—

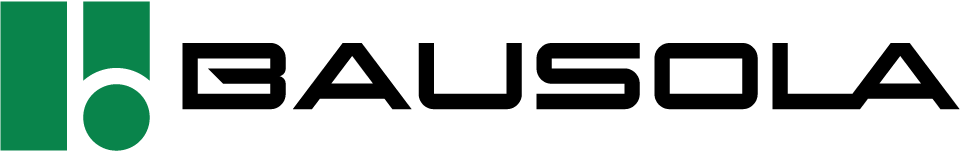

SIMAL

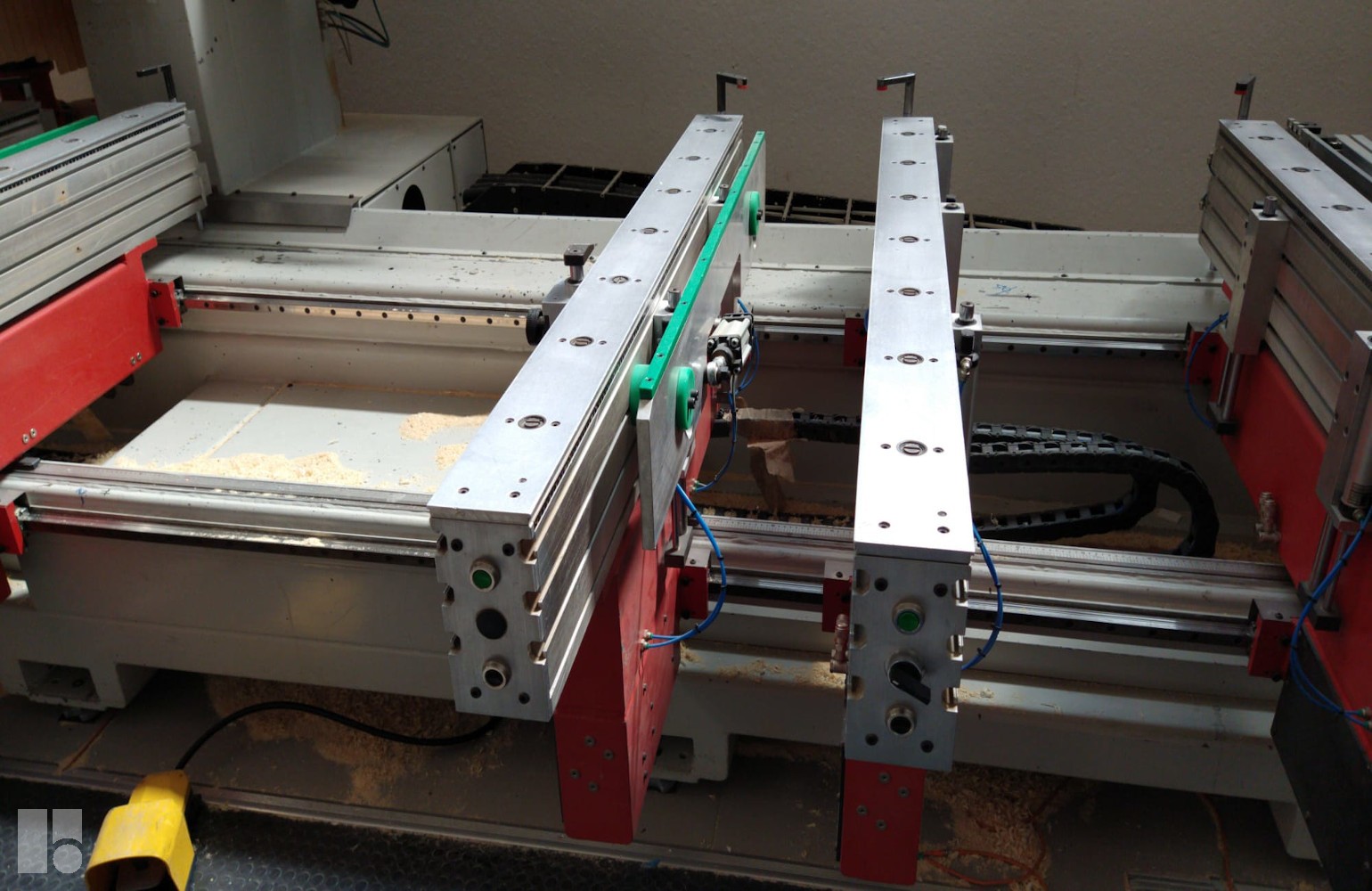

MODULO EVOLUTION

Numerical control machining center for working wooden windows, complete with anuba hinged head

Code: 1080

restore Production year: 2006 error_outline Status: Good

domain Availability: In stock check_circle EC legislation: Compliant

Controlled axes number:

3

Arms number:

6

Description

Numerical control machining center for working wooden windows, complete with anuba hinged head

SIMAL MODULO EVOLUTION

Milling, boring and chisel milling center on wooden or plastic and composite elements.

Structure in stabilized steel tubes. Sliding on casehardened and ground guides with recirculating ball bearings.

Axis movements with racks and recirculating ball screws.

N. 3 interpolated axes (X - Y - Z).

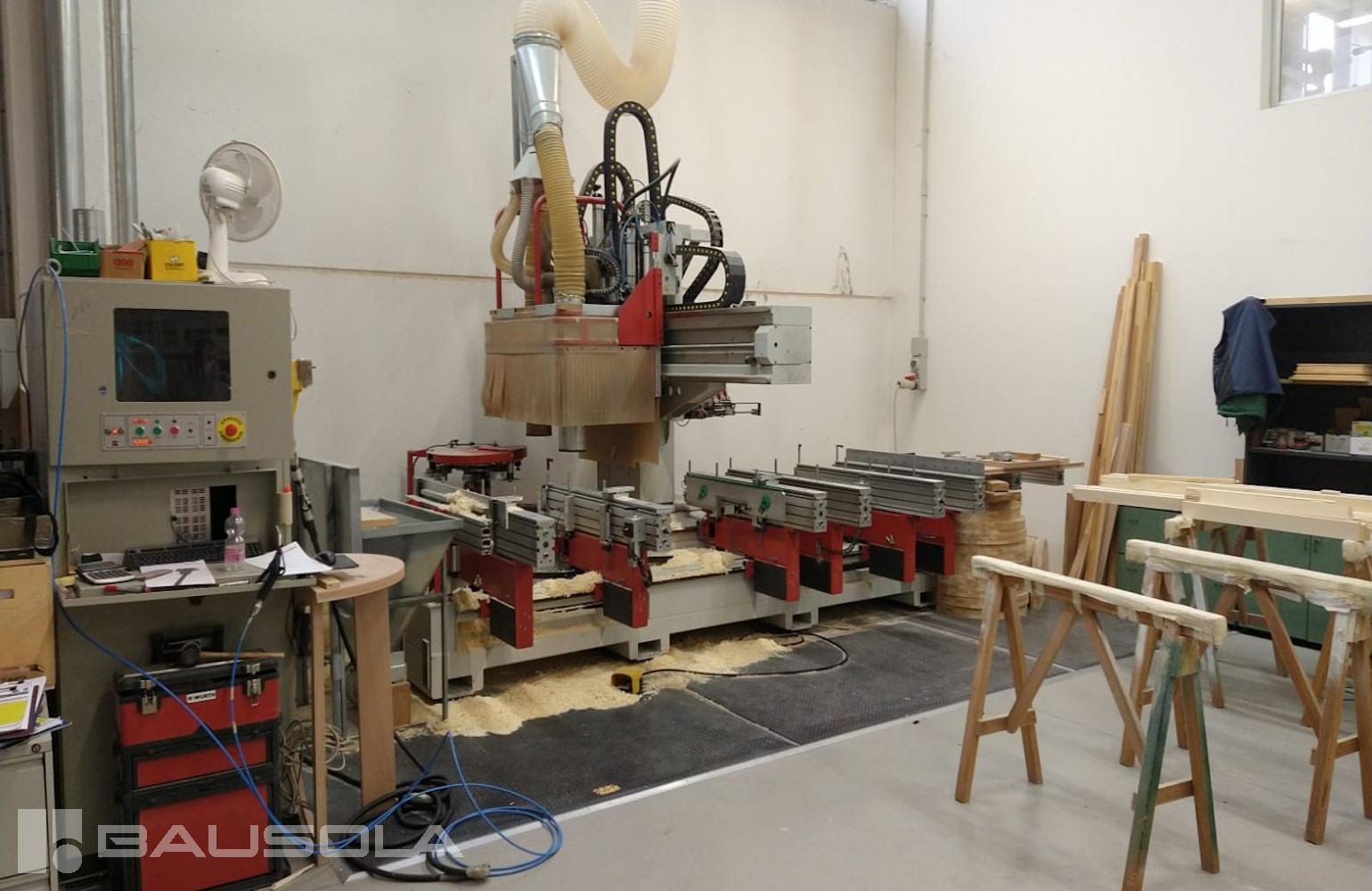

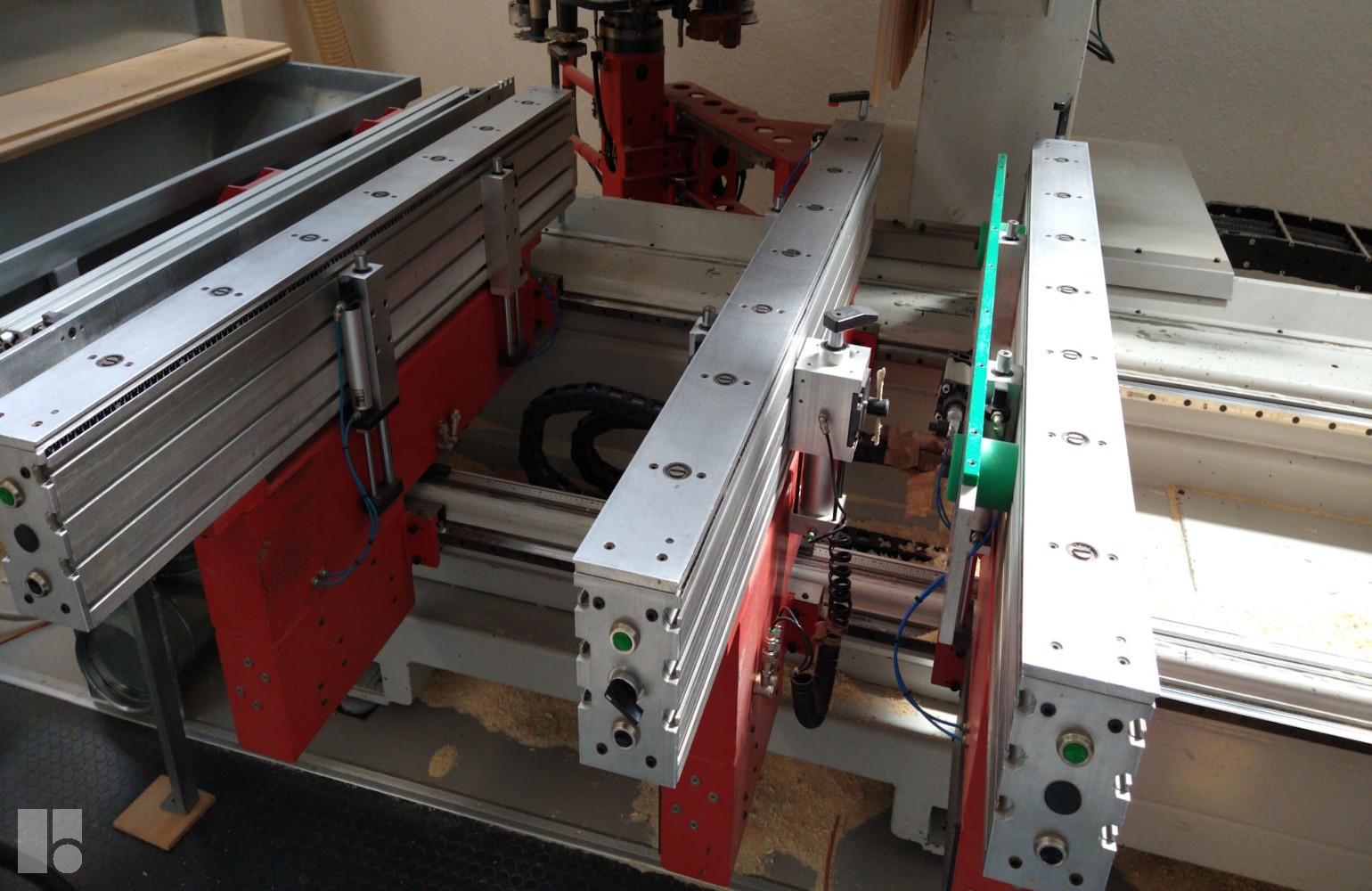

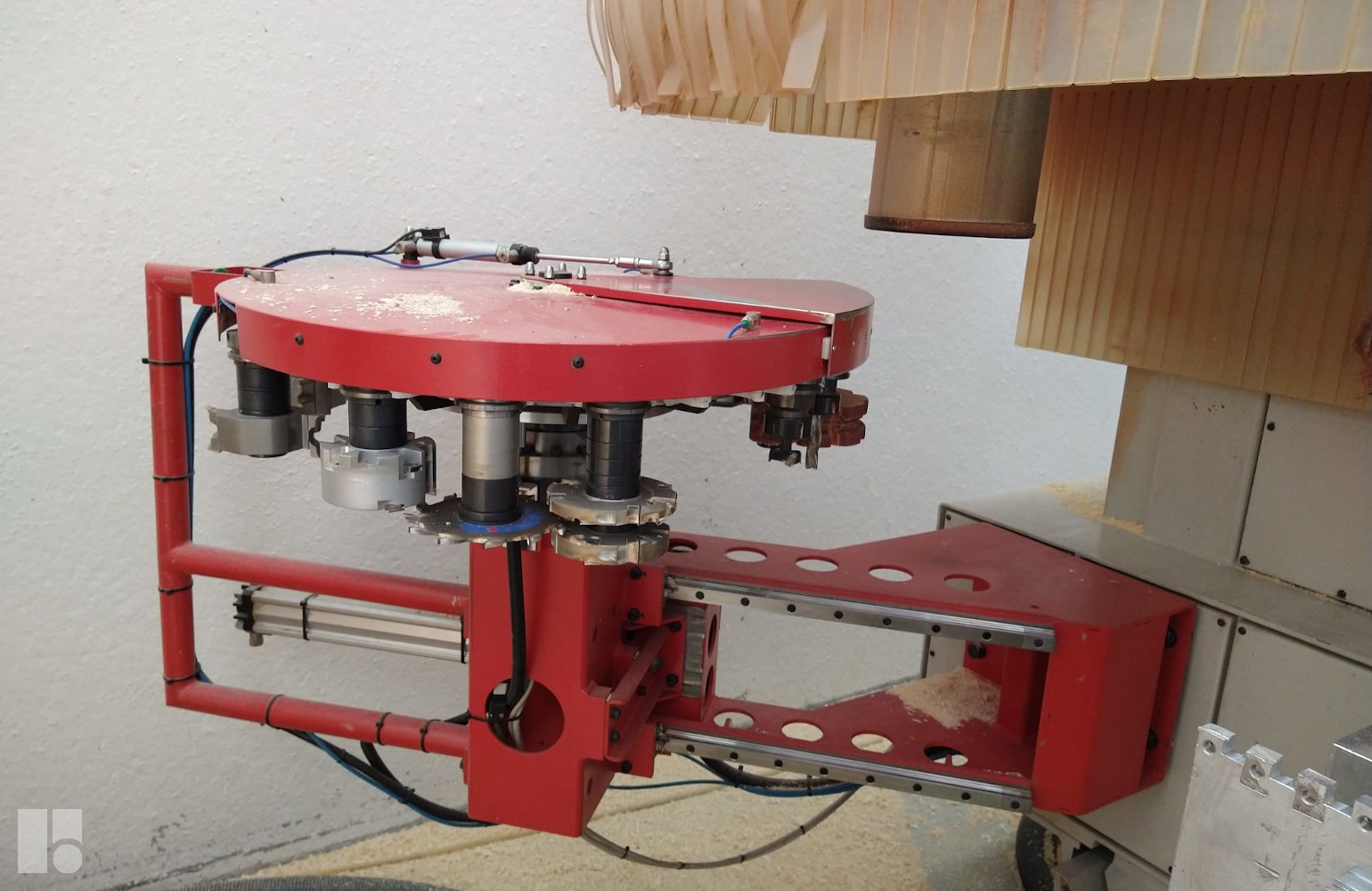

N. 1 HSK 63F electrospindle with 90° - 180° pneumatic control for vertical and horizontal break-in lock.

N. 1 Electrospindle Vertical ISO 30.

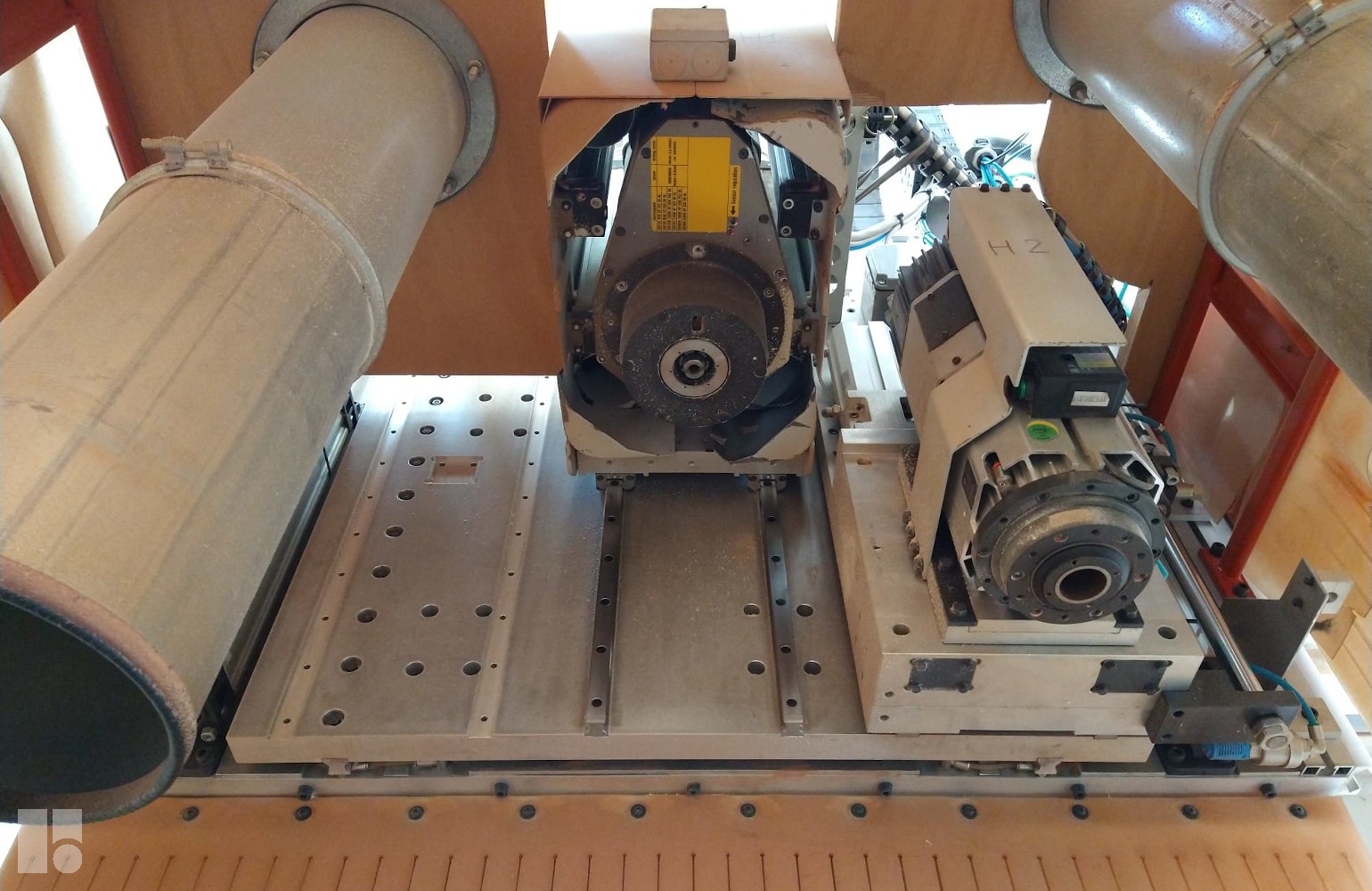

N. 1 Anuba head with inclination -10° + 90°

Technical details

Effective working

Effective X

3800 mm

Eeffective Y

1600 mm

Effective Z

350 mm

Details

Heads number

2

Controlled axes number

3

Main motor power

18 kW

Mils connection drive motor

HSK 63F

Anuba hinge unit

check_circle

Tools warehouse positions number

18

Arms number

6

Suction quantity

15

Grips number (Optional)

8

Security

SecurityPressure-sensitive (sensing) safety mats

Vacuum pump

1 x 100 m3/h

Software/C.N.

Software

Dedicated

Generals

Sizes*

5000 x 2400 x 2600 mm

Weight*

5000 kg

Total kW*

18

*Shown values may vary depending on the configuration of the machine.

Related machineries

LARI e LARI FR10 TA

CNC / Pantographs

NC Machining Centre for milling, notching and cutting operations on wooden or plastic and composite parts

LARI e LARI FR10 TA

CNC / Pantographs

Structure in stabilised tubular steel.

Running on casehardened and ground guides with bearings with 4 ball re-circulations.

Axis movements with racks and ball re-circulation screws with Brushless and Direct Current motors.

Main electric chuck 3,0 HP. 2,2 kw. at 18.000 rpm ER 25 gripper coupling.

Variable rpm by Inverter.

3 interpolated axes.

5 controlled axes.

FELDER - FORMAT4 profit H22 XYLMAC

CNC / Pantographs

Machining center for windows and doors

FELDER - FORMAT4 profit H22 XYLMAC

CNC / Pantographs

The base of the H22 profit machining center is made up of high-thickness, electrically welded tubular sections.

X-axis guide system:

The X-axis arm is driven by a rack with inclined and curved teeth.

Y-axis guide system:

The Y axis is positioned with a ground ball screw.

Z axis sliding system:

The Z ...

LARI e LARI FR30 TA

CNC / Pantographs

Numerical control machining centre

LARI e LARI FR30 TA

CNC / Pantographs

Numerical control machining centre for milling operations, notching or cutting on wooden, plastic or composite parts.

Structure in stabilised tubular steel.

Running on ground guides with 4 ball recirculations.

Axis movements with BRUSHLESS/DIRECT CURRENT motors.

Main electric chuck 4.5 HP at 18,000 rpm..

Variable rpm by Inverter.

3 interpolated axes

Industr...

MASTERWOOD TEKNOMAT 2004 F

CNC / Pantographs

Numerically controlled milling/anuba head machine

MASTERWOOD TEKNOMAT 2004 F

CNC / Pantographs

Top dimension mm 3300 x 260

Maximum distance between the 2 external anubas mm 2700

Maximum height with head positioned 0° mm 200

Maximum thickness with head positioned at 90° mm 120

Group of anubatura - Drilling motor Hp 1 - Screwing motor Hp 1

Tilt managed by control from -7° - +90°

Axis speed:

X axis m/min 40

Y axis m/min 7

Z axis m/min 7

Request infos

SIMAL MODULO EVOLUTION