—

VITAP

POINT K2 TOP

Pass-through panel machining centre, drilling from below and automatic return to the operato

Code: 2110

restore Production year: 2017 error_outline Status: Good

domain Availability: In stock check_circle EC legislation: Compliant

Controlled axes number:

3

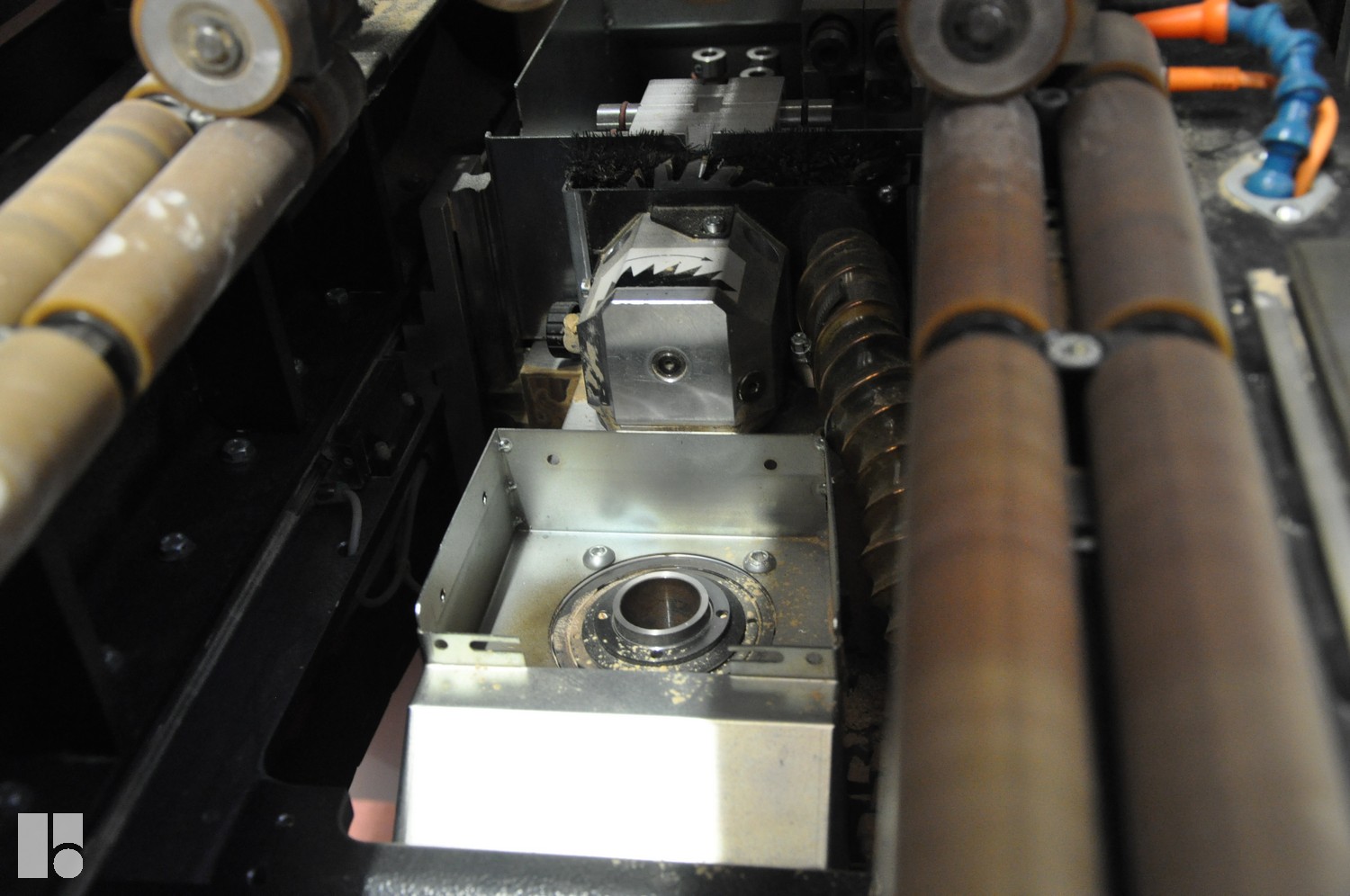

Boring head

Description

Pass-through panel machining centre, drilling from below and automatic return to the operato

VITAP POINT K2 TOP

Pass-through panel machining centre, drilling from below and automatic return to the operato

X axis - Panel movement with DDT (Double Dynamic Transport)

Double gripper system with enhanced brushless motor for seamless movement of the piece: it can also work with a single gripper for small-sized pieces.

It allows you to make channels and milling without interruption for the gripper to pick up. A notable stability of the milling piece is obtained.

Y axis - Drilling head movement with precision rack and pinion

Z axis - Panel drilling with ball screw movement

Double "0" panel: Laser sensor (controlled by the NC) for reading the end of the panel to create a double reference zero on the two ends of the panel in order to have equidistance for a perfect coupling of the vertical and horizontal pieces.

The latest generation laser has a transmitter and a receiver and is completely free from edge or color differences.

Constant pressing: Side aligner with constant preload for perfect positioning of the panel on the zero point of the machine.

Rear panel exit

Tool change from the front access door

Axis positioning: X and Y axis latest generation Brushless motor with planetary gearboxes and high precision rack with helical teeth

Latest generation Z axis and precision ball screw.

No panel length limit

High productivity and flexibility

Simple programming

Control: Full Parametric

Industrial PC for high programming performance

19" TFT LCD monitor

WSC user interface with Lister, Tool parametrics and tooling parametrics

TpaEdi32 graphic programming CAD in Basic version

Software for basic cutting and squaring

USB port to upload programs run on a CAD station in the office

3 levels of access with password (operator - supervisor - assistance)

Set up parameters

Work path configuration

Storage of all files with all data

Data entry form with graphic support on the main operations

Macro programming

Essential data always visible on the screen

Job list

Cross-check between parameters and work to be performed

DXF file import

TECHNICAL DATA

3.6 kW electrospindle with Iso 30 quick coupling (rpm 12000-24000)

Testa a forare:

1.5 kW motor

Number of vertical independent spindles: 12

Number of horizontal spindles X axis: (2+2)

Number of horizontal spindles for drilling on the Y axis: (2+2) (on the two long sides of the panel)

N° 1 saw for channel execution (diameter 100mm)

Max depth of all horizontal drillings in X and Y 30mm

Max vertical drilling depth 45 mm

Max horizontal tip diameter 12mm

Max vertical tip diameter 35 mm

Max. panel thickness 50 mm

Max panel weight: 80 kg

Max panel dimensions: X no limit, Y 1100 mm, Z 50mm

Min. dimensions panel: X 270/400 *, Y180 (70 op), Z4 mm

X-axis panel feed: 25m/min

Suction mouth diameter 120mm

Front and rear roller conveyor for long panels

Technical details

Effective working

Effective X

270 mm - nessun limite

Eeffective Y

180-1200 mm

Effective Z

12-50 mm

Details

Heads number

1

Controlled axes number

3

Main motor power

3,6 kW

Mils connection drive motor

ISO 30

Boring head

check_circle

Grips number (Optional)

2

Security

Cabin

Software/C.N.

Software

Edicad 32

Generals

Sizes*

2644x1900x1650 mm

Weight*

850 kg

Total kW*

8,5

*Shown values may vary depending on the configuration of the machine.

Related machineries

FELDER - FORMAT4 profit H22 XYLMAC

CNC / Pantographs

Machining center for windows and doors

FELDER - FORMAT4 profit H22 XYLMAC

CNC / Pantographs

The base of the H22 profit machining center is made up of high-thickness, electrically welded tubular sections.

X-axis guide system:

The X-axis arm is driven by a rack with inclined and curved teeth.

Y-axis guide system:

The Y axis is positioned with a ground ball screw.

Z axis sliding system:

The Z ...

FELDER - FORMAT4 Profit H22

CNC / Pantographs

Machining center for windows and doors

FELDER - FORMAT4 Profit H22

CNC / Pantographs

Machining center for windows and doors

The base of the H22 profit machining center is made up of high-thickness, electrically welded tubular sections

X-axis guide system:

The X-axis arm is driven by a rack with inclined and curved teeth

Y-axis guide system:

The Y axis is positioned with a ground ball screw

Z axis sliding system:

The Z axis...

LARI e LARI FR30 TA

CNC / Pantographs

Numerical control machining centre

LARI e LARI FR30 TA

CNC / Pantographs

Numerical control machining centre for milling operations, notching or cutting on wooden, plastic or composite parts.

Structure in stabilised tubular steel.

Running on ground guides with 4 ball recirculations.

Axis movements with BRUSHLESS/DIRECT CURRENT motors.

Main electric chuck 4.5 HP at 18,000 rpm..

Variable rpm by Inverter.

3 interpolated axes

Industr...

HOLZHER 7120F

CNC / Pantographs

Field of work:

- X: 3830 mm

- Y: 1148 mm

- Z: 180mm

- X "" Y "axis translation speed 78 m / min.

-Linear speed in the Z axis: 25 rpm.

-12KW HSK63F liquid-cooled electrospindle

VECTOR "C" AXIS for 360° rotation and positioning of angle heads with automatic rotation adjustment via numerical control.

Cooling system with spindle liquid

Independent fixed ...

Request infos

VITAP POINT K2 TOP