—

FELDER - c-tech

profit H10

CNC for dissecting, pantographing and drilling of ACM composite aluminum panels (Alucobond®, dibond®), fibrocement, drywall, high-pressure plastic laminate (HPL), aluminum honeycomb (Alucore®, Larcore®, Plascore®) and Corian®

Controlled axes number:

3

Description

CNC for dissecting, pantographing and drilling of ACM composite aluminum panels (Alucobond®, dibond®), fibrocement, drywall, high-pressure plastic laminate (HPL), aluminum honeycomb (Alucore®, Larcore®, Plascore®) and Corian®

FELDER – c-tech profit H10

Panel cutting, drilling and milling in any shape desired, all in one process!

CNC Cutting

- Load panel, start working. Once loaded, the profit H10 works without an operator. No additional programing is required.

- Freeform shaping cut: any shape possible

- Minimum material waste thanks to CNC Nesting technology

- Highly precise cut edges, shaping cut = format cut, processed items are immediately ready to be processed on an edgebander without a premilling unit

CNC Drilling

- Material does not need to be processed further by a CNC or drilling machine

- Significant time savings thanks to a combination of CNC cutting and CNC drilling in just one work cycle

- Workpieces are fitted with bore holes or rows of bore holes before or after the shaping cut

- Processed items are immediately ready for processing on an edgebander

CNC Nesting (nesting)

- Any desired shape can be used. Minumum waste thanks to nesting software

- Significant time savings thanks to a combination of CNC cutting, CNC drilling and CNC nesting in just one working cycle

- Workpieces are fitted with bore holes or rows of bore holes before or after the shaping cut

- Processed items are immediately ready for processing on an edgebander

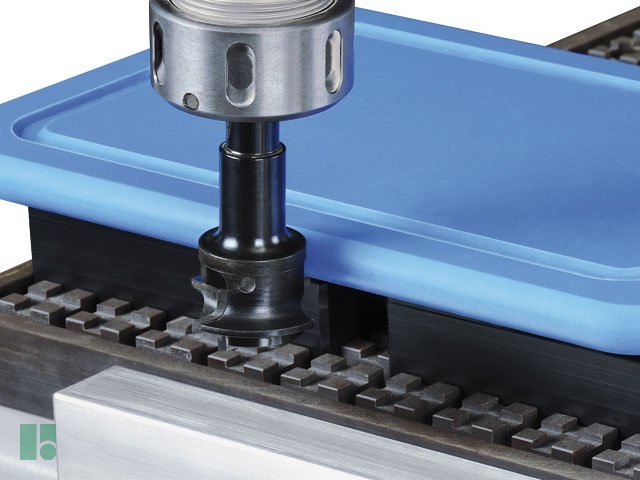

CNC Milling

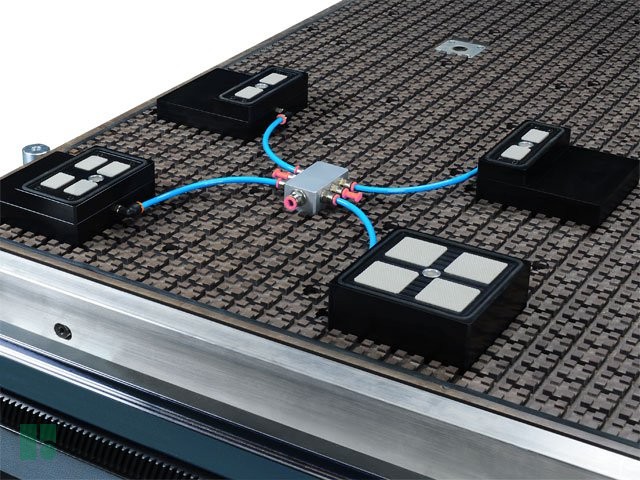

- Matrix table can be fitted with vacuum pods; CNC milling operations can be carried out just as in standard CNC machines

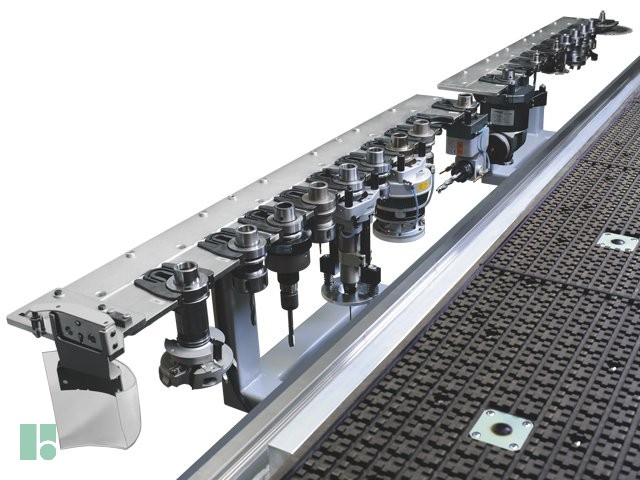

- Up to 36 tool slots available for CNC milling

Technical details

Effective working

Effective X

3120 mm (4300 mm)

Eeffective Y

2160 mm

Effective Z

105 mm

Details

Heads number

1

Controlled axes number

3

Main motor power

10 Kw

Mils connection drive motor

HSK 63F

Tools warehouse positions number

8

Arms number

Plan Nesting

Security

Photocels

Vacuum pump

2 x 250 m3h

Software/C.N.

Software

Woodflash

Generals

Sizes*

8000x4750x2510 mm

Weight*

4400 kg

Total kW*

24

*Shown values may vary depending on the configuration of the machine.

Quick and easy positioning of the vacuum pods, suitable for every workpiece size

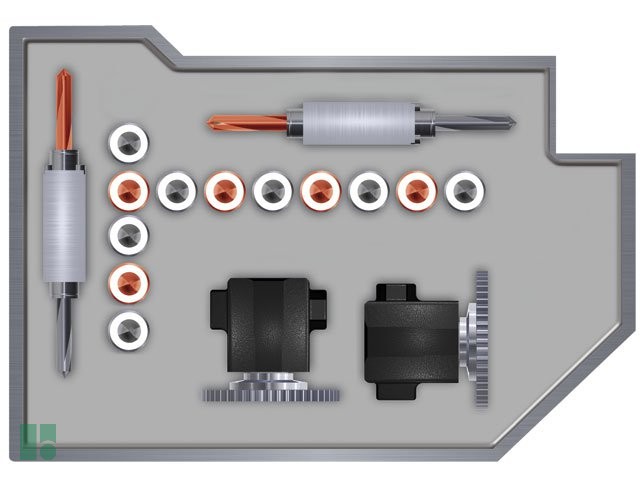

Tool change

Drilling head

Length measurement system

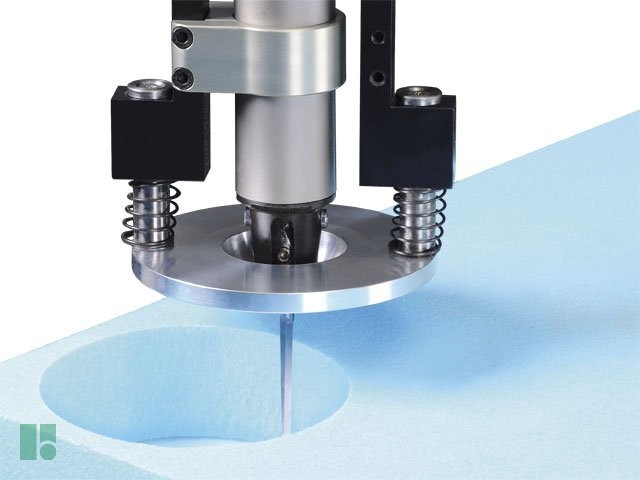

Cutting foam

Lamello

Edge processing

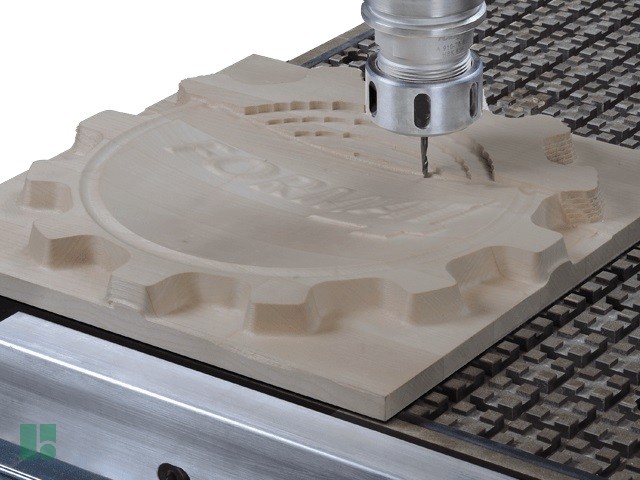

Engraving

Customised maintenance complete package

3D-Milling machine

Related machineries

FELDER - c-tech safeSpace

CNC c-tech

c-tech CNC-Innovation FORMAT-4 safeSpace

FELDER - c-tech safeSpace

CNC c-tech

SAFETY IN THE SMALLEST OF SPACES

The CNC machining centres profit H350, H300 and H200, enclosed on all sides by the Format-4 safeSpace, bring the most modern of CNC technology even to smaller workshops. Up to 7.5 m² less installation space required, but with massively increased working safety - that is the CNC advantage of machines from Format-4.

- Everythin...

Request infos

FELDER – c-tech profit H10