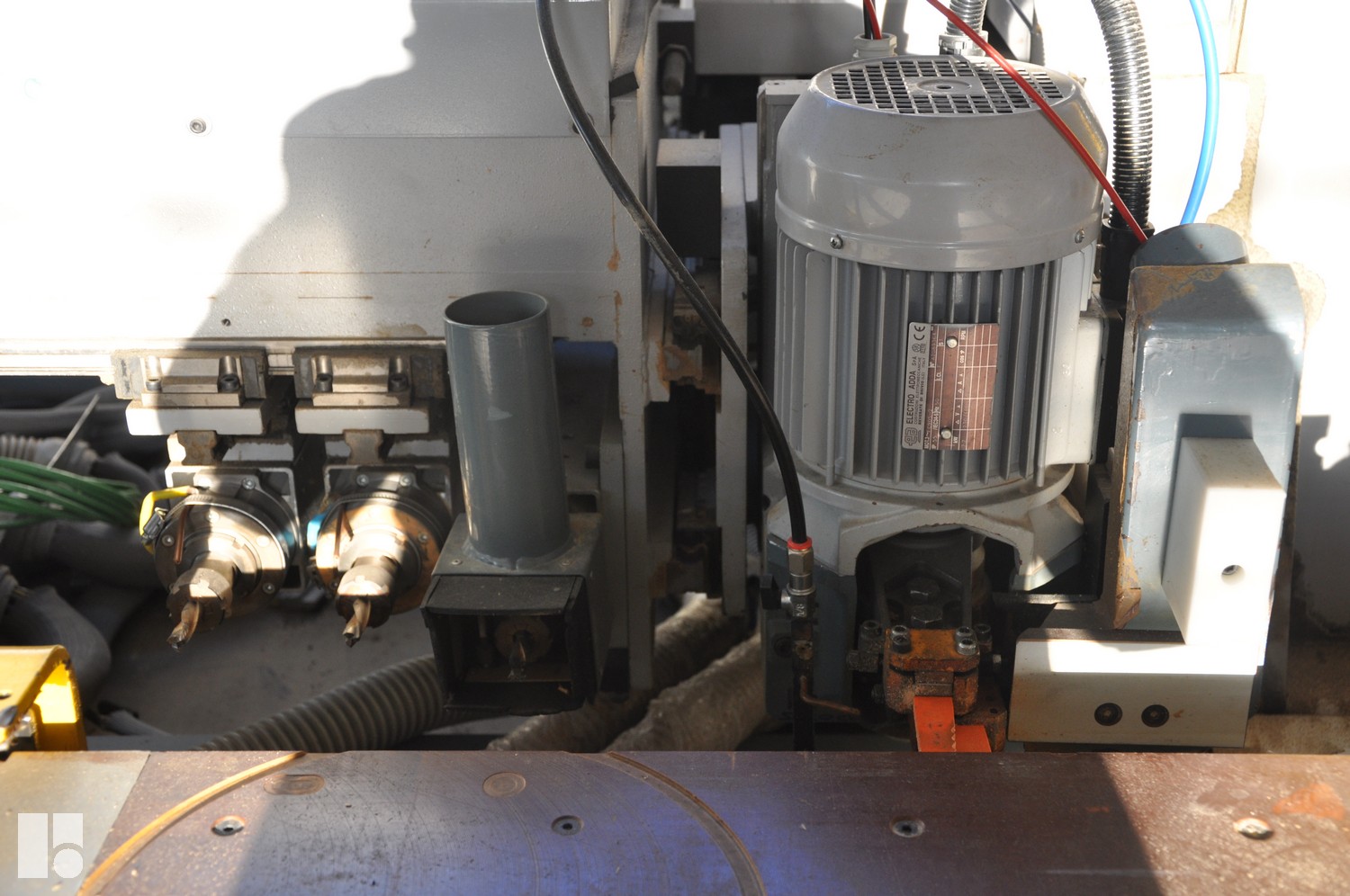

Mortising head

Head for drilling and screwing Anuba type hinges

Shutter milling group with 3 electrospindles with variable center distance, 2.2 kW each

N. 3 Arms complete with N. 6 suction cups

Parking arms outside the work surface

100 m3/h vacuum pump

4 retractable front stops

Vertical locking bar in chisel with automatic overturning during milling and anubing

Automatic tool change from tool magazine

Technical details

Effective working

Effective X

3200 mm

Eeffective Y

1300 mm

Effective Z

100 mm

Details

Heads number

1

Controlled axes number

3

Main motor power

7,5 kW

Mils connection drive motor

HSK 63F

Horizontal motors (Optional)

check_circle

Anuba hinge unit

check_circle

Chisel mortising machine units

check_circle

Arms number

3

Suction quantity

6

Grips number (Optional)

4

Security

Cabin

Vacuum pump

1 x 100 mc/h

Software/C.N.

Software

Customized

Generals

Sizes*

6000x4500x2300 mm

Weight*

4500 kg

Total kW*

18

*Shown values may vary depending on the configuration of the machine.

Related machineries

FELDER - FORMAT4 profit H22 XYLMAC

CNC / Pantographs

Machining center for windows and doors

FELDER - FORMAT4 profit H22 XYLMAC

CNC / Pantographs

The base of the H22 profit machining center is made up of high-thickness, electrically welded tubular sections.

X-axis guide system:

The X-axis arm is driven by a rack with inclined and curved teeth.

Y-axis guide system:

The Y axis is positioned with a ground ball screw.

Z axis sliding system:

The Z ...

FELDER - FORMAT4 Profit H200 13.33

CNC / Pantographs

Work center for windows and doors

FELDER - FORMAT4 Profit H200 13.33

CNC / Pantographs

UPS - Computer Power Supply Safety System

Optical Machine Status Indicator - Different colors indicate the machine status

Blue LED lighting strip, integrated into the front mount of the stand

6 workpiece supports with rows of stops at the front and rear

4 insertion devices with rows of stop pins at the front and rear

Hoseless dual-circuit vacuum system wi...

LARI e LARI FR20 TA TB

CNC / Pantographs

Milling, chiesel and anuba work centre

LARI e LARI FR20 TA TB

CNC / Pantographs

Movement axes with racks and screws recirculating spheres.

Industrial numerical control.

Windows XP system.

TFT 12"s Color Video"

Linear, circular, helical, spline interpolation.

Parameter programming using pre-set macros.

Machine composition:

Electro spindle 3.4 kW at 18,000 rpm

ER32 staple attack

3 interpolated axes

Engine with tilt control...

MARZANI MULTICENTER 300 2F

CNC / Pantographs

Work center for windows and doors

MARZANI MULTICENTER 300 2F

CNC / Pantographs

Machine provided with a steel skeleton with sliding guides on tracks and ball sliding blocks.

Axes movement by means of ball screws controlled by C.C. motors and decimal resolution Encoder.

Machine tasks controlled by a personal computer with Windows 10

Linear and circular interpolation on each milling axis.

Machine made of:

Horizontal milling tool with kW 3,3 high-f...

Request infos

LARI e LARI FR300 TA TB 3F