—

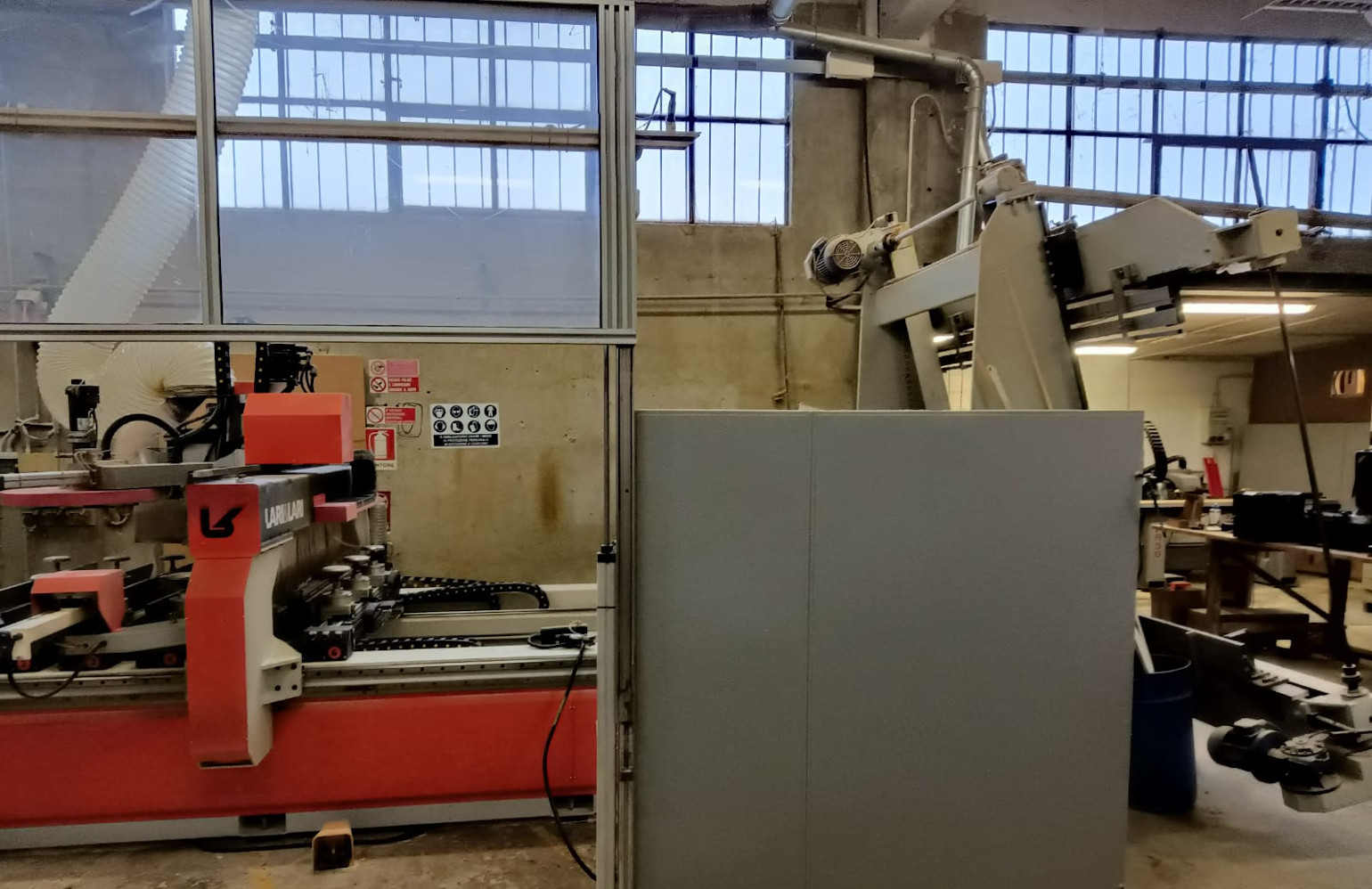

LARI e LARI

P7

Numerical control machining centre

Code: 1405

restore Production year: 2009 error_outline Status: Good

domain Availability: In stock check_circle EC legislation: Compliant

Controlled axes number:

4

Arms number:

6

Description

Numerical control machining centre

LARI e LARI P7

NC machining centre for milling, drilling, cutting, profiling, tenoning on wooden oer plastic and composite parts.

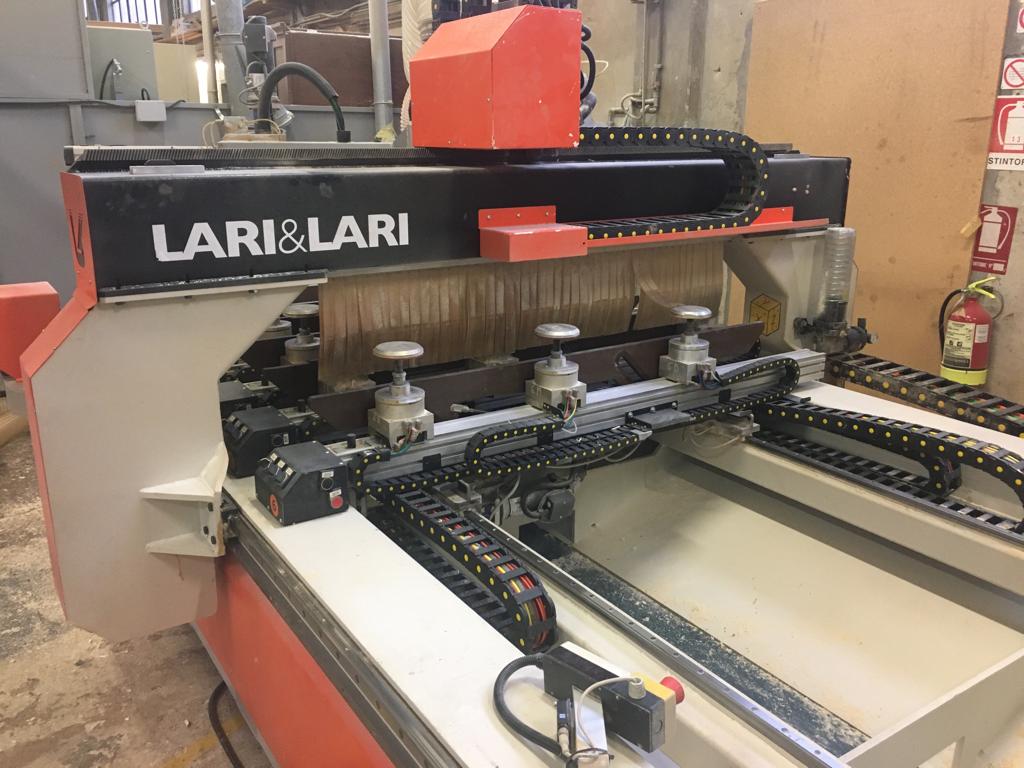

Structure in stabilised tubular steel. Running on casehardened and ground guides with bearings with 4 ball re-circulations.

Axis movements with racks and ball re-circulation screws with brushless and direct current motors.

Automatic positioning of X arms.

Traction presser with pneumatic control for locking and unlocking the upper part.

Reference beat in Y.

Clamp positioning beat.

Left side reference bar.

Pneumatic lift by bakelite bar.

Tool change with 14 positions on the right side of the crankcase.

N. 2 Tool change with 8 positions on machine bridge.

C-axis

Remote handheld keypad

Laser device to determine the position of the machine bites or points of the machine (No. 3 Laser)

Conveyor system dfridi of processing with conveyor belt placed under the plane of the machine.

Technical data:

Speed axis X = 90 mt/min

Speed axis Y = 60 mt/min

Speed axis Z = 20 mt/min

Technical details

Effective working

Effective X

4000 mm

Eeffective Y

2000 mm

Effective Z

270 mm

Details

Heads number

1

Controlled axes number

4

Main motor power

15 kW

Mils connection drive motor

HSK 63F

Tools warehouse positions number

14 + 8 + 8

Arms number

6

Grips number (Optional)

14

Evacuation carpet chips (Optional)

check_circle

Security

Cabin

Software/C.N.

Software

Dedicated + Pegasus cad/cam

Generals

Sizes*

7000x4500x2100 mm

Weight*

4200 kg

Total kW*

30

*Shown values may vary depending on the configuration of the machine.

Related machineries

MASTERWOOD TEKNOMAT 2004 F

CNC / Pantographs

Numerically controlled milling/anuba head machine

MASTERWOOD TEKNOMAT 2004 F

CNC / Pantographs

Top dimension mm 3300 x 260

Maximum distance between the 2 external anubas mm 2700

Maximum height with head positioned 0° mm 200

Maximum thickness with head positioned at 90° mm 120

Group of anubatura - Drilling motor Hp 1 - Screwing motor Hp 1

Tilt managed by control from -7° - +90°

Axis speed:

X axis m/min 40

Y axis m/min 7

Z axis m/min 7

VITAP POINT K2

CNC / Pantographs

Pass-through panel machining centre, drilling from below and automatic return to the operato

VITAP POINT K2

CNC / Pantographs

X axis - Panel movement with DDT (Double Dynamic Transport)

Double gripper system with enhanced brushless motor for seamless movement of the piece: it can also work with a single gripper for small-sized pieces.

It allows you to make channels and milling without interruption for the gripper to pick up. A notable stability of the milling piece is obtained.

Y axis - Drilling head movem...

LARI e LARI FR30 TA

CNC / Pantographs

Numerical control machining centre

LARI e LARI FR30 TA

CNC / Pantographs

Numerical control machining centre for milling operations, notching or cutting on wooden, plastic or composite parts.

Structure in stabilised tubular steel.

Running on ground guides with 4 ball recirculations.

Axis movements with BRUSHLESS/DIRECT CURRENT motors.

Main electric chuck 4.5 HP at 18,000 rpm..

Variable rpm by Inverter.

3 interpolated axes

Industr...

LARI e LARI FR300 TA TB 3F

CNC / Pantographs

Numerically controlled machining center for processing wooden window and door frames, complete with anuba boring head and mortising head

LARI e LARI FR300 TA TB 3F

CNC / Pantographs

Machining center for milling, anubing and plastering on wooden elements or plastic and composite materials.

Structure in stabilized steel tubing. Sliding on cemented and ground guides with recirculating ball slides.

Axis movements with racks and ball screws.

Linear, circular, helical, spline interpolation. Point programming.

N. 3 interpolated axes (X - Y - Z)

Worktop...

Request infos

LARI e LARI P7