—

FELDER - FORMAT4

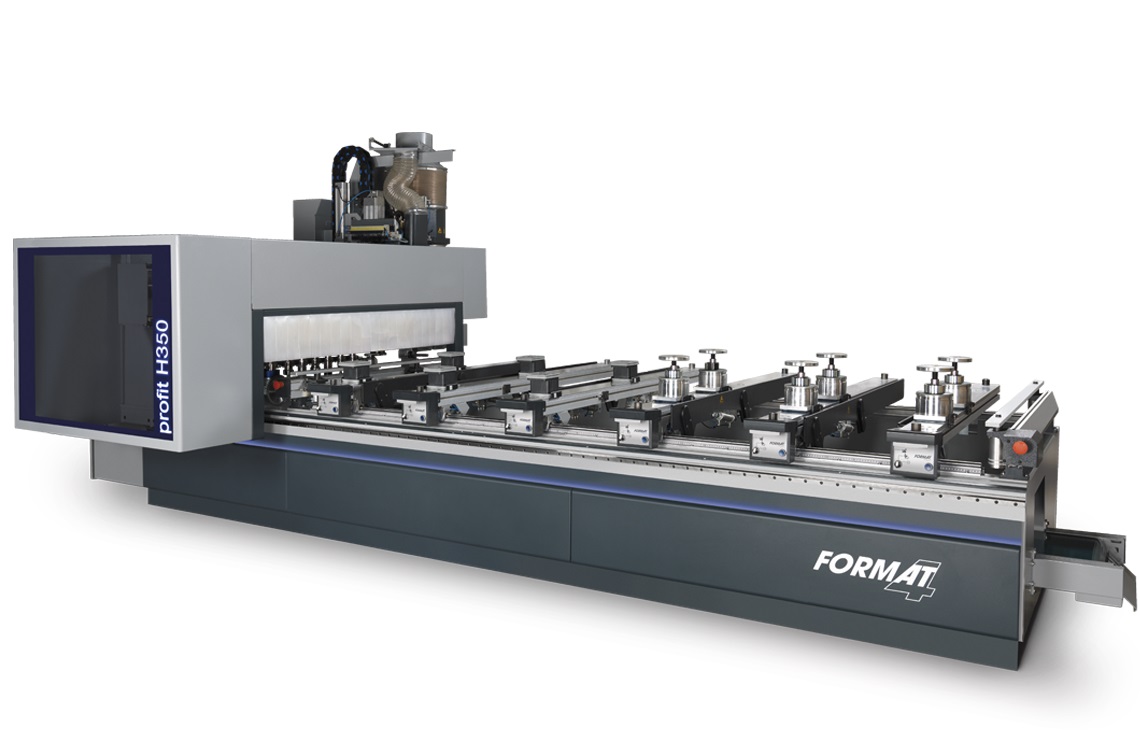

profit H350 - 16.30

5 axes CNC Machining Centre

Controlled axes number:

5

Boring head

Arms number:

6

Description

5 axes CNC Machining Centre

FELDER – FORMAT4 profit H350 – 16.30

Five axes for universal workshops

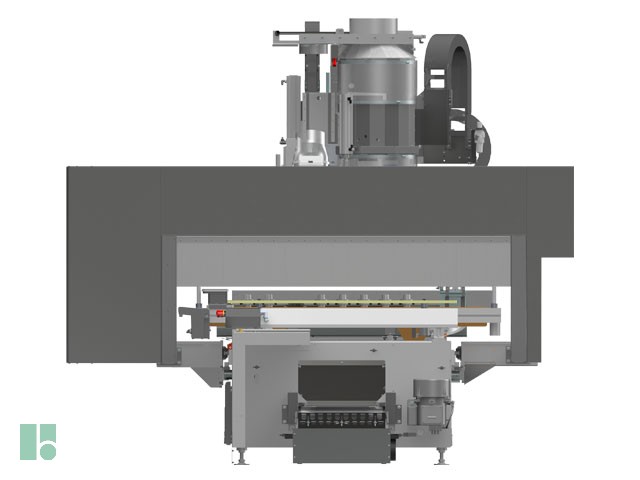

It is universal workshops in particular where 5 axes technology is becoming increasingly important. With just a few standard tools, a large as possible range of uses has to be covered, in order to keep the cost of investment in special units and milling tools as low as possible. The new profit H350 Format-4 CNC Machining Centre covers these requirements like no other and offers the most up-to-date 5 axes technology at a manageable investment level. The high performance main spindle guarantees excellent results at every angle regardless of the material. In conjunction with the 18 independent drilling spindles and integrated grooving saw aggregate, the profit H350 offers limitless processing possibilities and ensures shortest possible production cycles.

In the new, completely reengineered design, the CNC machining centres from Format-4 display dynamics, power and high end technology from the first glance. With the “everything from a single supplier” solutions from Format-4 the customer will receive a perfectly matched complete package for the highest of requirements.

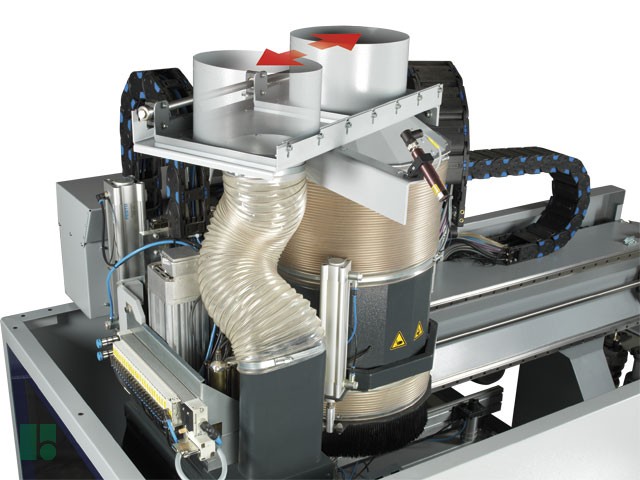

Small footprint – minimal space requirement!- 5 axes router spindle, solid construction with 12 kW liquid cooled motor

- Drawing = programming, intuitive operating software

- Software including 3D cabinet software “F4-Design” for presentation, parts list and connection to the machine

- Gantry design, synchronised drive, solid construction for maximum performance

- The drilling head covers the whole working field

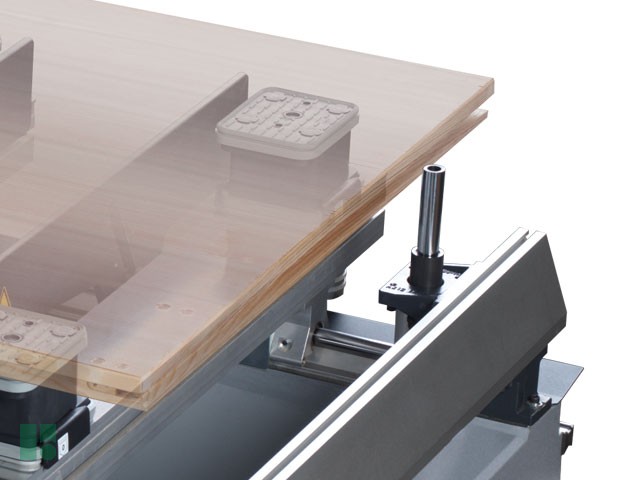

- High quality dual circuit vacuum clamping system with 100 mm vacuum pod height

- Large Y dimensions for maximum processing depth

- F4®Solutionsready

... FORMAT-4 Premium machines for premium requirements

- Tailor made financing solutions

- Constantly high performance in industrial continuous operation

- Customer specific optimised production solutions

- Solid design with premium components

- Many variations of specification packages with high-tech solutions

- Complete engineering precision

- Premium user comfort

- Award winning design

- Quality and precision from Austria

- Uncompromised productivity

- Perfect service package before, during and after the purchase

- Compliance with CE regulations

- Automation solutions

- Networked workshop

- Software and machines from a single supplier

Technical details

Effective working

Effective X

3000 mm (Optional 5000 mm)

Eeffective Y

1550 mm

Effective Z

250 mm (step height, see layout)

Details

Heads number

2

Controlled axes number

5

Main motor power

12 Kw (15 Optional)

Mils connection drive motor

HSK 63F

Boring head

check_circle

Tools warehouse positions number

12 + (18 Optional)

Arms number

6

Suction quantity

12

Grips number (Optional)

10

Security

Bumper

Vacuum pump

1 x 90 m3/h

Software/C.N.

Software

Woodflash

Generals

Sizes*

6750x4550x2600 mm

Weight*

4100 kg

Total kW*

22

*Shown values may vary depending on the configuration of the machine.

Performance package

- Increase of the maximum axis speeds by up to 30% in the X and Y directions

- Optimisation of positioning and rotation speeds by up to 80%

- Absolute encoder for absolute and continuous communication between machine and position sensor

- "Multitouch" function on the control terminal for user-friendly CNC machine operation

- Smooth, consistent and steady tool movements for best surface results on the finished workpiece

- Reduced vibration behaviour during CNC machining via the built-in jerk control

LightPos – LED vacuum pods positioning - revolutionary easy e precise. (Optional)

Staggered reference row

Maintenance opening

The main spindle: 5 axes - no restrictions

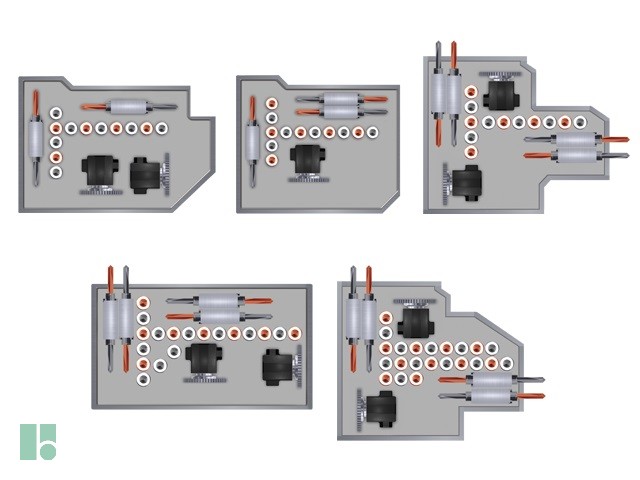

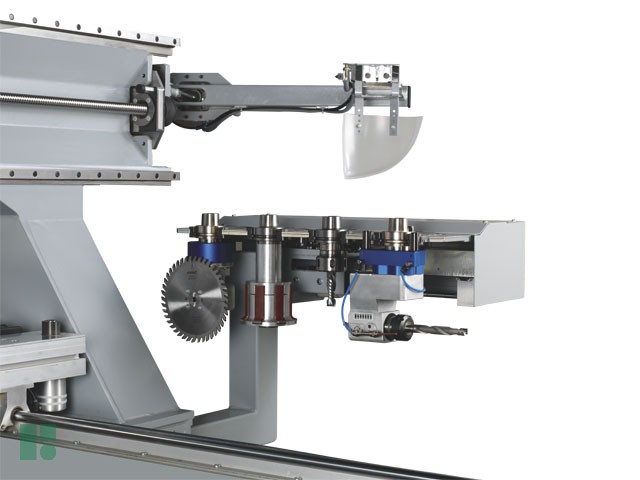

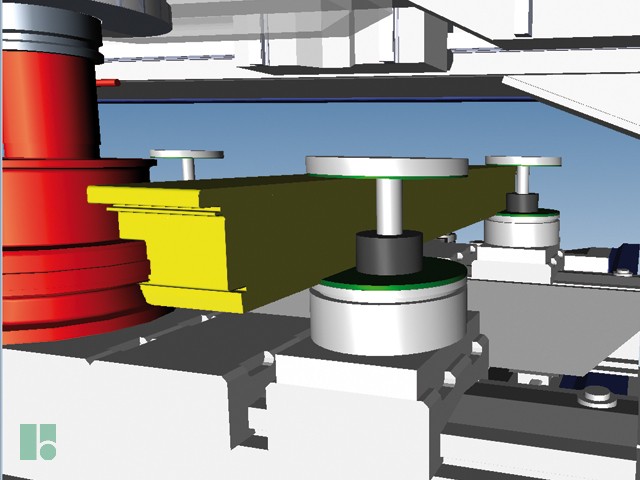

Limitless processing possibilities with the FORMAT-4 boring unit

- 12 vertical drilling spindles, 32 mm distance between spindles: each can be used individually

- 6 horizontal drilling spindles, spaced at 32 mm: 4 in the X and 2 in the Y axis, each can be used individually

- Integrated slot cutter in the X-axis

- Inverter controlled motor up to 7,500 rpm

- Highlight: The complete working field can be covered by the drilling head for vertical and horizontal drilling

Individual drill head configuration

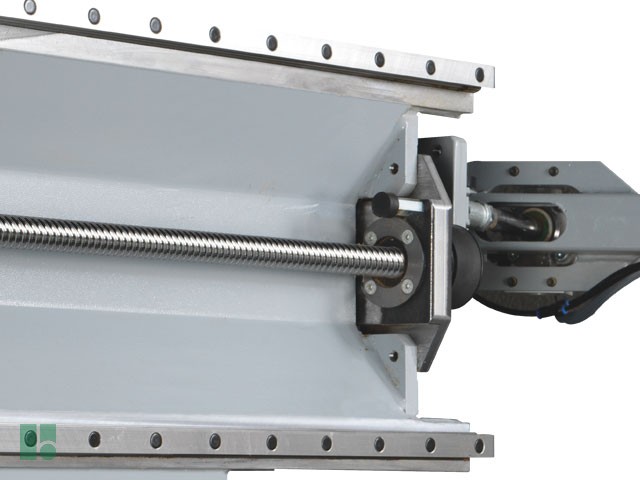

Rotary tool changer, mounted to the outrigger

Linear guides

Automatic central lubrication system

Secure workpiece support – precise results

Positioning display of consoles and vacuum pods

Workpiece feeding rails

Chip conveyor (Optional)

Workpiece feeding rails

Chipping deflection plate (Optional)

Extraction connection

Length measurement system (Optional)

Panel activation

12 position linear tool changer

4 position linear tool changermoving in the X-axis direction (Optional)

CNC machining centre with gantry design

Two different sized working fields for individual requirements

profit H350 16.50: X= 5000 mm - Y= 1580 mm - Z= 250 mm (Passage height from console height)

Variable position controlled extraction hood

Saw blade changer

Status indicator (Optional)

3D simulator with collision control (Optional)

Related machineries

VITAP K2 2.0

CNC / Pantographs

Welcome to the "BAR NESTING REVOLUTION", all the nesting advantages and without limits in the execution of horizontal holes.

Switching from high production to "JUST IN TIME" requires a review of production methods, and cost reduction in order to respond to a continuing changing market.

New linear automatic tool changer magazine and large Y axis 1250...

FELDER - FORMAT4 profit H100 22.43

CNC / Pantographs

Nesting CNC Machining Center, Ideal for woodworking, plastic and composite materials

FELDER - FORMAT4 profit H100 22.43

CNC / Pantographs

The panel cutting, drilling and milling centre for future-proof carpentry and joiner's workshops. Entire custom-made furniture with all holes, grooves and connections are produced in one single operation. The latest nesting technologies ensure the highest possible material and time savings. The profit H100 can be extended to full automation with different loading and unloading solutions, thus achi...

FELDER - FORMAT4 profit H150 22.43

CNC / Pantographs

Nesting CNC Machining Center, Ideal for woodworking, plastic and composite materials

FELDER - FORMAT4 profit H150 22.43

CNC / Pantographs

The panel cutting, drilling and milling centre for future-proof carpentry and joiner's workshops. Entire custom-made furniture with all holes, grooves and connections are produced in one single operation. The latest nesting technologies ensure the highest possible material and time savings. The profit H100 can be extended to full automation with different loading and unloading solutions, thus achi...

Request infos

FELDER – FORMAT4 profit H350 – 16.30