—

FELDER - FORMAT4

tempora 60.06 L glueBox

Edgebander tempora F600 60.06L glueBox

Panel height:

8 - 60 mm

Roll edge thickness:

0,4 - 3 mm

Edge in stripes thickness:

6 mm

Glue type:

PUT

Description

Edgebander tempora F600 60.06L glueBox

FELDER – FORMAT4 tempora 60.06 L glueBox

Format4 tempora F600 with glueBox: PUR-edge banding without glue pot.

Revolutionarily simple, clean and economically highly profitable.

Edgebanding needs to be as quick, easy and efficient as possible. To achieve this, the Format4 tempora models combine the core competences of speed, productivity, flexibility and ease of use in a convincing overall package. The final finishing results when processing both coiled and strip material convince with incredibly high standards.

Modern and optimised edge processing aggregates and a flexible machine body guarantees absolute stability and reliability even at the highest of processing speeds. The user friendly control options, x-motion plus and "m-motion" ensure absolute repeatability and individual configurable operating programs enable quick manual change of the aggregates as well as control via the smartouch control panel.

The Format4 tempora 60.06 L has a single or dual motor corner rounding unit with a workpiece height of up to 60 mm.

The patented "advantEdge" brings "invisible joints" to your workshop. You can equip your tempora individually with a single or twin-engine corner rounding unit and your desired finishing units on three unit spaces. The intuitive control unit smartouch with 10"or 16" touchscreen ensures maximum operating comfort and highest productivity.

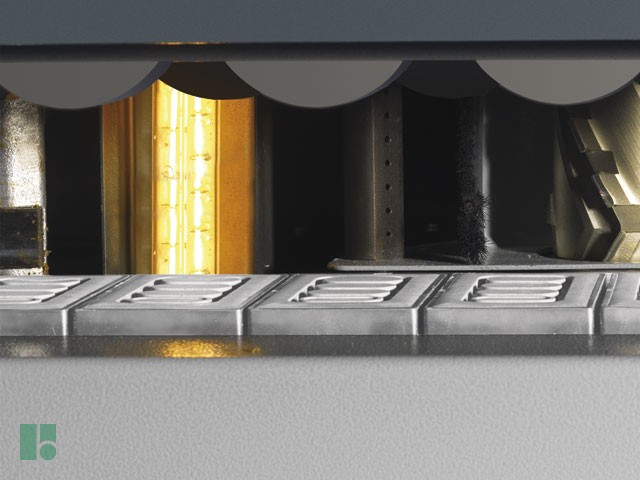

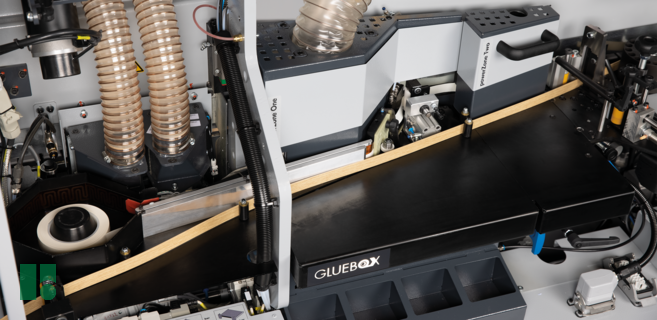

The revolutionary

glueBox

makes PUR glue processing easier and more convenient than ever before. Heat and water resistance, a very small glue joint as well as reduced glue consumption - all advantages of the PUR-glue can be used uncompromisingly with the glueBox. The PUR drawbacks such as complicated processing, dirty and hardened glue pots, annoying cleaning as well as the complex storage are a thing of the past with glueBox. Instead of the PUR adhesive in the glue pot of edge banding machines, a thin PUR adhesive strip in the glueBox is fused almost invisibly between the edge material and the workpiece. Taking all costs into account (investment, adhesive material consumption and cleaning costs/expenditure), in the effective field of application the glueBox saves approx. 70% in comparison to conventional PUR granulate processing.

glueBox - PUR edge banding without glue pot

The glueBox attaches a thin PUR tape between the edge and the workpiece and fuses the two components together almost invisibly. Through heat activation of the glue perfect adhesion is achieved.

Fast: Ready to use in only 90 seconds

Flexibility: Available in 2 coiled lengths of 25 and 100 meters and in 4 heights of 16, 19, 28 and 40 millimeters

Comfort: Tool free PUR tape replacement

Efficiency: Almost immediate switching to conventional glue pot for EVA glue and vise versa

Technical details

Effective working

Panel height

8 - 60 mm

Panel minimum width

70 mm

Details

Roll edge thickness

0,4 - 3 mm

Edge in stripes thickness

6 mm

Edge in stripes

check_circle

Towing type

Chain

Premilling unit (Optional)

Pneumatic

Glue type

PUT

Shear

check_circle

Infrared lamp

check_circle

Edge trimming unit

Gleam

Rounding knives/shrub shears unit

Automatic

Rounding unit (Optional)

Automatic

Radius scraping unit (Optional)

Automatic

Joint scraping unit (Optional)

Automatic

Cleaning liquid (Optional)

check_circle

Software/C.N.

CNC type

Numerical Control

Generals

Sizes*

4412x1511x1468 mm

Weight*

2600 kg

Total kW*

10

*Shown values may vary depending on the configuration of the machine.

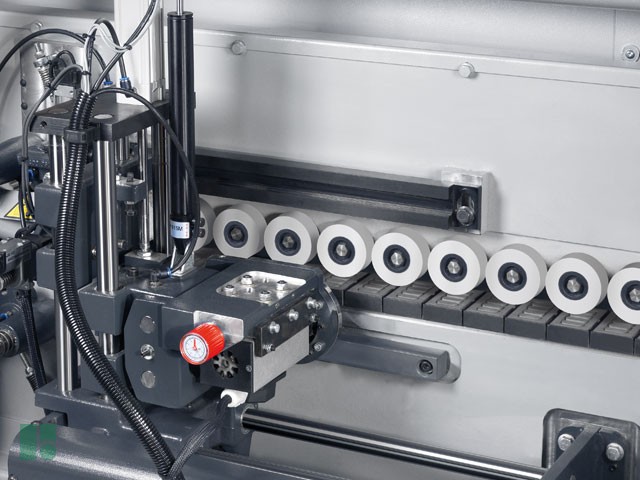

Pressure beam

On x-motion plus, a motorised pressure beam moves to the desired workpiece thickness

Format-4 storEdge including support

Format-4 storEdge

Save twice the space

Infeed fence

Air cushion table for easy and gentle material handling

Smartouch control unit with m-motion

Storage and loading of user-defined working programs

Selection of the motor-position controlled aggregates

Fine-adjustment of the aggregates in the range of 1/100th of a millimetre

Intuitive adjustable and self-explanatory display of the aggregates

Setting of the glue parameters (EVA or PUR)

Order specific selection of the aggregates

Fine-adjustment of the distance parameters

Maintenance plan, clear text error messages, odometer for total metres of material used

Smartouch control unit x-motion PLUS

Unlimited memory for user-defined edge programs

Maintenance plan, odometer for total metres of material used

Simple, self-explanatory representation of the units and their functions

Aggregate selection, exact fine adjustment of the motor positionable aggregates (accuracy of up to 1/100 mm) all from the main control panel

Glue temperature setting and automatic temperature reduction of the glue whilst in standby mode Now available with a monitor size of 10.4" and 15"

EdgeControl: edge and workpiece measurement with bluetooth

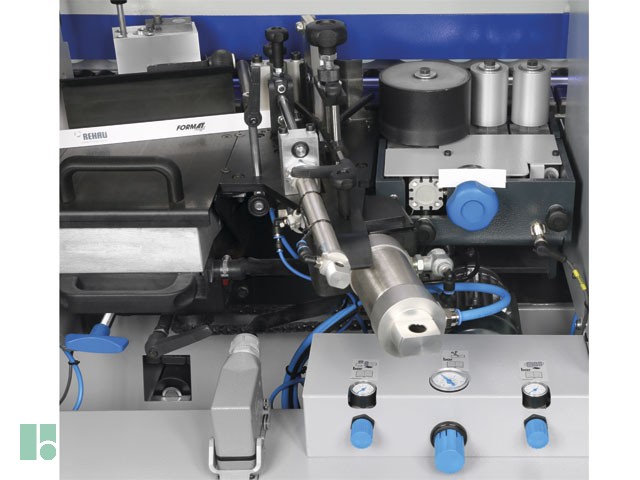

Premilling unit - ensures a perfect "finish"

Infrared lamp - for an improved edge adhesion when processing cold workpieces

Edge feed

Pressure zone - pratically invisible glue-joint

End trimming unit - precise cuts for every application

Multi-functional trimming unit - innovative precision with quick setup

"Nesting" Package

Corner rounding unit an indispensable option

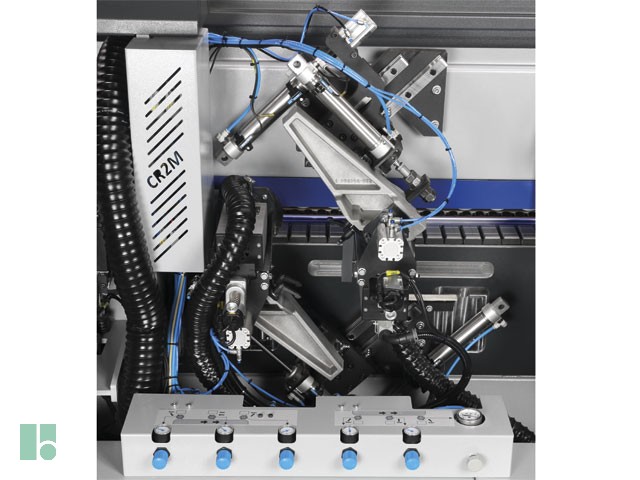

Two motor double corner rounding unit

Radius scraping unit

Electronically controlled glue scraping unit

Sparyng equipment for the perfect "finish", leaving a workpiece requiring no further processing

Buffering unit

puReady: nitrogen box for glue pots with PUR adhesive

Delays reaction processes in the PUR adhesive and thus prolongs the processing time

Increases flexibility when using different PUR colours and PUR adhesives

Provides space for the storage of two glue pots

Simple operation and clear control displays

Mobile and space saving without power- and compressed air connection

Compatible with all glue pots of the tempora edge banders F600 / F800

glueBox - PUR edge banding without glue pot

Fast: Ready to use in only 90 seconds

Flexibility: Available in 2 coiled lengths of 25 and 100 meters and in 4 heights of 16, 19, 28 and 40 millimeters

Comfort: Tool free PUR tape replacement

Efficiency: Almost immediate switching to conventional glue pot for EVA glue and vise versa

Related machineries

FELDER - FORMAT4 tempora F800 60.12 e-motion

Edgebander

Edgebander

FELDER - FORMAT4 tempora F800 60.12 e-motion

Edgebander

Saving you time is our motivation

Time, the most important resource in a modern workshop was one of the main focuses whilst developing the new tempora machine concept. Processing edges needs to be as quick, easy and efficient as possible. To achieve this, the tempora model combines the key characteristics of speed, productivity, flexibility and user comfort in a convincing com...

FELDER - FORMAT4 puReady

Edgebander

Nitrogen box for glue pots

FELDER - FORMAT4 puReady

Edgebander

The puReady nitrogen box makes you flexible in the use of PUR adhesives. In the future you can stay relaxed during production breaks, colour or glue changes. With puReady, your PUR adhesive, stored in nitrogen, remains fresh and processable for a long time. This keeps you flexible in edgebanding and also facilitates the cleaning of the glue pots.

- Delays reaction processes in th...

FELDER G 330

Edgebander

With the G 330 Edgebander, Felder offers you a perfect, professional solution for small workshops with smaller investment options.

The Felder G 330 meets the challenge of the increasing quality demands in the “compact class”. Precise edge gluing without the need for further manual finishing, is the most convincing element of the most recent Felder development. The G 330 se...

FELDER - FORMAT4 tempora F600 60.06L

Edgebander

Edgebander

FELDER - FORMAT4 tempora F600 60.06L

Edgebander

Productivity, flexibility and user comfort

Time, the most important resource in a modern workshop was the main focus whilst developing the tempora machine concept. Processing edges needs to be as quick, easy and efficient as possible. To achieve this, the tempora models combine the core skills of speed, productivity, flexibility and ease of use in a convincing complete package...

Request infos

FELDER – FORMAT4 tempora 60.06 L glueBox