—

FELDER - FORMAT4

PROFIT H08 16.31

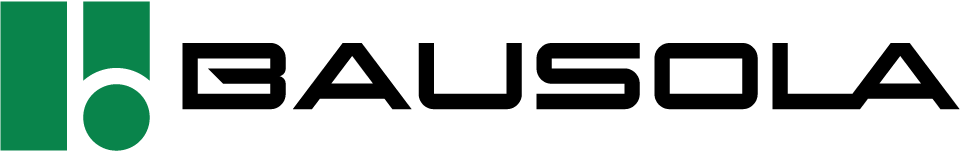

Nesting CNC Machining Centre

Code: 566

restore Production year: 2015 error_outline Status: Like new

domain Availability: 4 check_circle EC legislation: Compliant

Controlled axes number:

3

Boring head

Arms number:

Plan nesting

Description

Nesting CNC Machining Centre

FELDER – FORMAT4 PROFIT H08 16.31

CNC-NESTING – EFFICIENCY THROUGH AUTOMATION

Especially developed for universal application, this profitable CNC all-rounder convinces with top precision and impressive productivity when processing various different materials.

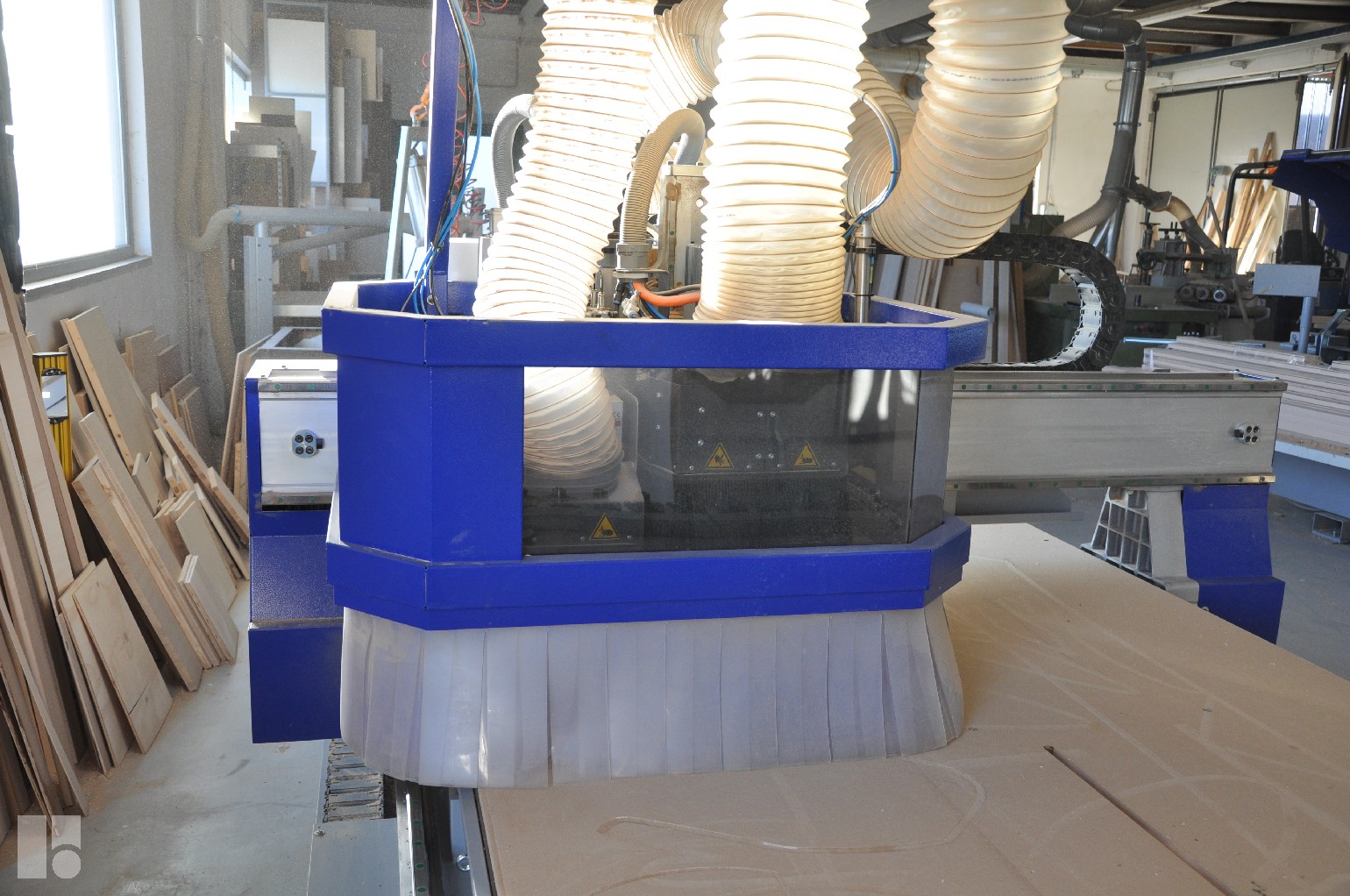

The profit H08 16.31 offers maximum flexibility and efficiency and already convinces in the basic equipment with 11 tool positions. For perfect, chip free results, the main spindle is equipped with a 9,2 kW motor. The main spindle is completed by a drilling head with.

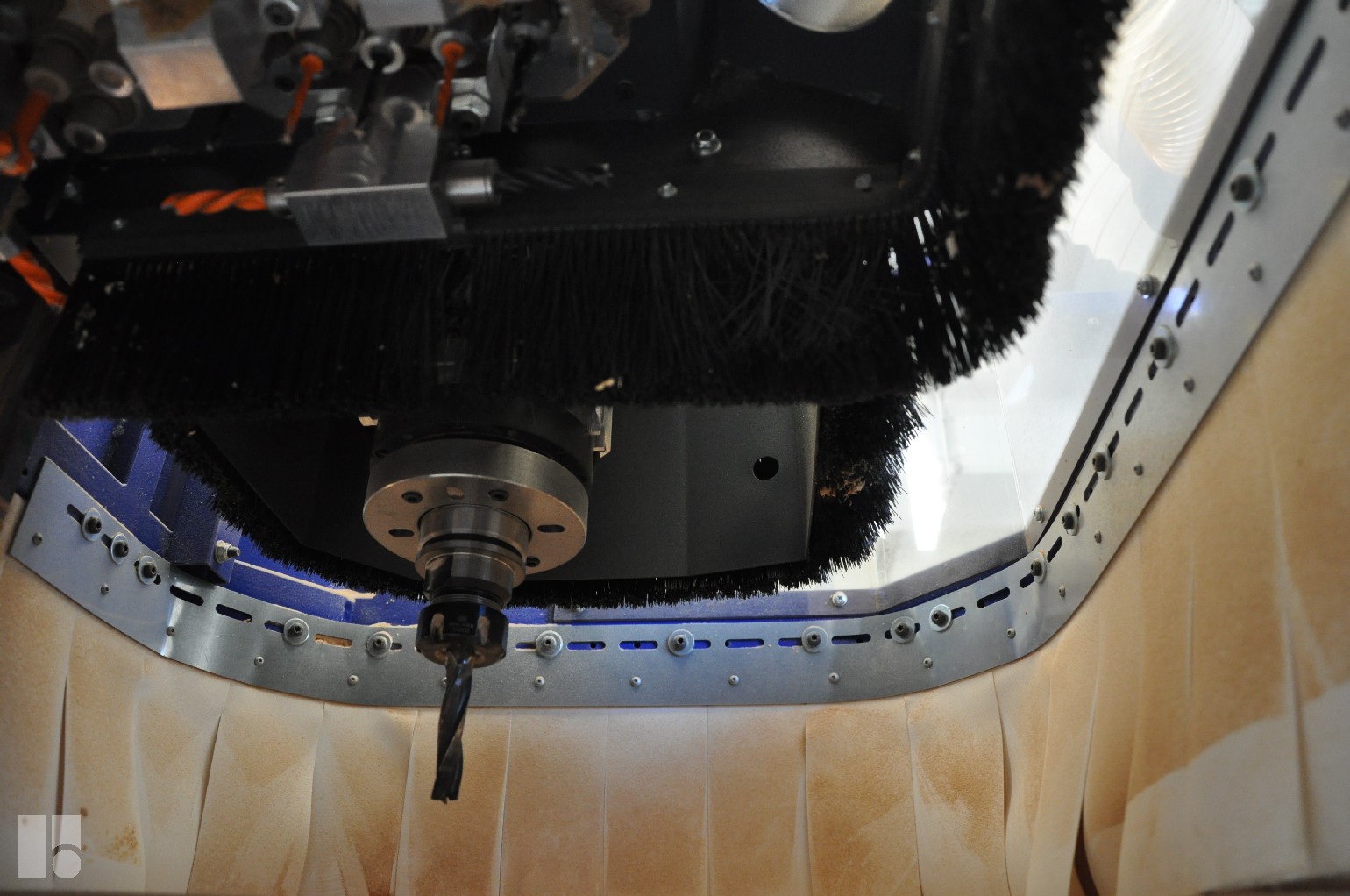

Due to the smart zoning vacuum control, the vacuum zones can be switched to either fully automatic or manual control and activated depending on the workpiece size. Individual workpieces with variable sizes can also be positioned and processed in the zones 1 to 6.

... FORMAT-4 Premium machines for premium requirements

- Tailor made financing solutions

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Compliance with CE regulations

- Automation solutions

- Networked workshop

- Software and machines from a single supplier

Technical details

Effective working

Effective X

3100 mm

Eeffective Y

1600 mm

Effective Z

80 mm

Details

Heads number

1

Controlled axes number

3

Main motor power

9,2 Kw

Mils connection drive motor

HSK 63F

Boring head

check_circle

Tools warehouse positions number

11

Arms number

Plan nesting

Security

Photocells

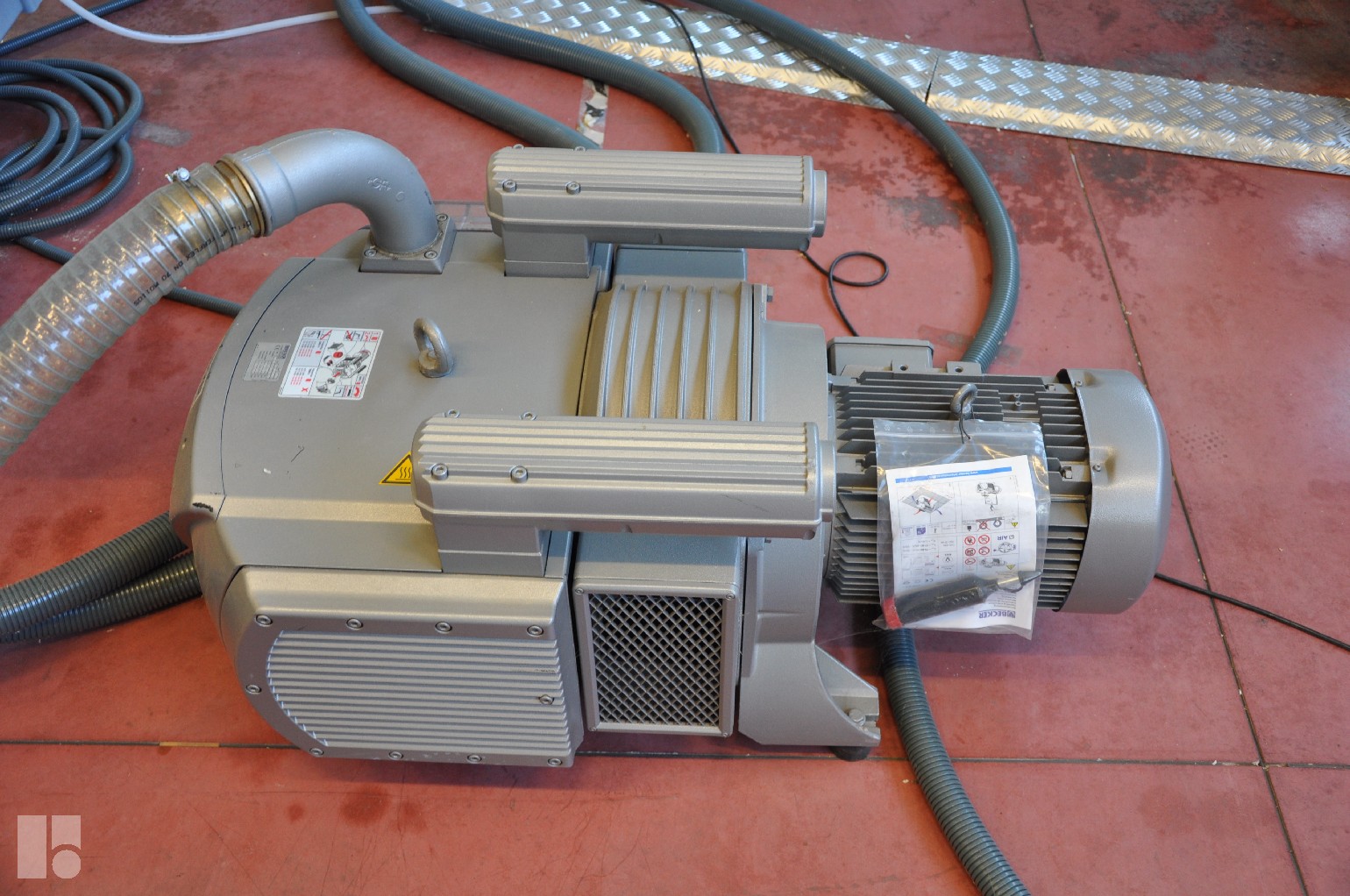

Vacuum pump

2 x 250 m3/h

Software/C.N.

Software

Woodflash + Flashnest

Generals

Sizes*

4600x2260x2000 mm

Weight*

3000 kg

Total kW*

25

*Shown values may vary depending on the configuration of the machine.

Related machineries

LARI e LARI FR300 TA TB 3F

CNC / Pantographs

Numerically controlled machining center for processing wooden window and door frames, complete with anuba boring head and mortising head

LARI e LARI FR300 TA TB 3F

CNC / Pantographs

Machining center for milling, anubing and plastering on wooden elements or plastic and composite materials.

Structure in stabilized steel tubing. Sliding on cemented and ground guides with recirculating ball slides.

Axis movements with racks and ball screws.

Linear, circular, helical, spline interpolation. Point programming.

N. 3 interpolated axes (X - Y - Z)

Worktop...

LARI e LARI P7

CNC / Pantographs

Numerical control machining centre

LARI e LARI P7

CNC / Pantographs

NC machining centre for milling, drilling, cutting, profiling, tenoning on wooden oer plastic and composite parts.

Structure in stabilised tubular steel. Running on casehardened and ground guides with bearings with 4 ball re-circulations.

Axis movements with racks and ball re-circulation screws with brushless and direct current motors.

Automatic positioning of X arms.<...

FELDER - FORMAT4 profit H350 16.30

CNC / Pantographs

Work center for windows and doors

FELDER - FORMAT4 profit H350 16.30

CNC / Pantographs

CNC machining center with a gantry structure (toolless) and digital drives (two-sided drive).

The machine base of the Profit H350 16.30 is made of thick-walled, electro-welded shaped tubes.

Steel ribs inside the base ensure high stability.

Machine composition:

Optical machine status indicator

Blue LED lighting strip, integrated into the front mount ...

LARI e LARI FR20 TA TB

CNC / Pantographs

Milling, chiesel and anuba work centre

LARI e LARI FR20 TA TB

CNC / Pantographs

Movement axes with racks and screws recirculating spheres.

Industrial numerical control.

Windows XP system.

TFT 12"s Color Video"

Linear, circular, helical, spline interpolation.

Parameter programming using pre-set macros.

Machine composition:

Electro spindle 3.4 kW at 18,000 rpm

ER32 staple attack

3 interpolated axes

Engine with tilt control...

Request infos

FELDER – FORMAT4 PROFIT H08 16.31