Blade diameter:

315 mm

Cut heght:

103 mm

Wagon length:

2050 mm

Parallel guidance cut wedth:

800 mm

Description

Saw/Spindle Moulder

HAMMER B3 winner

Cutting and moulding for the discerning woodworker!

With the B3 winner you, as a discerning woodworker, are investing in a combined panel saw and spindle moulder that is in a class of its own. The smooth action of the generously sized format sliding table will impress you even before you make the first cut. The panel saw and spindle moulder units have been optimised with regard to precision and performance.

Professional stops ensure exact cross and parallel cuts as well as spindle work.

Fast and easy: Innovative Hammer technology allows you to conveniently switch from one application to another.

... why you should choose a Hammer

- Excellent value for money

- Decision making reliability for many years to come

- Innovative machine technology

- Solid cast iron tables and units

- High quality, unique detail solutions as part of the standard package

- Top quality manufacturing with strict quality guidelines

- Remarkably user friendly

- Classic design

- Quality and precision from Austria

- Compact functionality

- Compliance with CE regulations

- Mobile as an option

- Minimal space requirement

- Quickest changeover times

Technical details

Circular blade system details

Blade diameter

315 mm

Cut heght

103 mm

Wagon length

2050 mm

Parallel guidance cut wedth

800 mm

Adjustable rotation speed

check_circle

Spindle moulding machines system details

Shaft diameter

30 mm

Shaft length

100 mm

Tilting spindle

check_circle

Movement type

Manual

Tenoning

check_circle

Extensible frame

check_circle

Generals

Sizes*

2200x2400x1300 mm

Weight*

400 kg

Total kW*

3

Single-phase

check_circle

*Shown values may vary depending on the configuration of the machine.

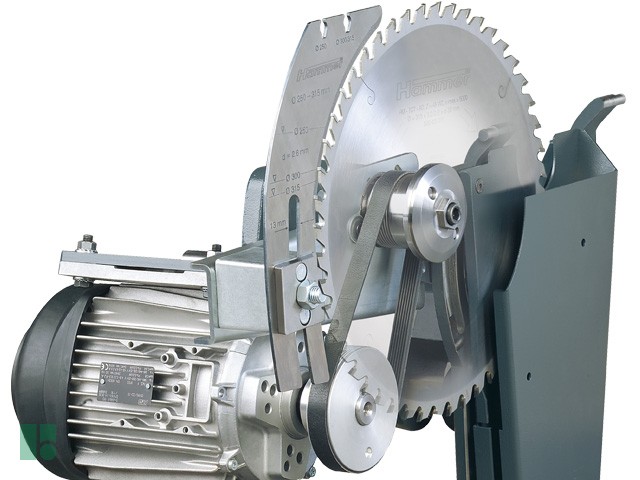

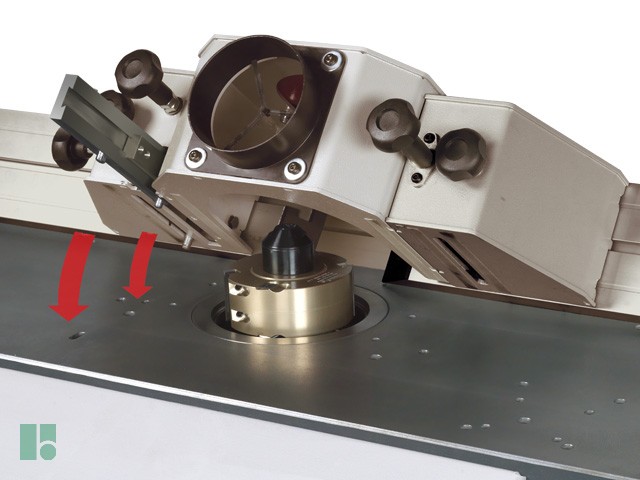

Stable-compact-precise, the Hammer saw aggregate

Saw blade tilt 90°-45°

Grooving, slot and tenoning with the saw

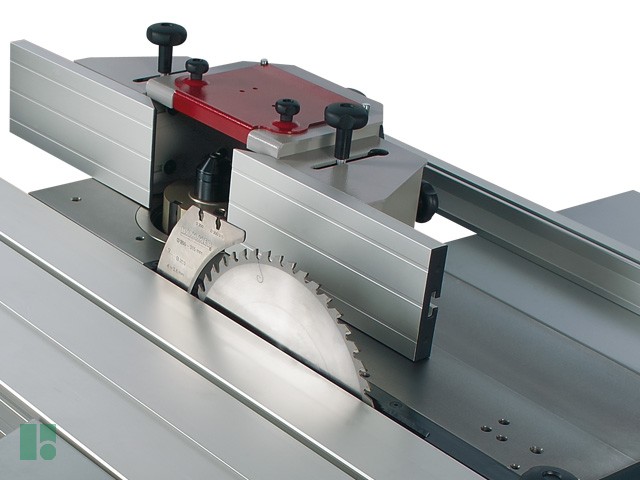

Scoring unit for laminated workpieces (Optional)

The aluminium sliding table, the heart of every panel saw

The Hammer saw/spindle table, made from solid cast iron

Outrigger table for heavy workpieces

Index plunger

Crosscut fence for precise mitre cuts

Rip fence on the saw table

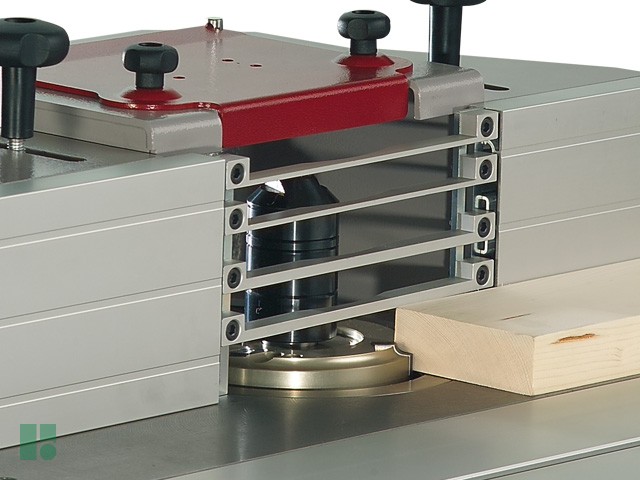

Stability and operating smoothness - the Hammer spindle moulder unit

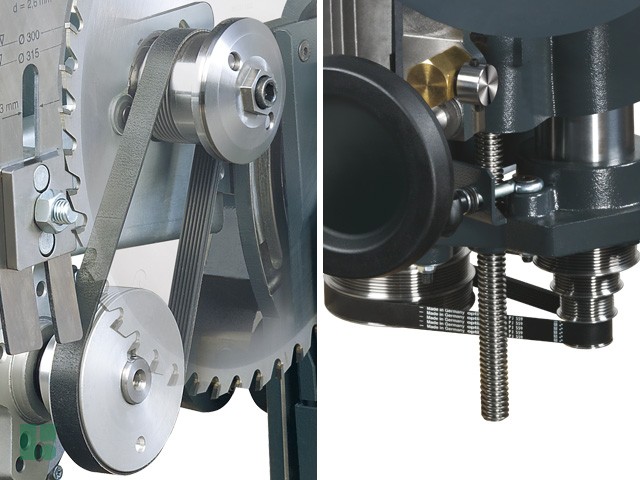

Strong motors - Optimal power transmission

Spindle

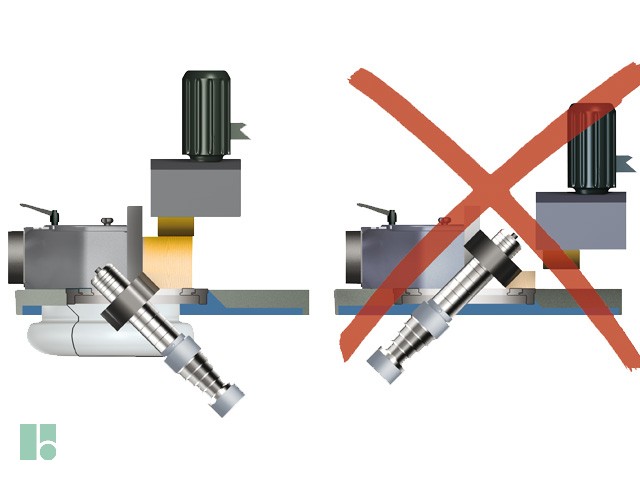

Your Felder spindle tilts “rearward” for operational comfort and the additional following reasons:

- Safety, as there is no pinch point

- Suitable for any workpiece size

- Problem-free power feeder application

- Impeccable machined surface

- Optimal chip removal

MF spindle system

Spindle fence: simple handling, maximum safety and precision

Multi fine adjustment system

Safety bar guides (Optional)

As an option: Adapt the table size to the workpiece dimension

Minimal space requirement - mobile in every workshop

Hammer - Decision making reliability for many years to come

Related machineries

FELDER KF 700 S Professional

Tenoning / Squaring machines

Saw/Spindle moulder

FELDER KF 700 S Professional

Tenoning / Squaring machines

Two professional machines in one combination

Panel saw and tilting spindle moulder – with the KF 700 saw-spindle moulder Felder has combined two top quality professional woodworking machines forming an unbeatable combination. Innovative detail solutions, tried and tested Felder technology and perfect components for perfect woodworking.

... Your decision for Felde...

Request infos

HAMMER B3 winner

.jpg)