Controlled axes number:

3

Boring head

Description

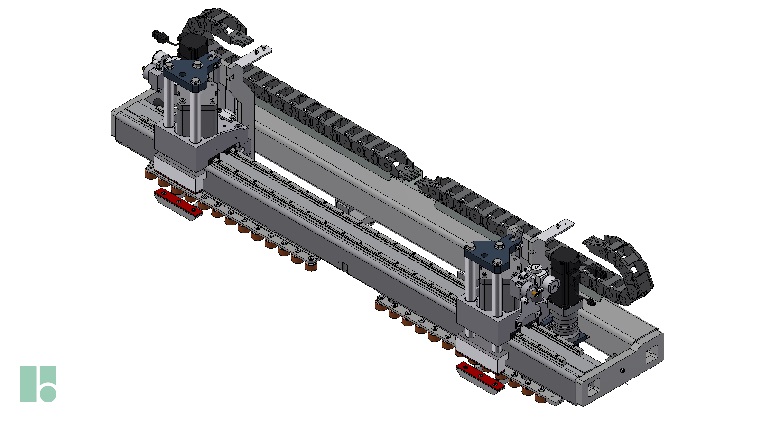

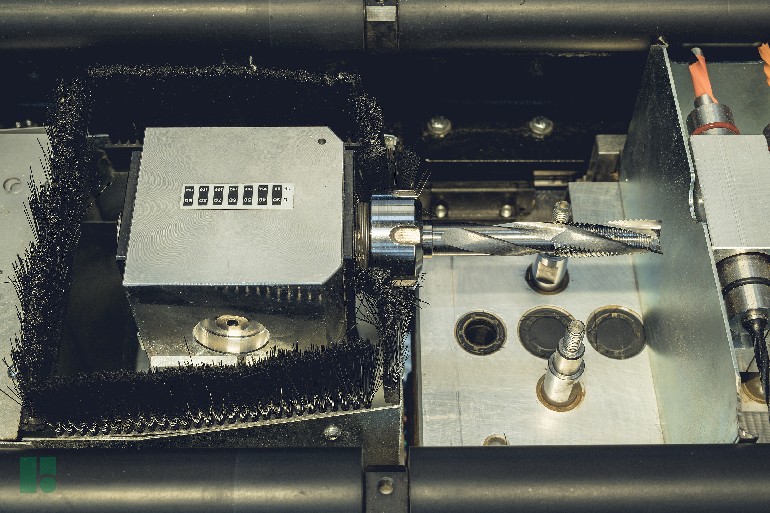

CNC Boring center

VITAP K2 2.0

Welcome to the "BAR NESTING REVOLUTION", all the nesting advantages and without limits in the execution of horizontal holes.

Switching from high production to "JUST IN TIME" requires a review of production methods, and cost reduction in order to respond to a continuing changing market.

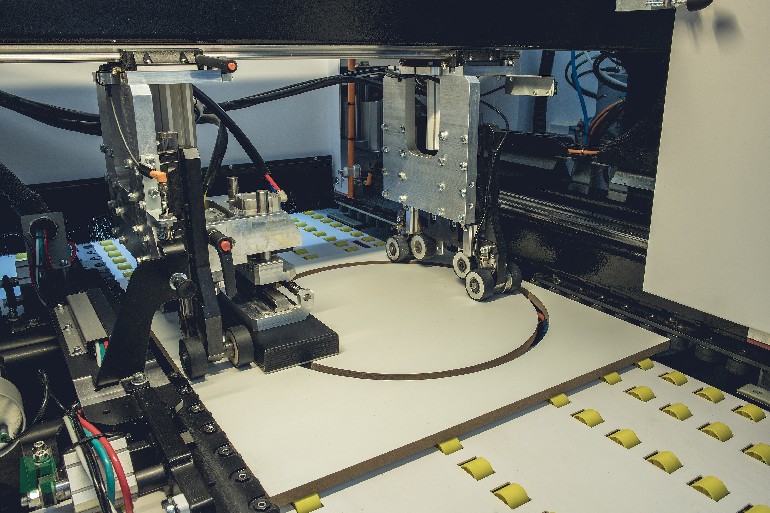

New linear automatic tool changer magazine and large Y axis 1250 mm capacity.

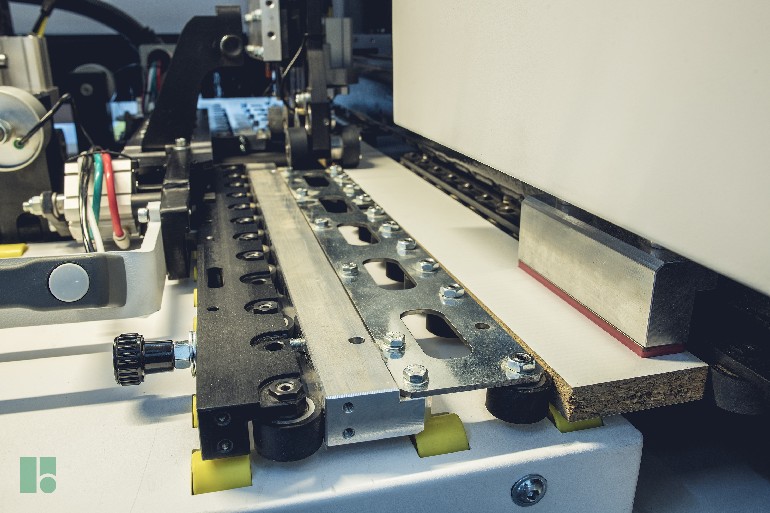

Patented D-D-T- Revolutionary seamlessly. Panel movement by 2 claps "SAVE TIME".

Maximun panel locking. Panel thickness min. 3 mm - max. 50 mm.

4 sides milling device 0-3 mm.

Vitap Bar Nesting System.

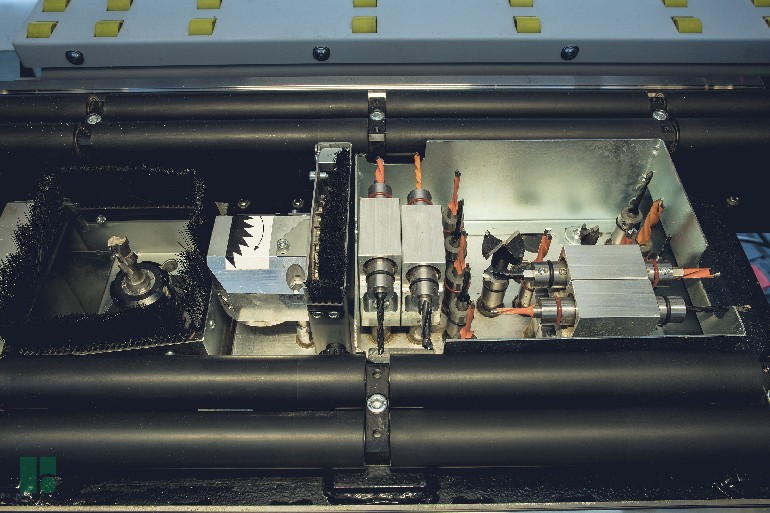

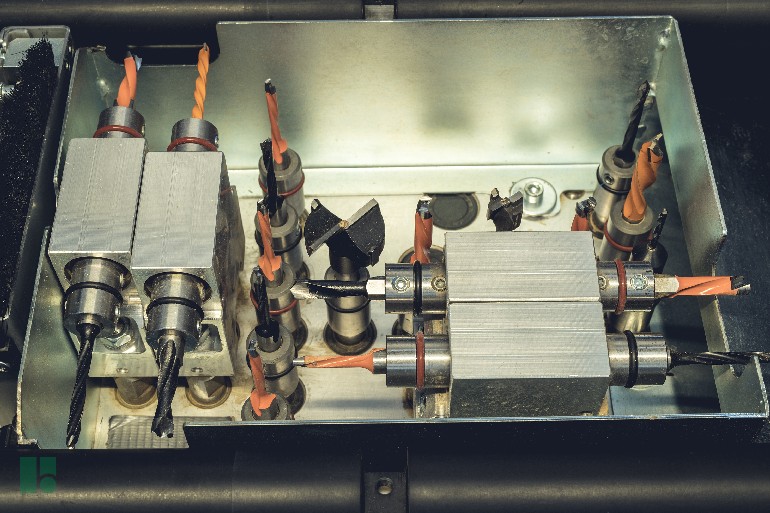

12 Number of vertical indipendent spindles.

2 + 2 number of horizontal spindles on axis X.

2 + 2 number of horizontal spindles on axis Y.

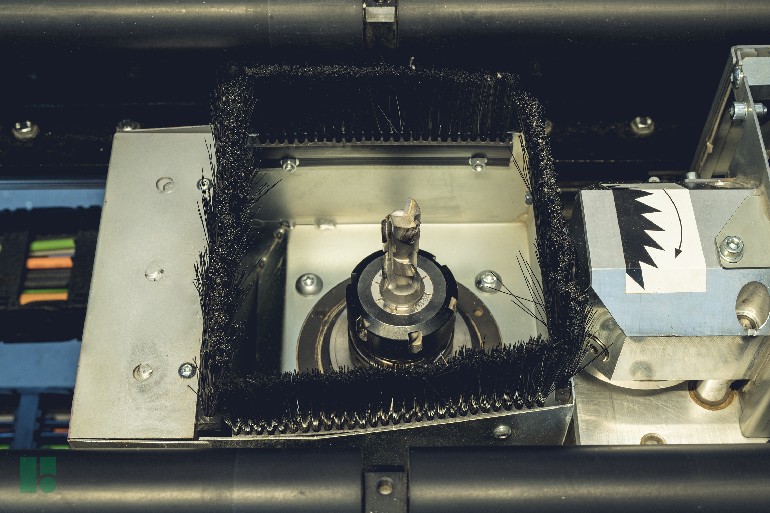

N. 1 Saw blade unit Ø 100 mm.

N. 1 Router head 5 kW ISO 30.

Optional:

- Vitap free Nesting System for perfect cutting inside of the panel

- Lamello Clamex P

- Horizontal milling

Technical details

Effective working

Effective X

+ 3500 mm

Eeffective Y

1250 mm

Effective Z

50 mm

Details

Heads number

2

Controlled axes number

3

Main motor power

5 Kw

Mils connection drive motor

ISO 30

Boring head

check_circle

Tools warehouse positions number

4

Grips number (Optional)

2 Automatic

Security

Cabina

Software/C.N.

Software

TPA + CABINET (MOBILE Optional)

Generals

Sizes*

2900x1650x1890 mm

Weight*

950 kg

Total kW*

7

*Shown values may vary depending on the configuration of the machine.

Patented D-D-T- Revolutionary seamlessly

Maximun panel locking. Panel thickness min. 3 mm - max. 50 mm.

Patented D-D-T- Revolutionary seamlessly

New linear automatic tool changer magazine

New linear automatic tool changer magazine

4 sides milling device 0-3 mm

Vitap free Nestyng System

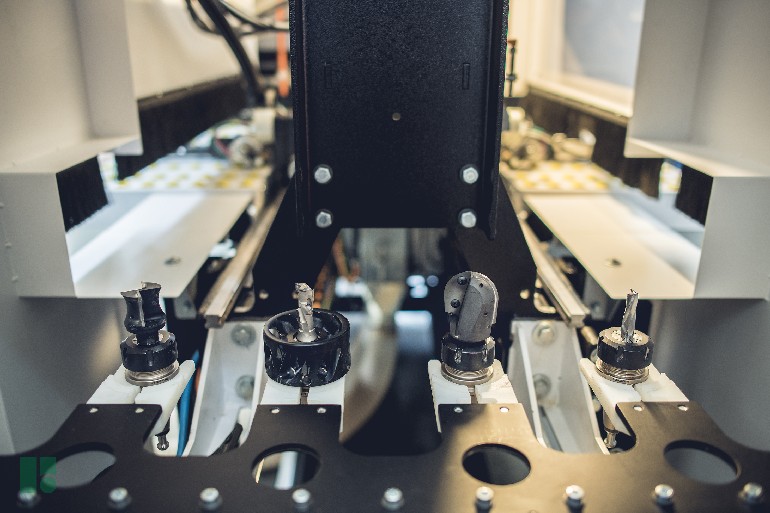

Operating Head

- Vertical independent spindles = 12

- Horizontal spindles on axis X X = 2+2

- Horizontal spindles on axis Y = 1+1

- N. 1 Saw d. 100 mm

- N. 1 Router head 3,6 Kw ISO 30

Vertical independent spindles

Router head 3,6 Kw ISO 30

Horizontal Milling (Optional)

Related machineries

FELDER - FORMAT4 profit H150 22.43

CNC / Pantographs

Nesting CNC Machining Center, Ideal for woodworking, plastic and composite materials

FELDER - FORMAT4 profit H150 22.43

CNC / Pantographs

The panel cutting, drilling and milling centre for future-proof carpentry and joiner's workshops. Entire custom-made furniture with all holes, grooves and connections are produced in one single operation. The latest nesting technologies ensure the highest possible material and time savings. The profit H100 can be extended to full automation with different loading and unloading solutions, thus achi...

FELDER - FORMAT4 profit H08 - 21.31

CNC / Pantographs

Nesting CNC Machining Centre

FELDER - FORMAT4 profit H08 - 21.31

CNC / Pantographs

CNC-NESTING – EFFICIENCY THROUGH AUTOMATION

Especially developed for universal application, this profitable CNC all-rounder convinces with top precision and impressive productivity when processing various different materials.

The profit H08 21.31 offers maximum flexibility and efficiency and already convinces in the basic equipment with 15 tool positions. For perf...

FELDER - FORMAT4 profit H350 - 16.30

CNC / Pantographs

5 axes CNC Machining Centre

FELDER - FORMAT4 profit H350 - 16.30

CNC / Pantographs

Five axes for universal workshops

It is universal workshops in particular where 5 axes technology is becoming increasingly important. With just a few standard tools, a large as possible range of uses has to be covered, in order to keep the cost of investment in special units and milling tools as low as possible. The new profit H350 Format-4 CNC Machining Centre covers these re...

FELDER - FORMAT4 profit H100 22.43

CNC / Pantographs

Nesting CNC Machining Center, Ideal for woodworking, plastic and composite materials

FELDER - FORMAT4 profit H100 22.43

CNC / Pantographs

The panel cutting, drilling and milling centre for future-proof carpentry and joiner's workshops. Entire custom-made furniture with all holes, grooves and connections are produced in one single operation. The latest nesting technologies ensure the highest possible material and time savings. The profit H100 can be extended to full automation with different loading and unloading solutions, thus achi...

Request infos

VITAP K2 2.0