—

BAUSOLA UNITRON

Cutting-off, defecting, optimising machine for wooden bars

Effective length:

6000 mm

Blade diameter:

350 mm

Defecting machine

Optimizer

Description

Cutting-off, defecting, optimising machine for wooden bars

BAUSOLA UNITRON

Automatic cutting-off cycle.

Possibilità of selecting many typologies in order to optimise (.min waste, max length...).

Equipped with:

Vertical louder

Defect reading and self measurement of piece length

Upper blade

Returning of cut-off pieces to the operator with storage under the loader top

Touch screen monitor with dedicated software

Possibility of loading distinct for office ink-jet print or label marker

Technical specifications:

- Down 3-speed blade for cutting aluminum,louvers of shutters

- Blade Ø 350/400 mm

- Maximum section cutting 150x100 mm

- Wood floor support 6000 mm

- Automatic loader for louvers maximum length 5000 mm

- N. 1 suction duct Ø 60 mm

- N. 1 blade motor 3 kW (hp 4)

- N. 1 Brushlless motor for clampe 750 w

- Down 3-speed blade for cutting aluminum

- Pushing system with pneumatic nipper and back scraps ejector with Brushless motor

- Reading with the defects observed bt optical fluorescent crayons

- System for back offload of luvers, styles or treansom scraps

- Return mat for pieces to operator and cutted storage under the support plane of wooden bars

- Monitor touch screen with PLC exit, parallel for printer, net

- Dedicated software

Technical details

Effective working

Effective height

85 mm

Effective width

140 mm

Effective length

6000 mm

Details

Cut

Automatic

Blade diameter

350 mm

Superior cut

check_circle

Defecting machine

check_circle

Optimizer

check_circle

Software/C.N.

Optimising software

check_circle

Generals

Sizes*

9500x1500x1600 mm

Weight*

1600 kg

Total kW*

5

*Shown values may vary depending on the configuration of the machine.

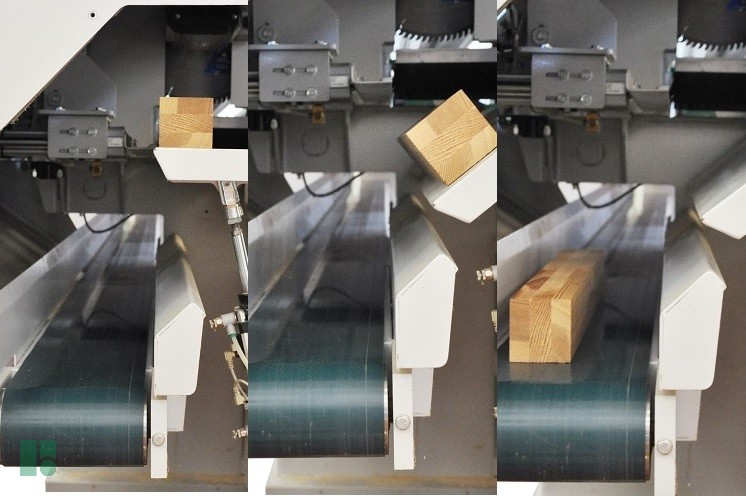

Pushing system with pneumatic nipper and back scraps ejector with brushless motor

The clamp is complete with automatic piece length reading and lens for detecting defects on wood (knots, resin pockets, etc.).

The electronic management of this device makes it possible to optimize the cutting sequences to the maximum reducing the production waste.

Blade group

N. 3 cutting speeds programmable by numerical control, give the possibility to be able to cut, aluminum, uprights and slats of shutters.

Thanks to top-down cutting with guides and recirculating ball shoes, chipping is effectively reduced.

Automatic piece return

This device being incorporated inside the machine, does not affect the overall surface and avoids continuous movement by the operator, thus increasing productivity.

Cut off pieces warehouse

This simple but functional design trick reduces considerably the movements of the operator, allowing him to always be in an optimal position both for the loading and unloading functions.

Related machineries

BAUSOLA MULTITRON

Cutting-off

Cutting-off, defecting, optimising and chamfering machine for louvers of shutters

BAUSOLA MULTITRON

Cutting-off

Automatic cycle of cutting and chamfering.

Possibility of selecting many typologies in order to optimise (min waste, max length...).

Full of:

Vertical loader for louvers

Clamp pusher

Defect reading and self measurement of piece length

Upper blade

Returning of cut-off pieces to the operator with storage under the loader top

Automatic cutting-...

BAUSOLA STEKTRON

Cutting-off

Cutting-off, defecting, optimising and chamfering machine for louvers of shutters

BAUSOLA STEKTRON

Cutting-off

Suitable for working of louvers of shutters

Possibility of selecting many typologies in order to optimise (min waste, max length...)

Equipped with:

Vertical loader for louvers

Clamp pusher,defect reading and self measurement of piece length

Upper blade

Touch screen monitor with dedicated software

Possibility of loading distinct for offic...

Request infos

BAUSOLA UNITRON