—

VITAP

POINT K2

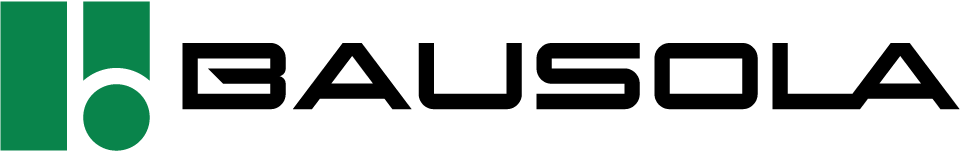

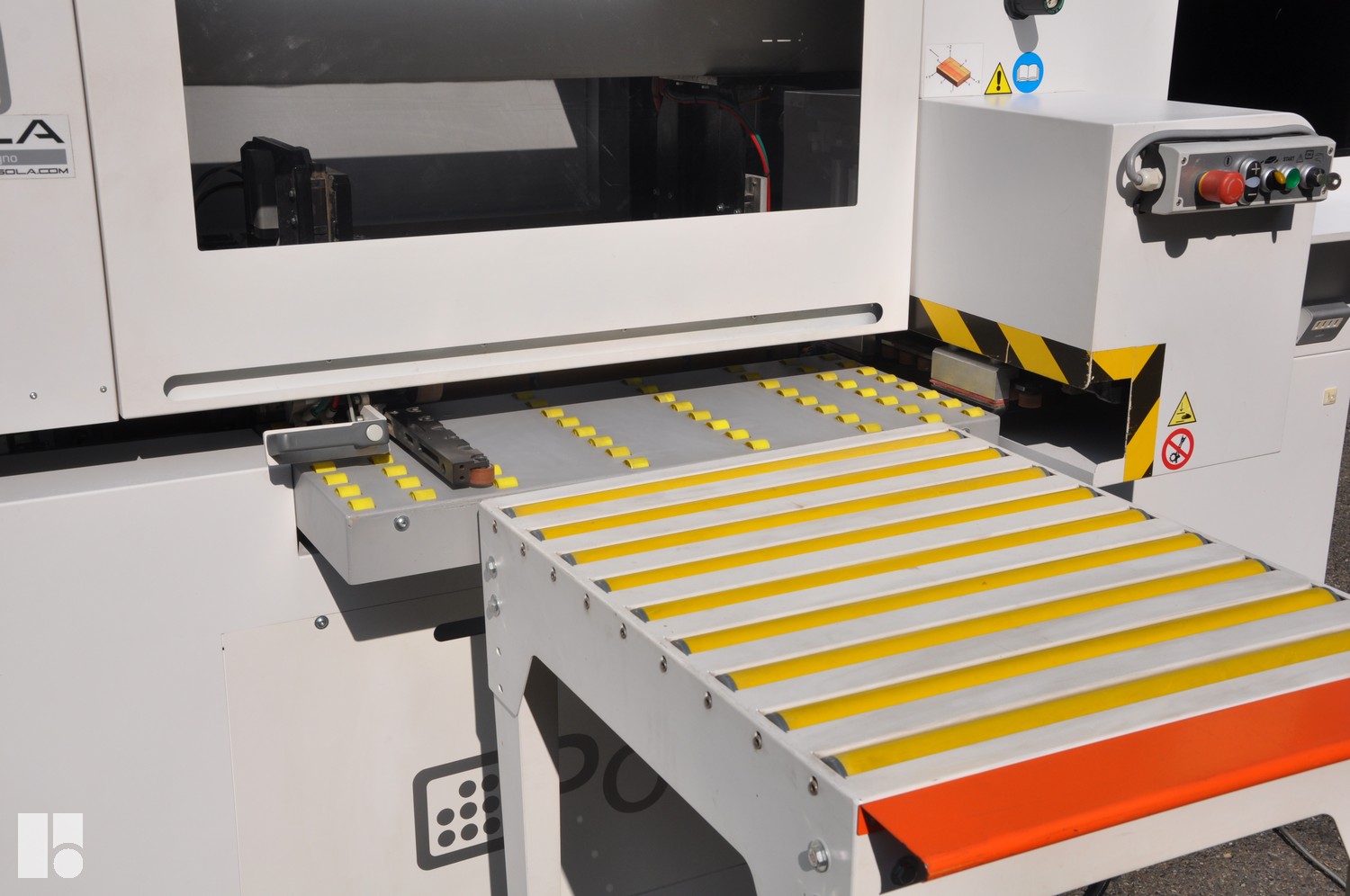

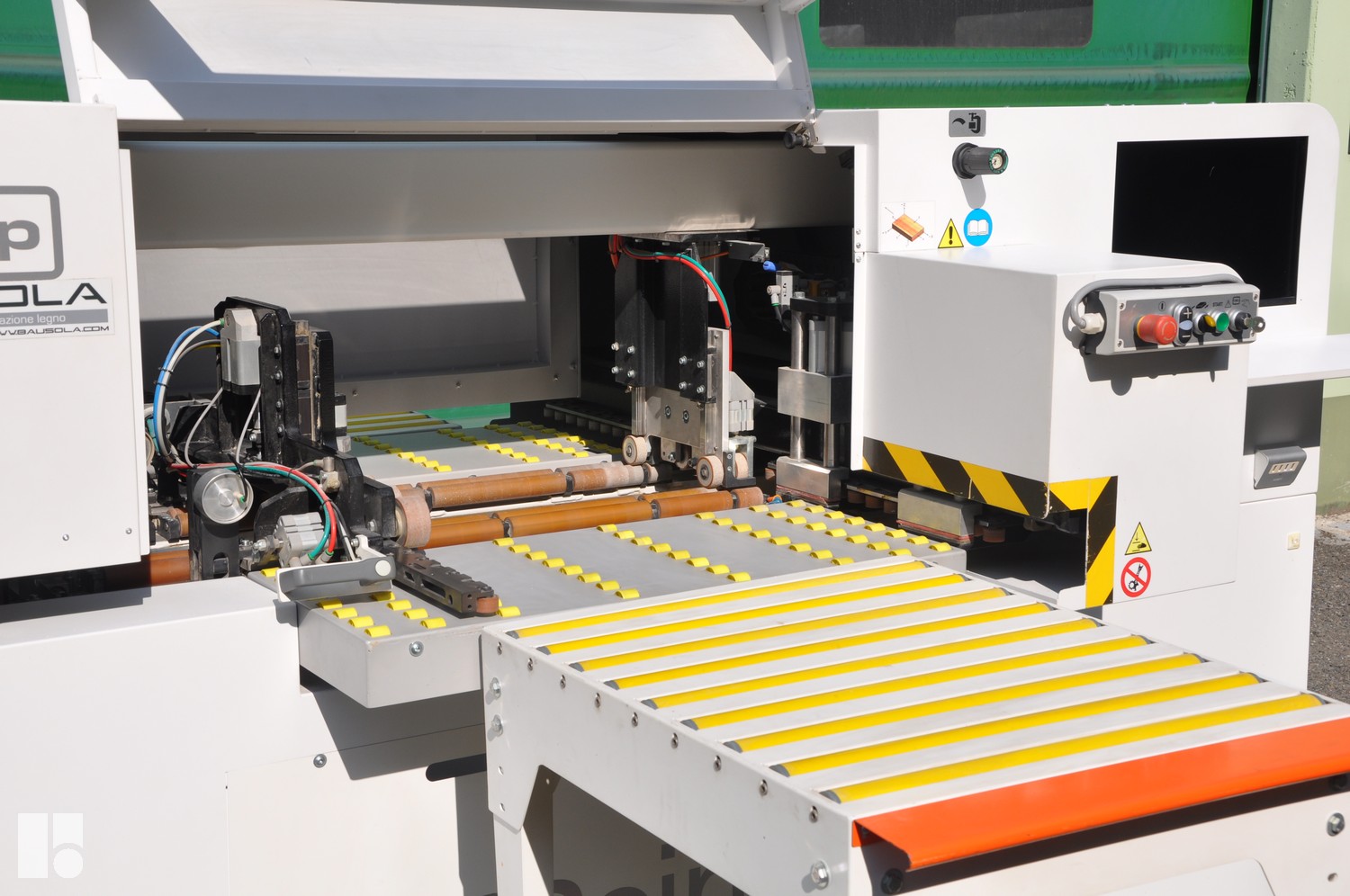

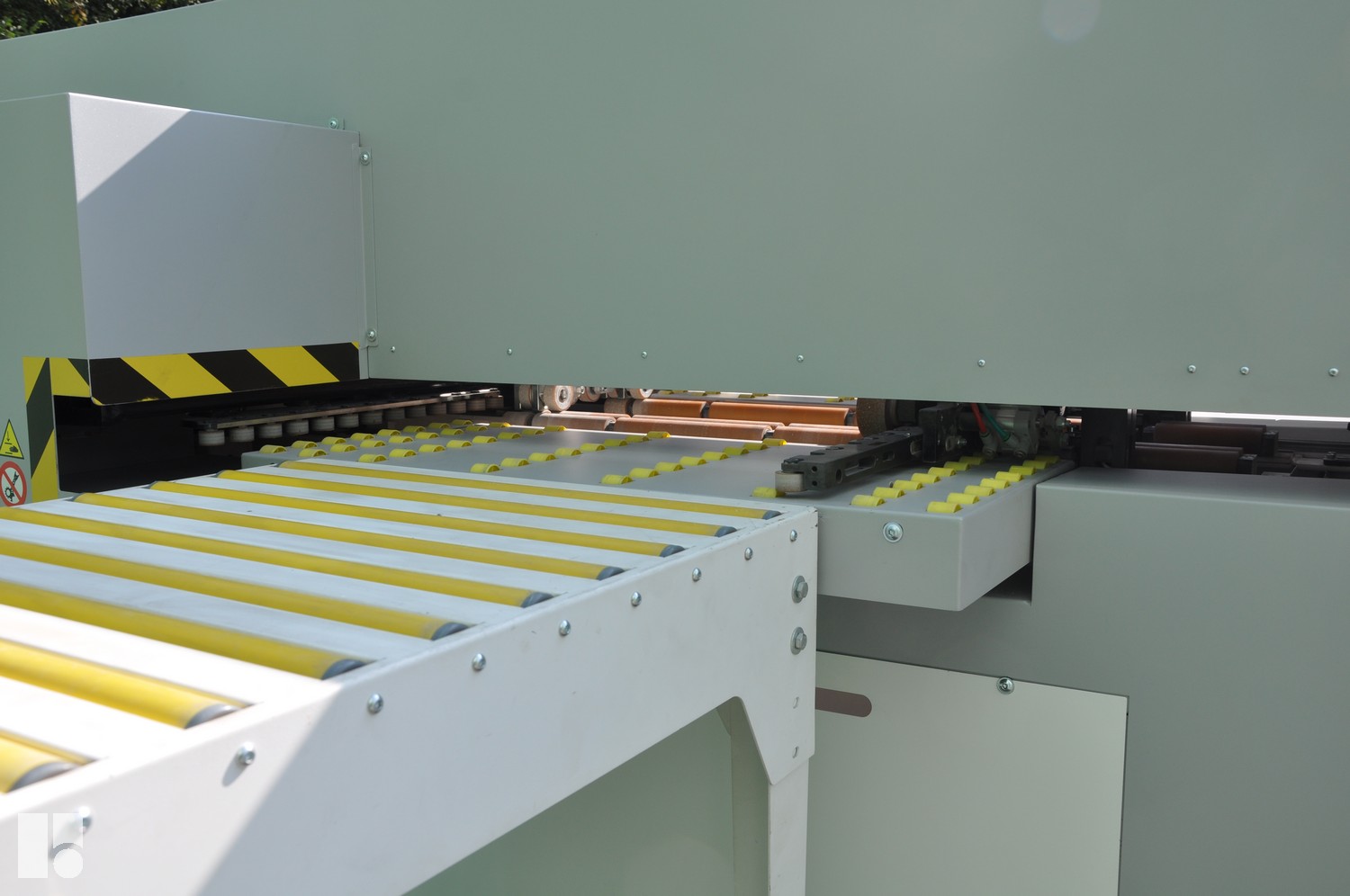

Electronic Milling/Drilling machine with pass-through panel

Code: 1332

restore Production year: 2016 error_outline Status: Good

domain Availability: In stock check_circle EC legislation: Compliant

Controlled axes number:

3

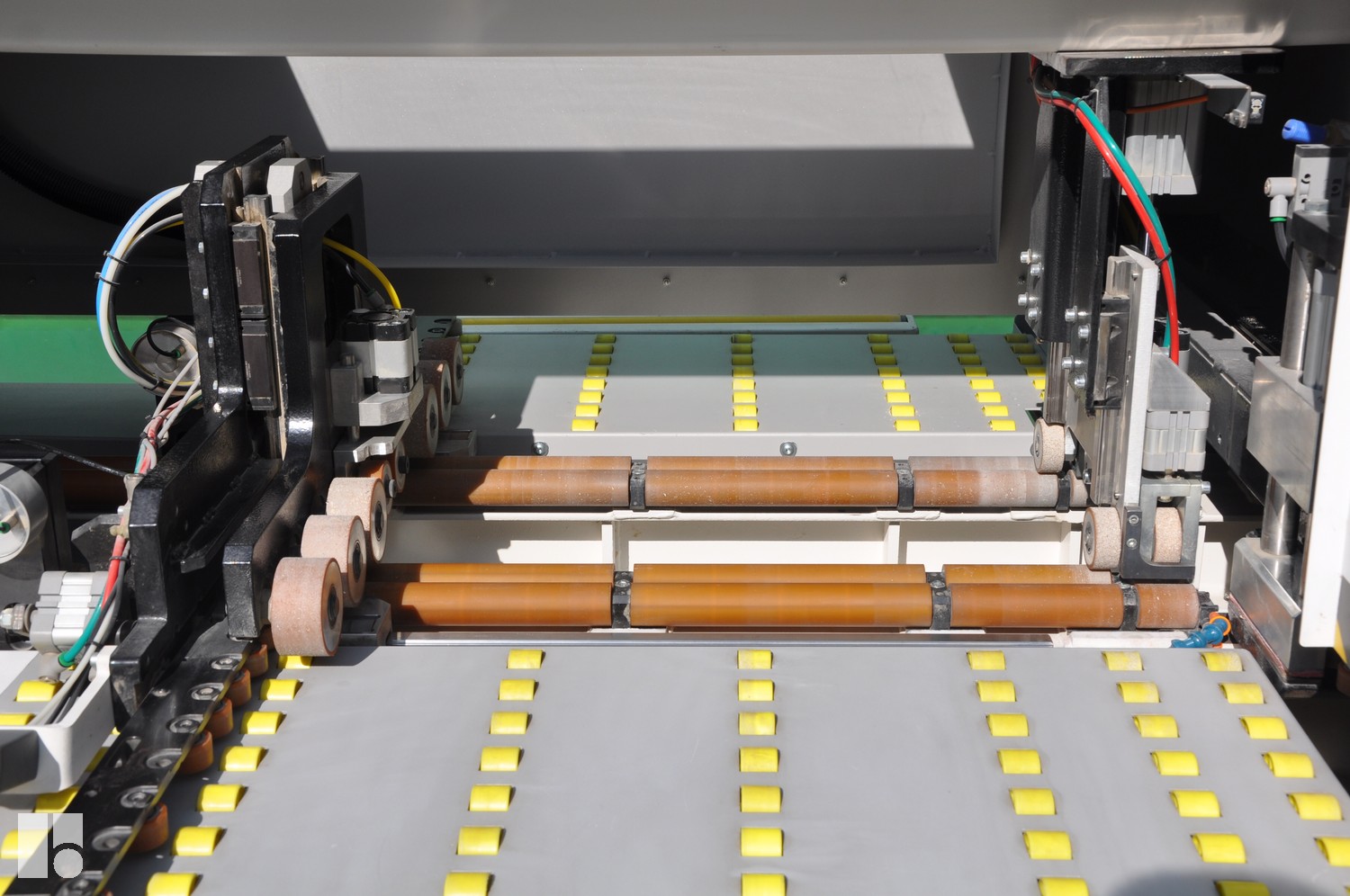

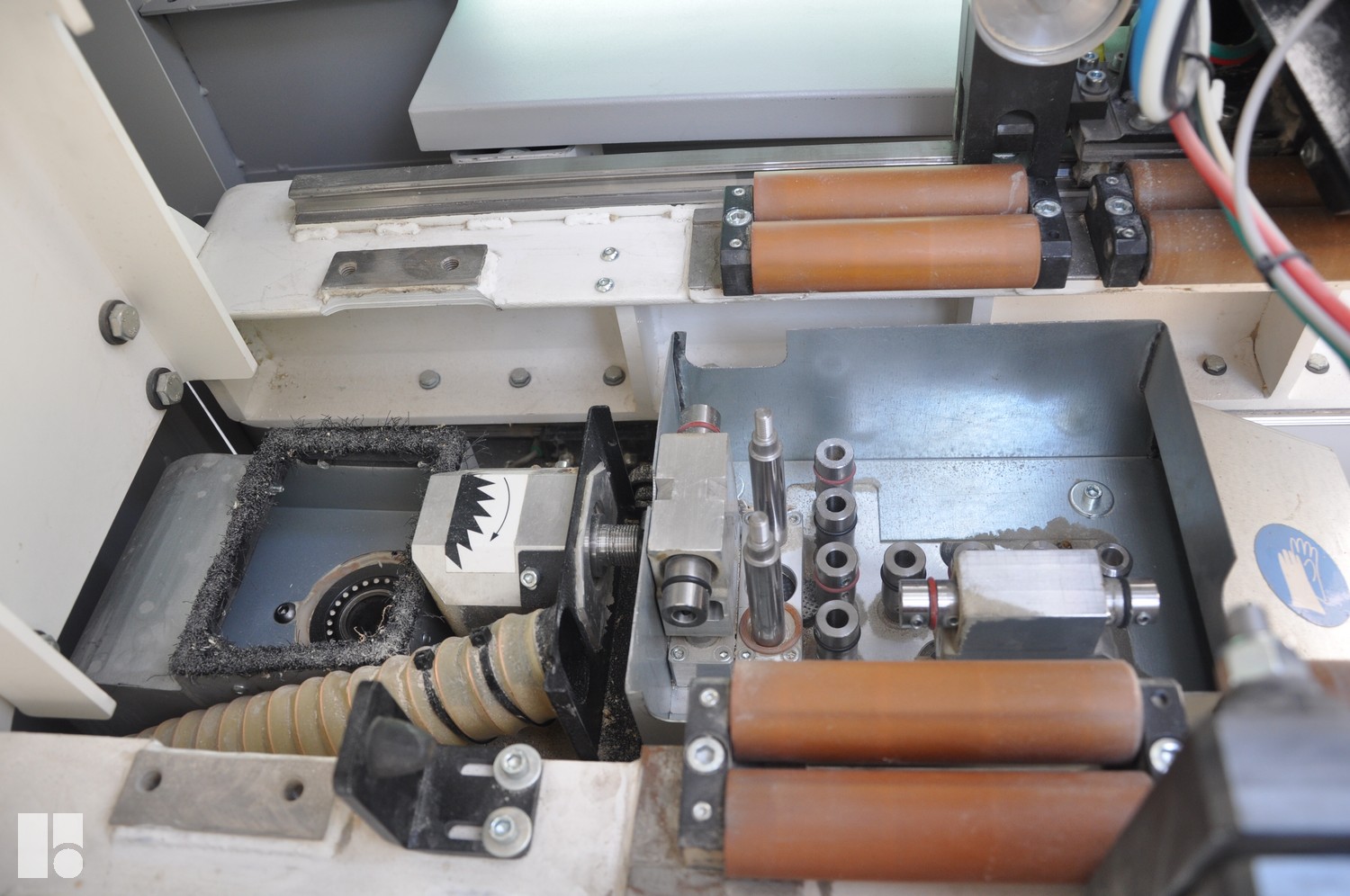

Boring head

Description

Electronic Milling/Drilling machine with pass-through panel

VITAP POINT K2

3.6 kW electrospindle with Iso 30 quick coupling (rpm 12000-24000)

Drilling head consisting of:

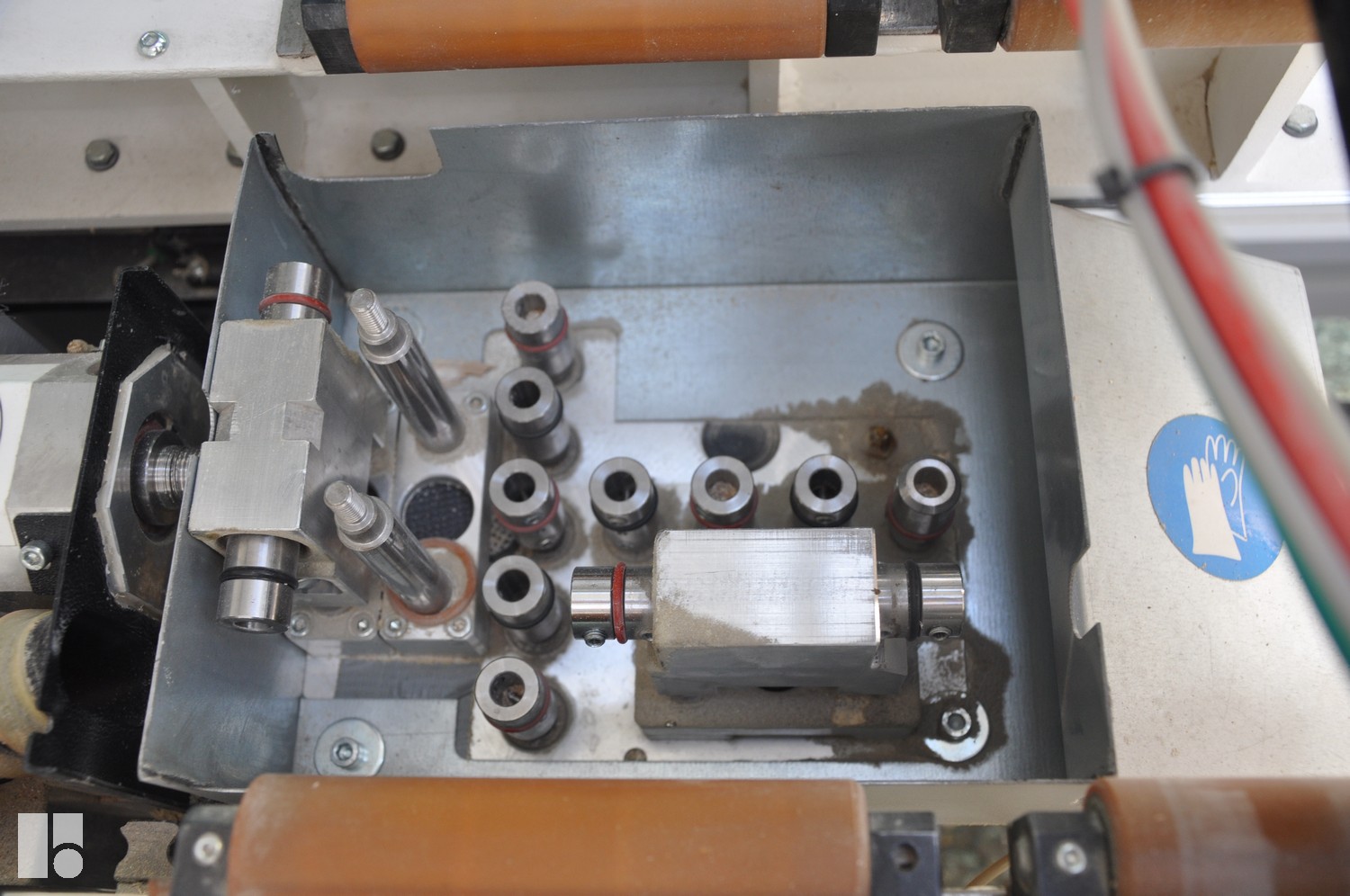

Number of independent vertical spindles: 9

Number of horizontal spindles on the X-axis: (1+1)

Number (1+1) horizontal spindle for drilling on the Y-axis (on the two long sides of the panel)

Number 1 saw for channel cutting (diameter 100 mm)

Technical data:

Max. panel thickness: 50 mm

Max. panel weight: 35 kg

Max. panel dimensions: X no limit, Y 1100 mm, Z 50 mm

Min. panel dimensions: X 270/400 *, Y 180, Z 12 mm (* at 270 mm with limitations)

X-axis panel feed: 25 m/min

Spindle rotation: 3600 rpm

Suction nozzle diameter: 120 mm

Max. depth of all horizontal drillings in X and Y: 30 mm

Max. vertical drilling depth: 45 mm

Max. horizontal drill diameter: 12 mm

Max. vertical drill diameter: 35 mm

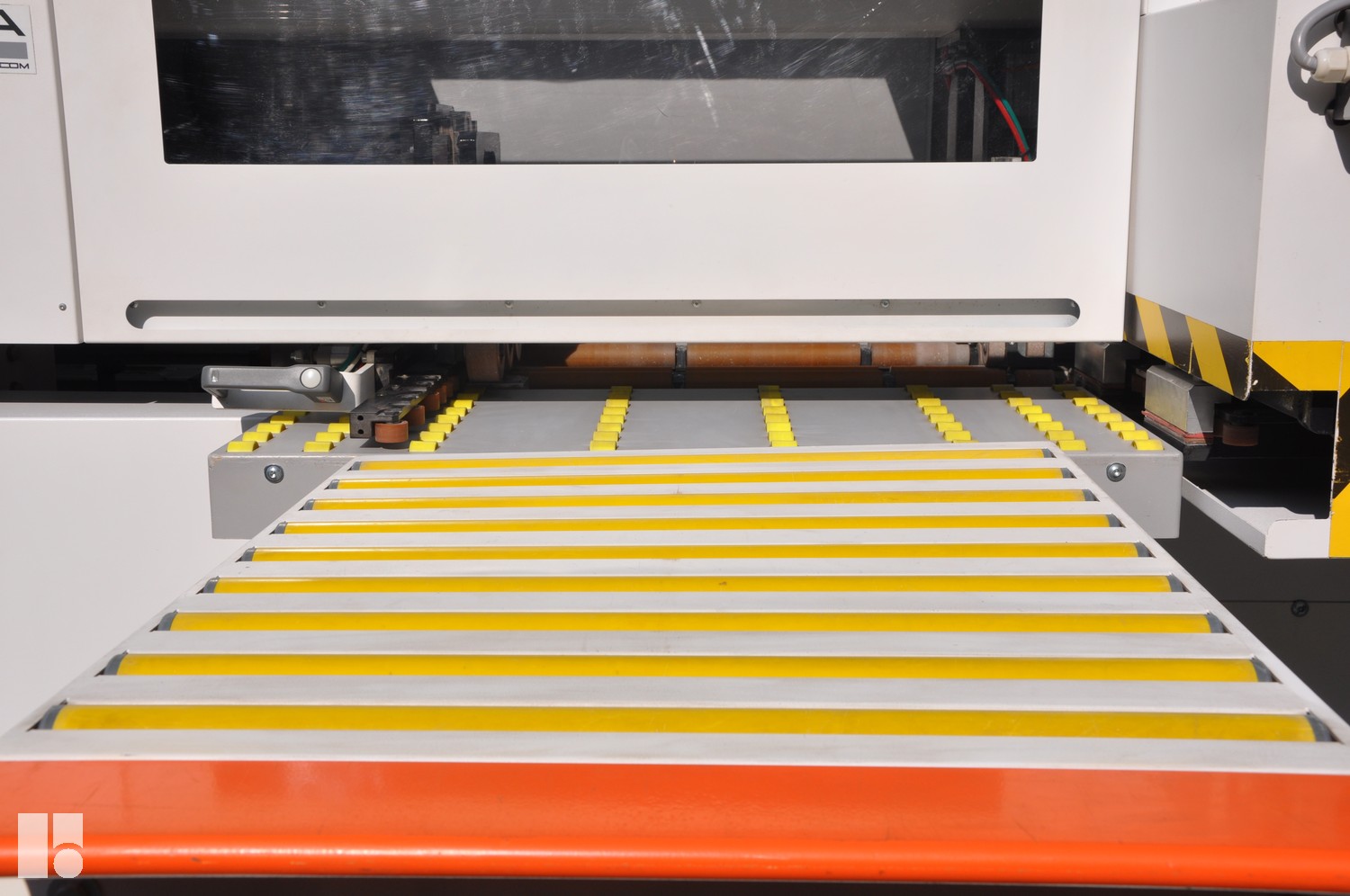

Front and rear roller conveyor for long panels

Technical details

Effective working

Effective X

270 mm - nessun limite

Eeffective Y

180 - 1100 mm

Effective Z

12 - 50 mm

Details

Heads number

1

Controlled axes number

3

Main motor power

3,6 kW

Mils connection drive motor

ISO 30

Boring head

check_circle

Security

Cabin

Software/C.N.

Software

TpaEdi32

Generals

Sizes*

2530x1680x1600 mm

Weight*

900 kg

Total kW*

6,4

*Shown values may vary depending on the configuration of the machine.

Related machineries

FELDER - FORMAT4 profit H22 XYLMAC

CNC / Pantographs

Machining center for windows and doors

FELDER - FORMAT4 profit H22 XYLMAC

CNC / Pantographs

The base of the H22 profit machining center is made up of high-thickness, electrically welded tubular sections.

X-axis guide system:

The X-axis arm is driven by a rack with inclined and curved teeth.

Y-axis guide system:

The Y axis is positioned with a ground ball screw.

Z axis sliding system:

The Z ...

FELDER - FORMAT4 PROFIT H08 16.31

CNC / Pantographs

Nesting CNC Machining Centre

FELDER - FORMAT4 PROFIT H08 16.31

CNC / Pantographs

CNC-NESTING – EFFICIENCY THROUGH AUTOMATION

Especially developed for universal application, this profitable CNC all-rounder convinces with top precision and impressive productivity when processing various different materials.

The profit H08 16.31 offers maximum flexibility and efficiency and already convinces in the basic equipment with 11 tool positions. For perf...

LARI e LARI FR300 TA TB 3F

CNC / Pantographs

Numerically controlled machining center for processing wooden window and door frames, complete with anuba boring head and mortising head

LARI e LARI FR300 TA TB 3F

CNC / Pantographs

Machining center for milling, anubing and plastering on wooden elements or plastic and composite materials.

Structure in stabilized steel tubing. Sliding on cemented and ground guides with recirculating ball slides.

Axis movements with racks and ball screws.

Linear, circular, helical, spline interpolation. Point programming.

N. 3 interpolated axes (X - Y - Z)

Worktop...

FELDER - FORMAT4 profit H350 16.30

CNC / Pantographs

Work center for windows and doors

FELDER - FORMAT4 profit H350 16.30

CNC / Pantographs

CNC machining center with a gantry structure (toolless) and digital drives (two-sided drive).

The machine base of the Profit H350 16.30 is made of thick-walled, electro-welded shaped tubes.

Steel ribs inside the base ensure high stability.

Machine composition:

Optical machine status indicator

Blue LED lighting strip, integrated into the front mount ...

Request infos

VITAP POINT K2